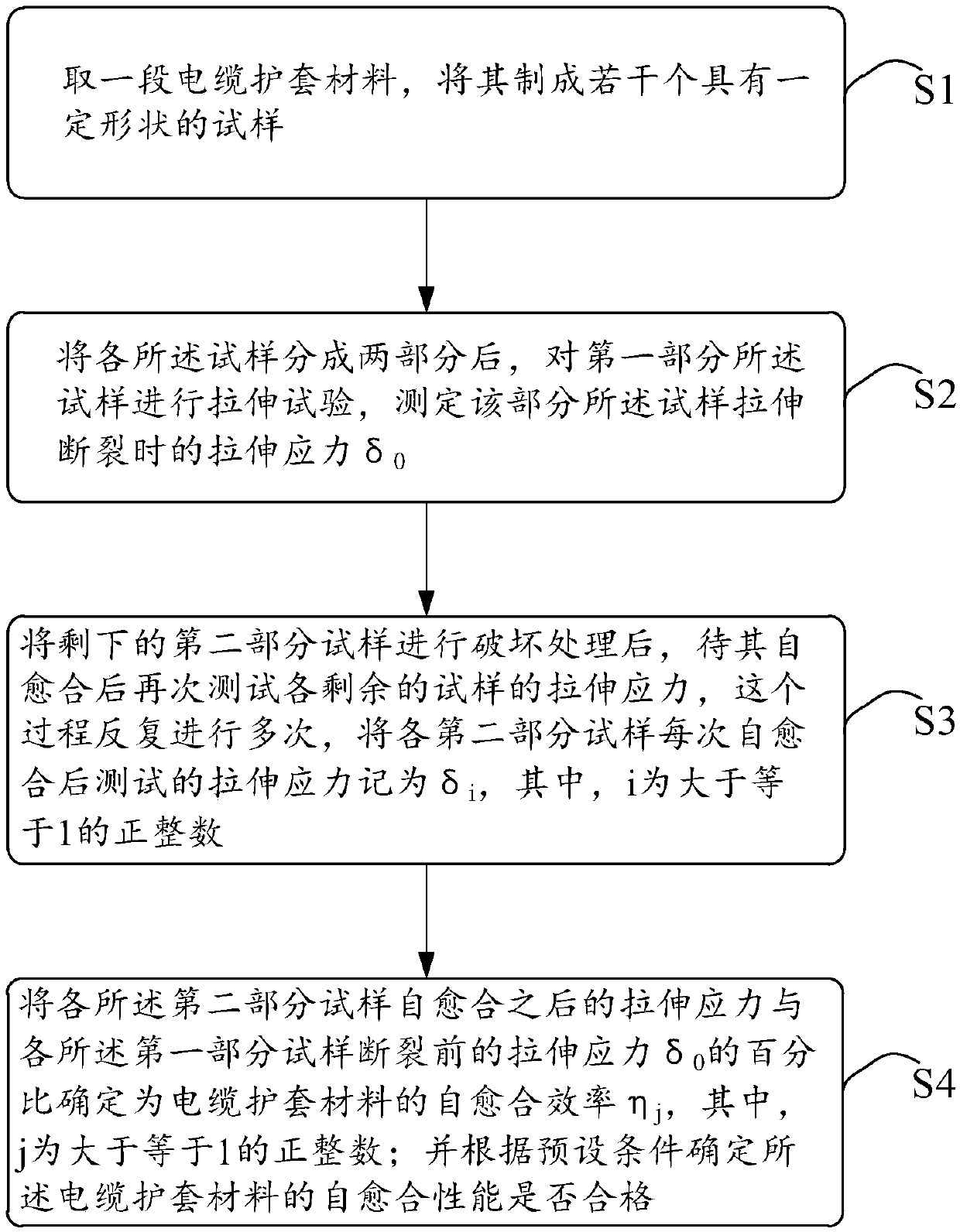

Method for evaluating self-healing property of cable sheath material

A cable sheathing and evaluation method technology, which is applied in the direction of analyzing materials, using stable tension/pressure to test the strength and strength characteristics of materials, etc. Service life and the effect of reducing resource loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

