Embedding tool for stator winding in micro permanent magnet generator

A permanent magnet generator and inner stator technology, which is applied in the manufacture of motor generators, electromechanical devices, electric components, etc., can solve the problems that the windings cannot be evenly and tightly embedded, the embedded quality cannot be guaranteed, and the production cost is high. Avoiding personal safety risks, less fatigue, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

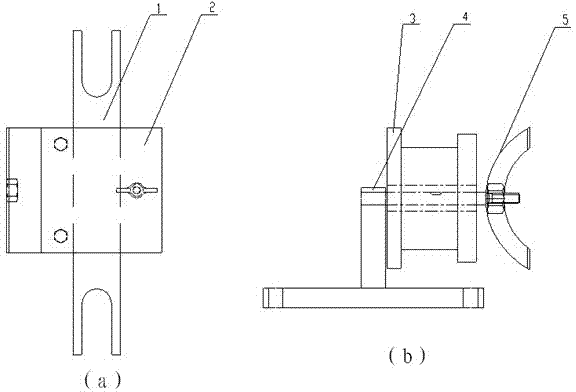

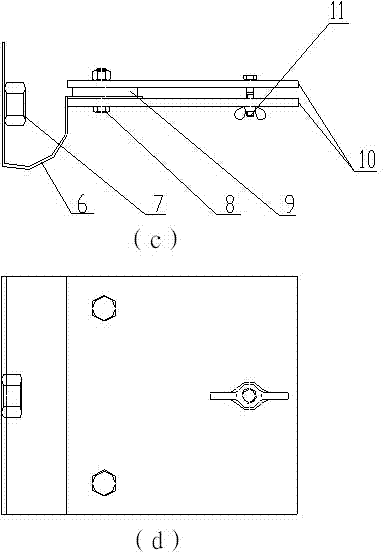

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the present invention works and implements in this way, a stator winding embedding tool in a miniature permanent magnet generator, which consists of an I-shaped winding plate 1, a combined clamp 2, a combined spacer 3, and a fixed base with a shaft 4 It is composed of a movable handle 5; the bent plate 6 of the combination fixture 2 is welded with a nut 7, which is screwed on the rotating shaft of the foot-operated winding machine. 6 connections. There is a butterfly nut 11 at the other end of the upper and lower splints 10, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com