Mechanical testing device for sliding pipe bus support fittings

A technology of mechanical testing and sliding tubes, which is applied in the testing of mechanical components, measuring devices, and testing of machine/structural components. problems, to achieve the effect of convenient mechanical test operation, easy operation, and overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

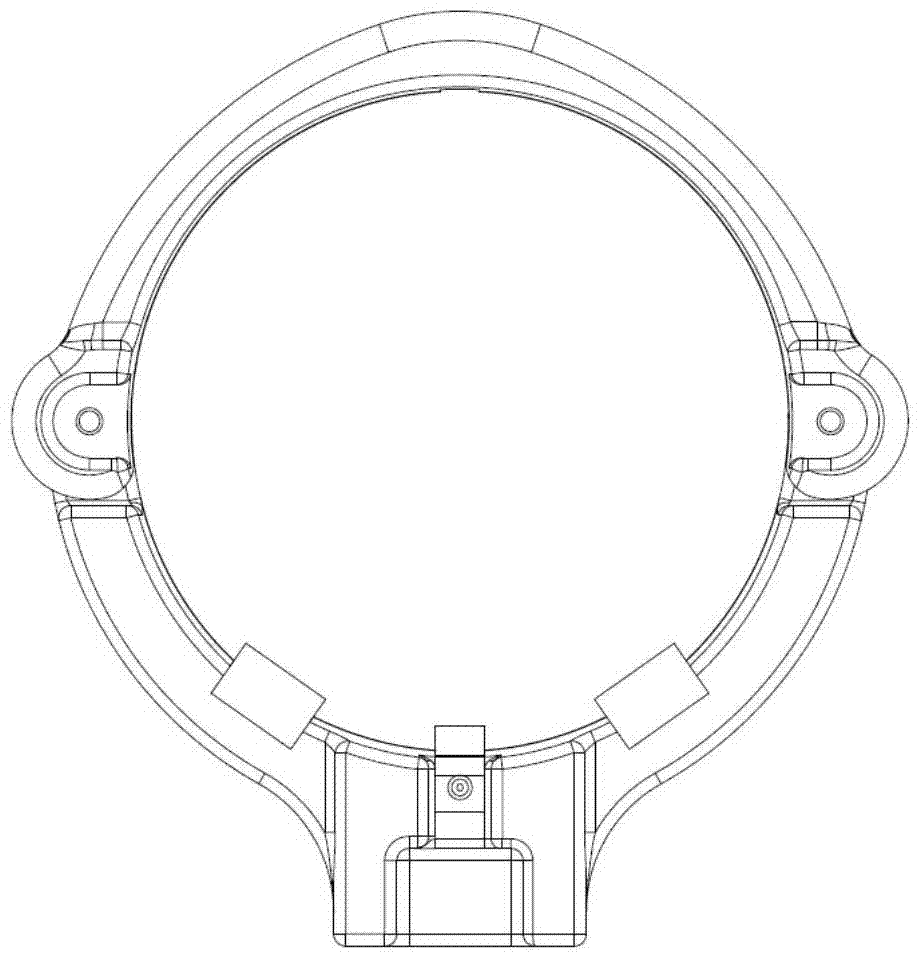

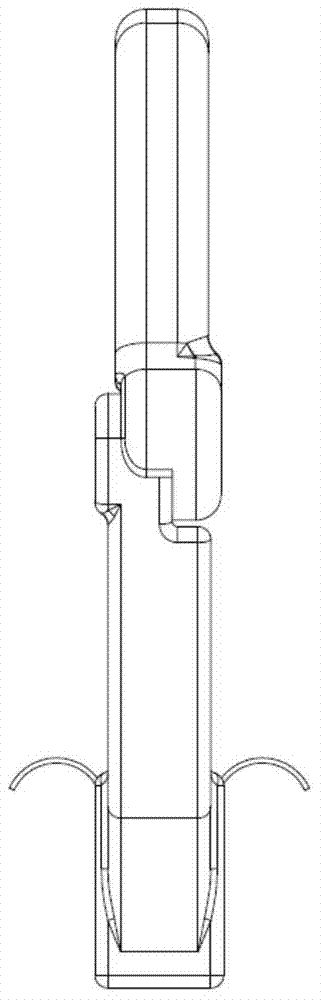

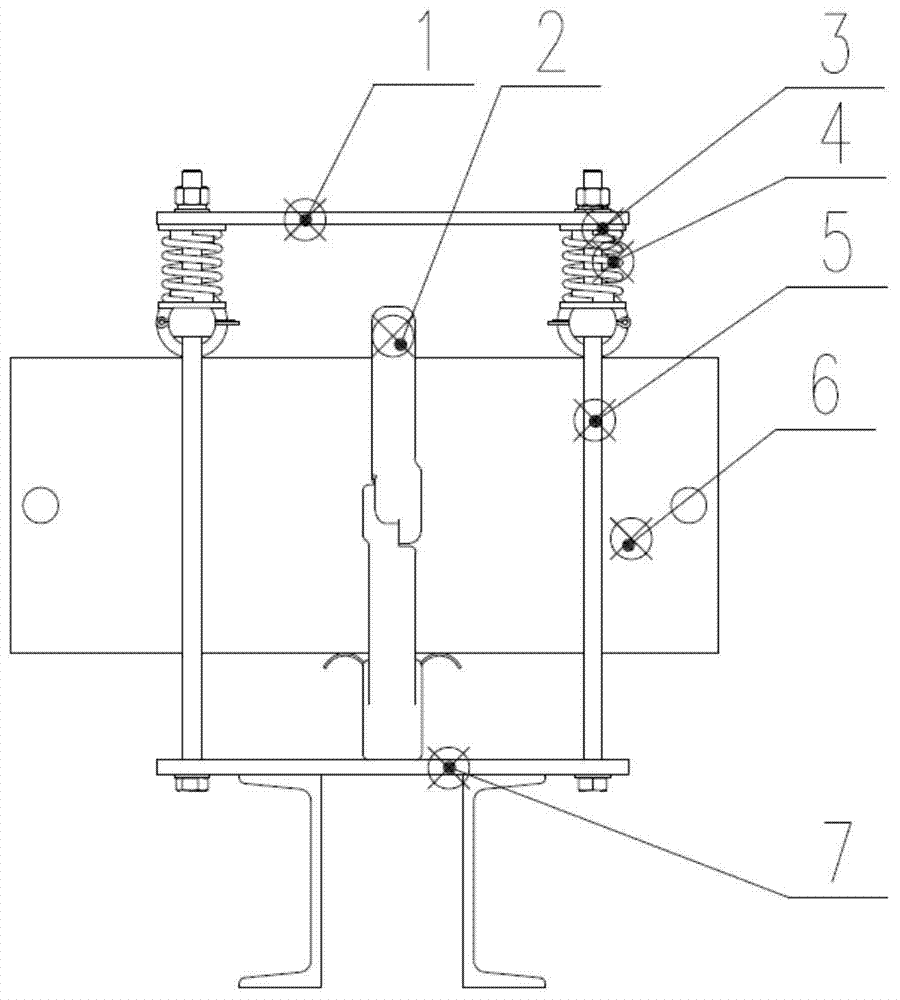

[0025] Such as Figure 1-9 As shown, a mechanical test device for a sliding tube support fitting includes a test base 7, and the test base 7 is provided with a mounting structure for a sliding tube support fitting. The mounting structure can be a through hole or a mounting plate, etc., and the sliding tube The female supporting hardware is fixed on the above-mentioned test base 7 through the above-mentioned installation structure. Two sets of pressure devices are provided on both sides of the above-mentioned installation structure, and these two sets of pressure devices include a support mechanism, a pressure spring 4, a pipe mother pressure transmission part 8 and a limit device. Both groups of pressure devices are fixed on the test base 7 through the above-mentioned support mechanism. The above-mentioned support mechanism includes two screw rods 5 vertically fixed on the test base 7. The two screw rods 5 corresponding to each group of pressure devices pass through The throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com