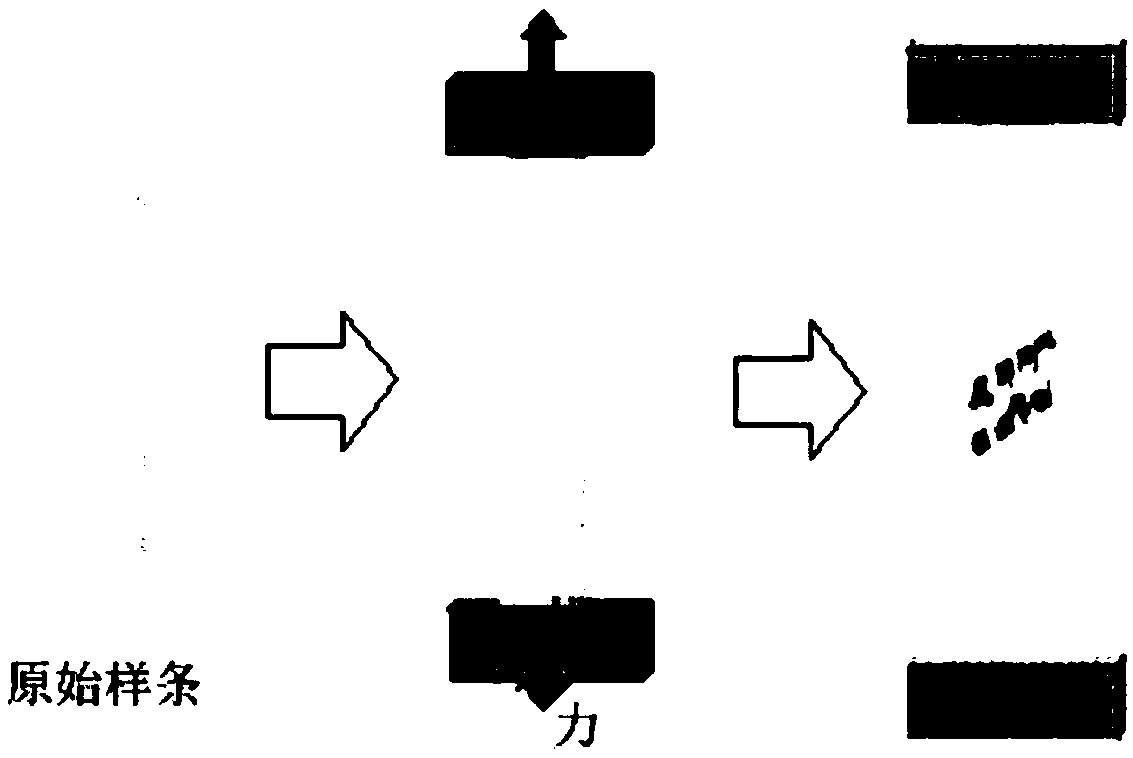

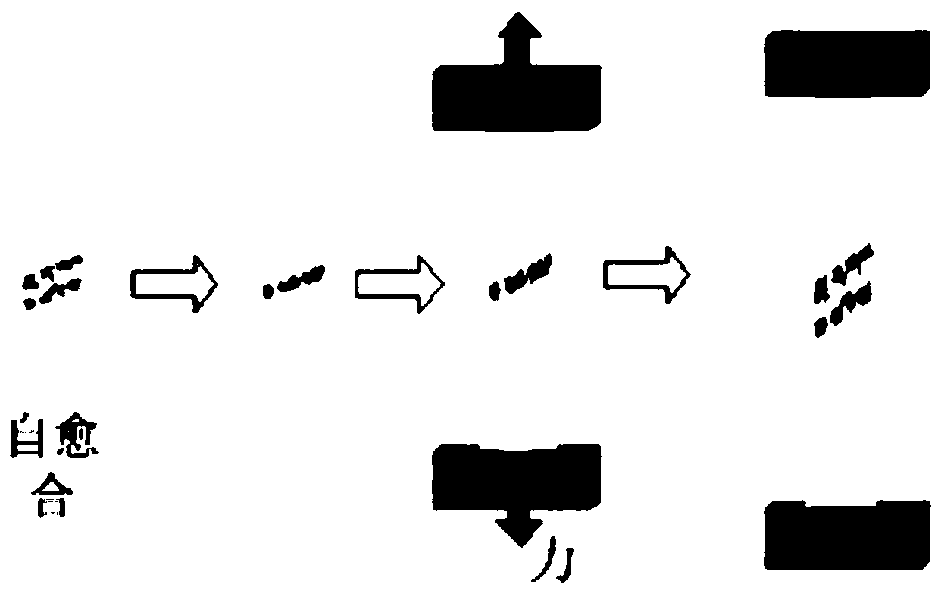

Examples

Embodiment 1

[0051] Divide the cable sheath material into 3 samples. The arithmetic mean value of the tensile stress of each sample before damage is 1.1452MP1804997a. After cutting off the sample, put the two ends of the wound in contact with each other, wait for 2 hours at room temperature, and then use The arithmetic mean δ of the tensile stress of each sample after the first healing is determined by the universal tensile testing machine 1 is 1.0956MP1804997a, and finally calculated the self-healing efficiency η of the sample 1 is 95.66%.

Embodiment 2

[0053] The sample in embodiment 1 is disconnected from the original position, re-healed, and measure the tensile stress δ of healing for the second time 2 is 1.0064MP1804997a, and the self-healing efficiency η of the sample is finally calculated 2 was 87.87%.

Embodiment 3

[0055] The sample in embodiment 1 is disconnected from the original position again, and healed again, measure the tensile stress δ of healing for the third time 3 is 0.9468MP1804997a, and finally calculated the self-healing efficiency η of the sample 3 was 82.67%.

[0056] It can be seen from the above examples that the self-healing evaluation method provided by the present invention performs multiple damage treatments on the cable sheath material in order to obtain accurate tensile stress and ensure the accuracy of the evaluation results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com