Processing system and processing method

一种加工系统、加工方法的技术,应用在全面工厂控制、输送机物件、电气元件等方向,能够解决降低生产成本、耗费人力、工件载具数量的需求大等问题,达到提升生产效率、节省人力需求、降低生产成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

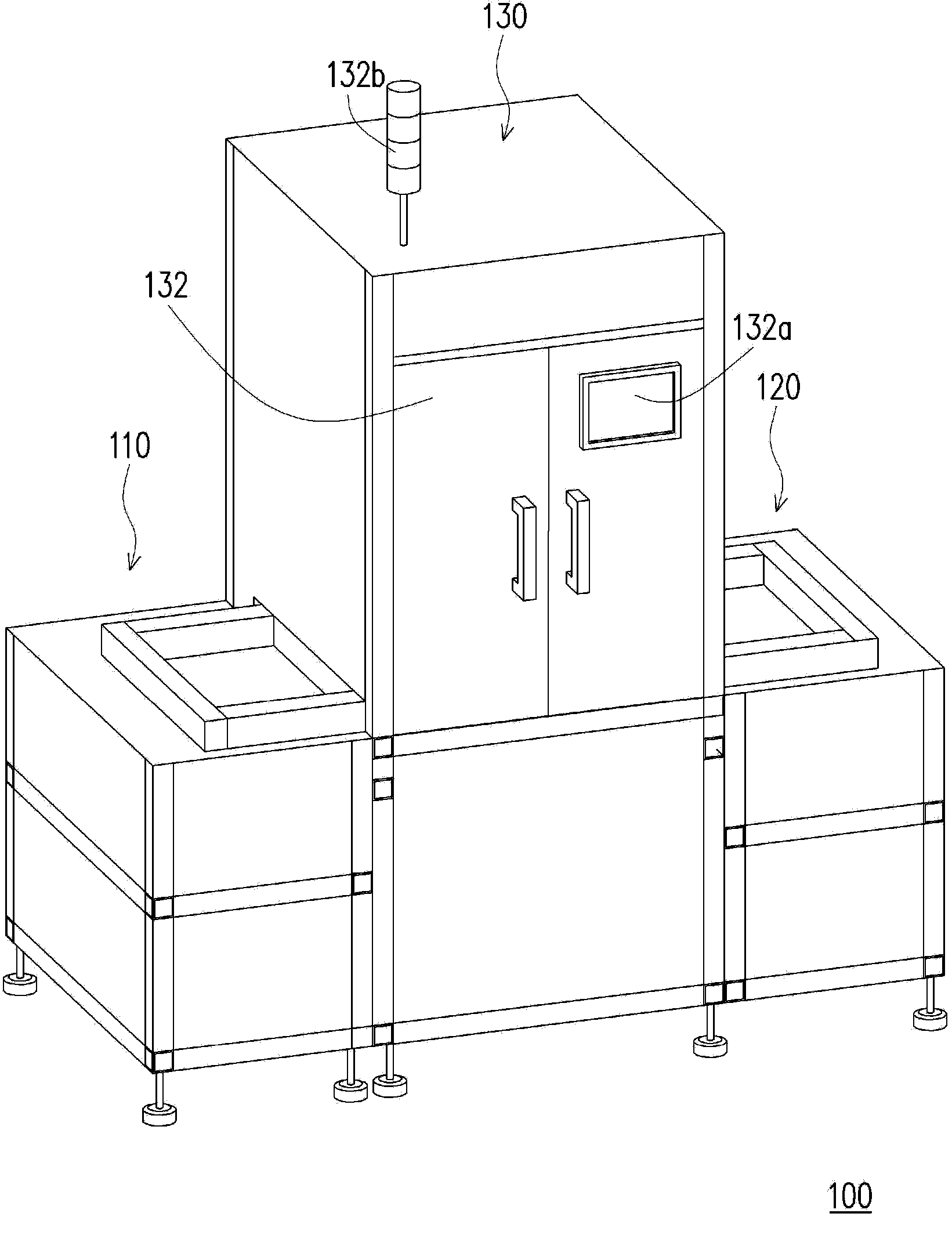

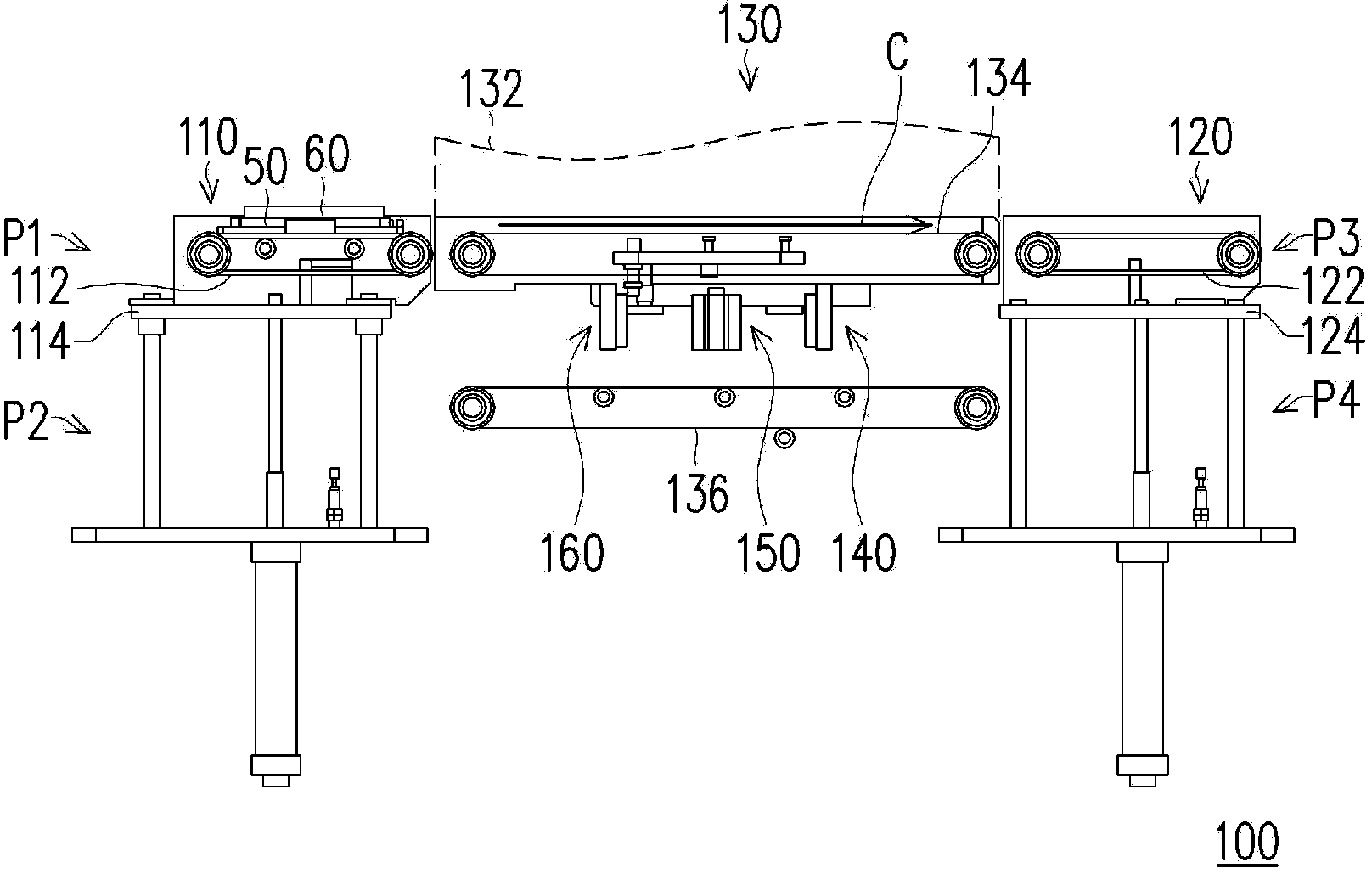

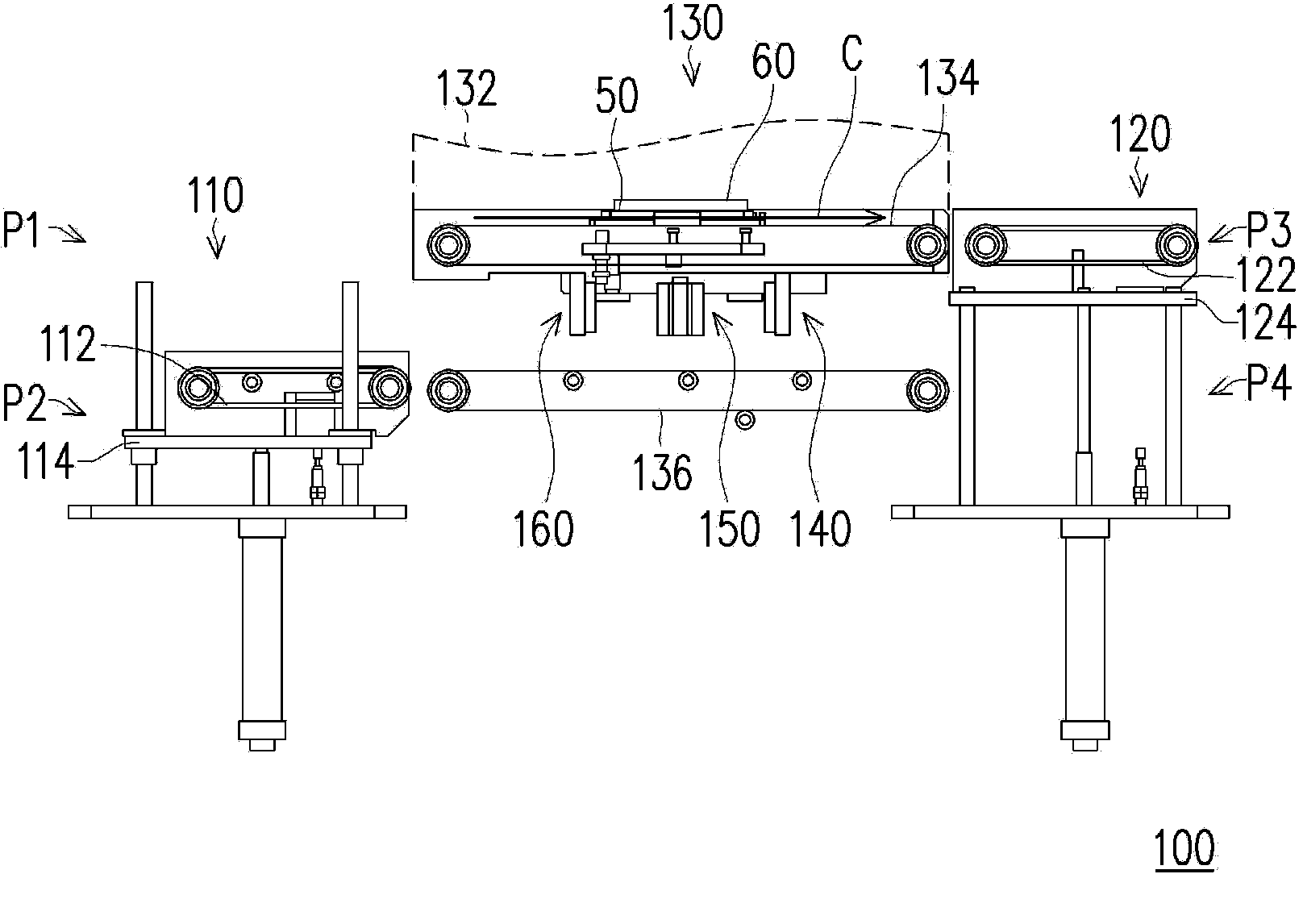

[0034] figure 1 It is a perspective view of a processing system according to an embodiment of the present invention. figure 2 for figure 1 Schematic diagram of some components of the processing system. Please refer to figure 1 and figure 2 , the processing system 100 of this embodiment includes a first conveying device 110, a second conveying device 120 and at least one processing device 130 (shown as one), wherein the processing device 130 is arranged on the first conveying device 110 and a second The conveying devices 120 are respectively adjacent to the first conveying device 110 and a second conveying device 120 . The first conveying device 110 has a first conveying unit 112 and a first lifting unit 114, and the first lifting unit 114 is used to drive the first conveying unit 112 to lift between a first position P1 and a second position P2 ( figure 2 It is shown that the first delivery unit 112 is located at the first position P1). The second conveying device 120 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com