Novel spring mattress manufacture method

A manufacturing method and mattress technology, applied to spring mattresses, mattresses, stuffed mattresses, etc., can solve problems such as easy breakage of support springs, poor user feeling, and weak comfort, so as to ensure stability, Enhanced comfort, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

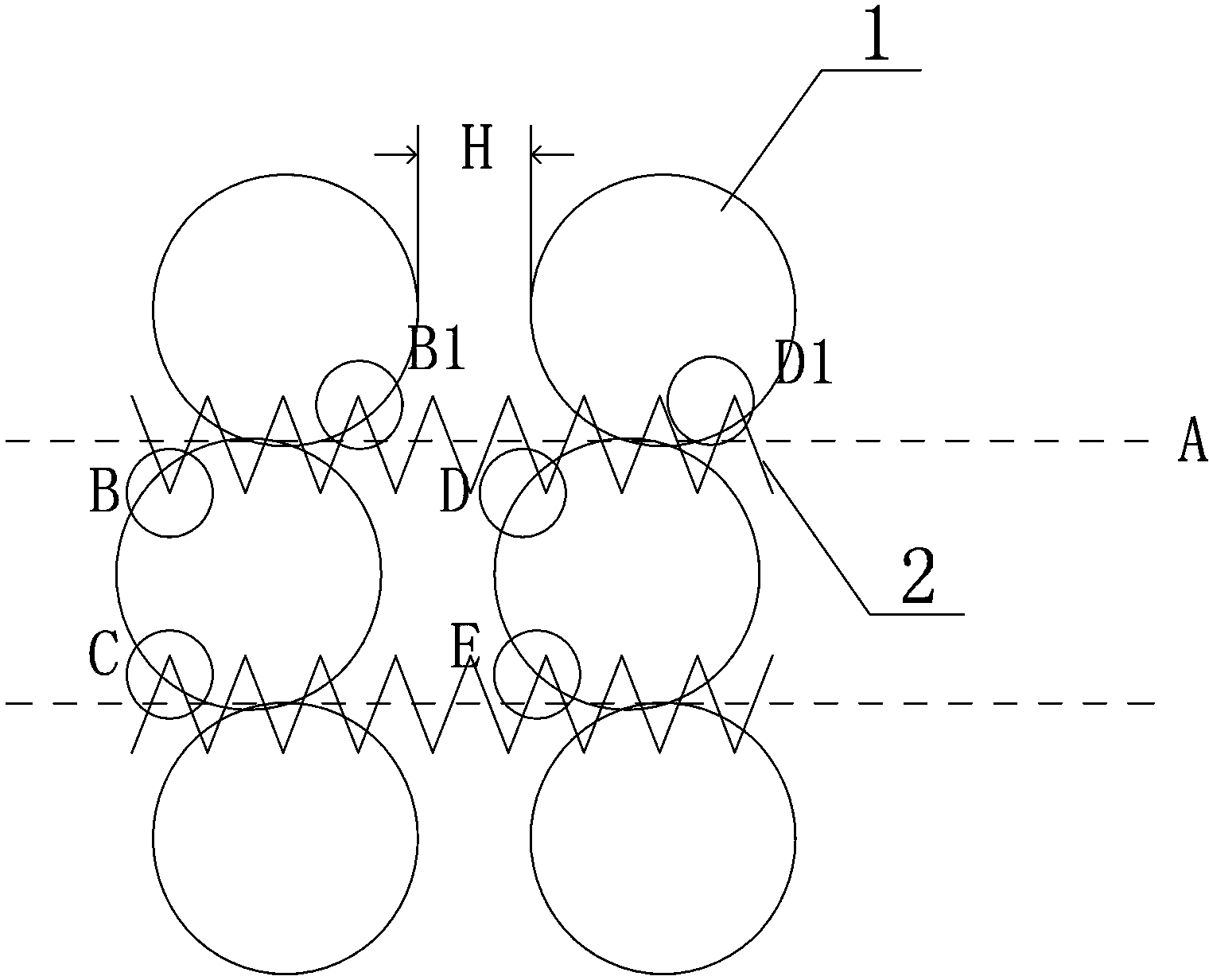

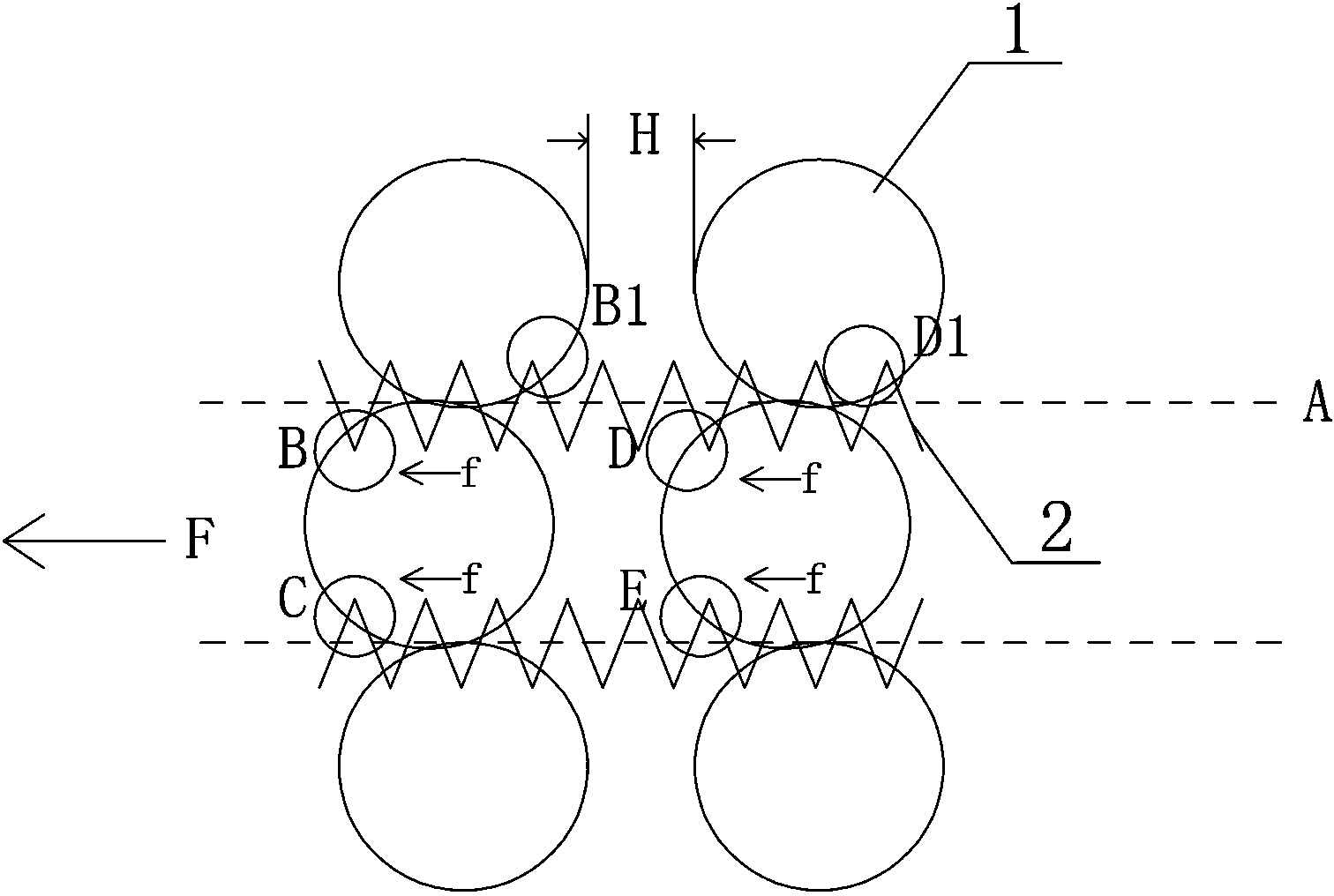

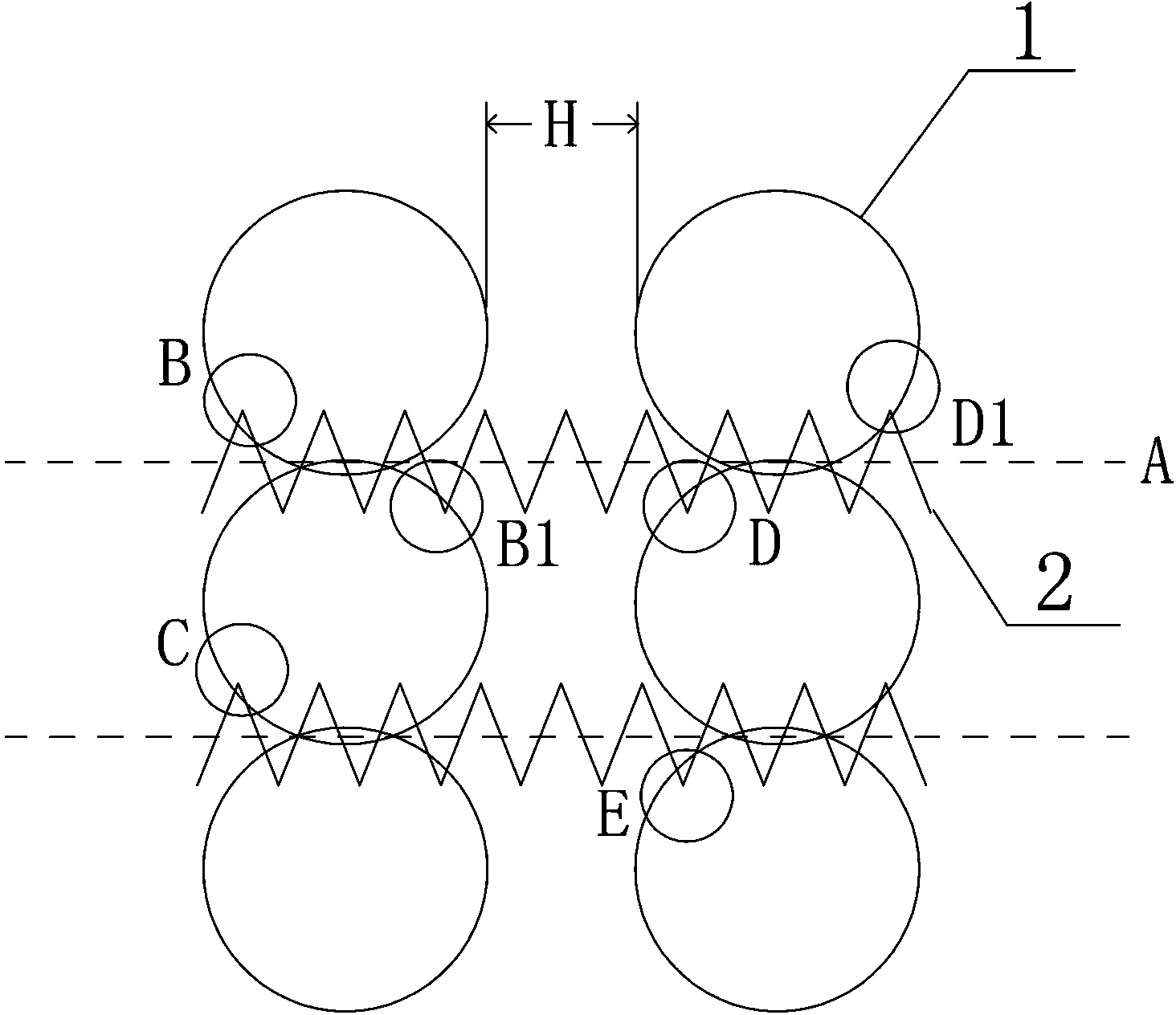

[0023] A new type of spring mattress production method, the main equipment is a spring threading machine, such as image 3 , Figure 4 and Figure 5 As shown, the steps are as follows:

[0024] (1) Arranging the concave springs: Arrange the concave springs on the workbench of the spring threading machine to form a rectangular array in horizontal rows and vertical rows, and the distance between adjacent concave springs in the horizontal row is H; The upper and lower support rings of the concave springs 1 in two adjacent rows are close to each other or cross;

[0025] (2) String springs: use a spring threading machine to insert the threaded springs 2 horizontally into the upper support rings of the concave springs 1 that are close to each other or cross each other, so that two adjacent rows of concave springs are connected to each other; in the spring stringing process In the two upper support rings adjacent in the longitudinal direction, the penetration contact part B and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Free height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap