A method for evaluating the hydration resistance of alkaline refractories

A refractory and hydration-resistant technology, applied in the direction of material resistance, can solve the problems of large evaluation error, hydration resistance of difficult-to-alkali refractories, and long evaluation period, and achieve simple evaluation methods, shorten the detection period, Evaluate a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

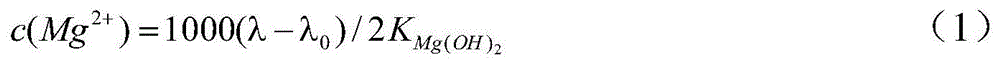

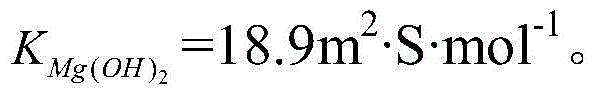

[0051] A method for evaluating the hydration resistance of basic refractories containing MgO. The specific steps of the evaluation method are:

[0052] The first step is to crush the basic refractory material to 1-2 mm to obtain basic refractory material pellets.

[0053] Step 2: Weigh 1-3g of alkaline refractory granules and pour them into the first beaker, then measure the conductivity λ of the water to be poured into the first beaker 0 7.3×10 -4 S / m, and then add the water into the first beaker according to the mass ratio of the basic refractory material particles to the water is 1: (500-600).

[0054] In the third step, the first beaker after adding water is placed in a constant temperature drying oven at 25-30° C., and left to stand for 0.45-0.50 hours.

[0055] Step 4: Take out the first beaker and filter; then pour the filtered hydration solution into the second beaker, place it in a constant temperature drying oven at 25-30°C, and let it stand for 2-3 hours; take ou...

Embodiment 2

[0068] A method for evaluating the hydration resistance of basic refractories containing MgO. The specific steps of the evaluation method are:

[0069] The first step, with the first step of embodiment 1.

[0070] Step 2: Weigh 1-3g of alkaline refractory granules and pour them into the first beaker, then measure the conductivity λ of the water to be poured into the first beaker 0 6.8×10 -4 S / m, and then add the water into the first beaker according to the mass ratio of the basic refractory material granules to the water is 1: (600-700).

[0071] The third step is to place the first beaker after adding water in a constant temperature drying oven at 25-30° C., and let it stand still for 0.35-0.40 hours.

[0072] Step 4: Take out the first beaker and filter; then pour the filtered hydration solution into the second beaker, place it in a constant temperature drying oven at 25-30°C, and let it stand for 2-3 hours; take out the second beaker, Detect that the conductivity λ of t...

Embodiment 3

[0079] A method for evaluating the hydration resistance of basic refractories containing MgO. The specific steps of the evaluation method are:

[0080] The first step, with the first step of embodiment 1.

[0081] Step 2: Weigh 2-4g of alkaline refractory granules and pour them into the first beaker, then measure the conductivity λ of the water to be poured into the first beaker 0 9.6×10 -4 S / m, and then add the water into the first beaker according to the mass ratio of the basic refractory material granules to the water is 1: (550-650).

[0082] The third step is to place the first beaker after adding water in a constant temperature drying oven at 25-30° C., and let it stand still for 0.30-0.35 hours.

[0083] Step 4: Take out the first beaker and filter; then pour the filtered hydration solution into the second beaker, place it in a constant temperature drying oven at 25-30°C, and let it stand for 2.5-3.5 hours; take out the second beaker, Detect that the conductivity λ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com