Copper bar straightening machine of commutator

A straightening machine and commutator technology, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve problems such as broken copper bars, unsmooth feeding of high-speed punching machines, and insufficient straightness of copper bars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

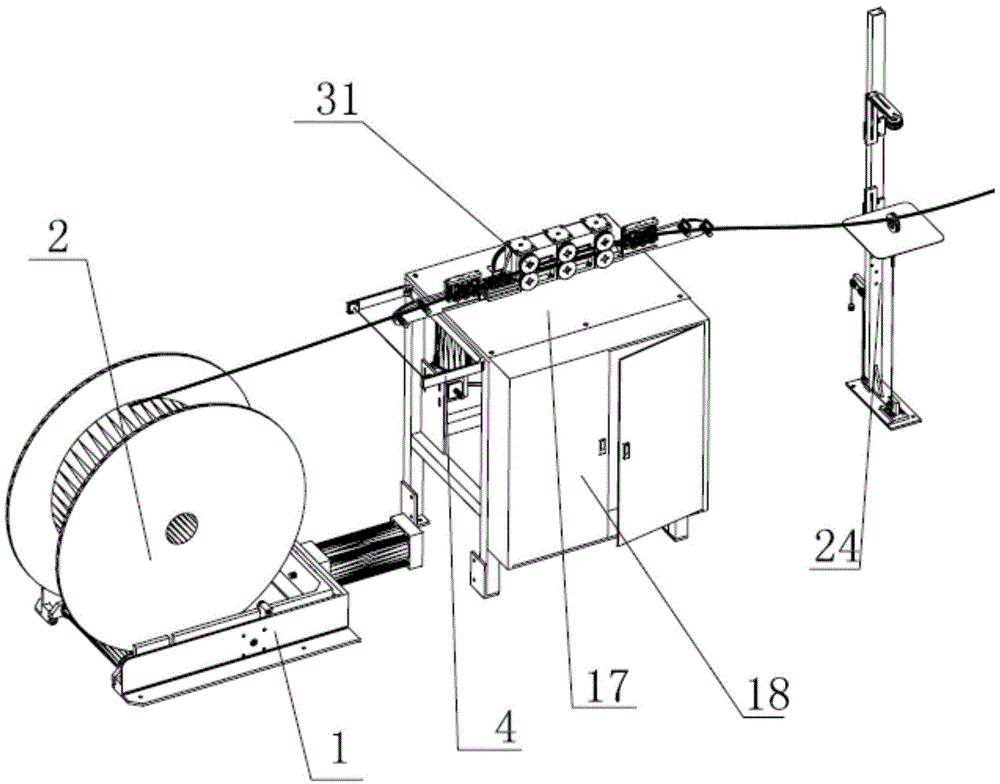

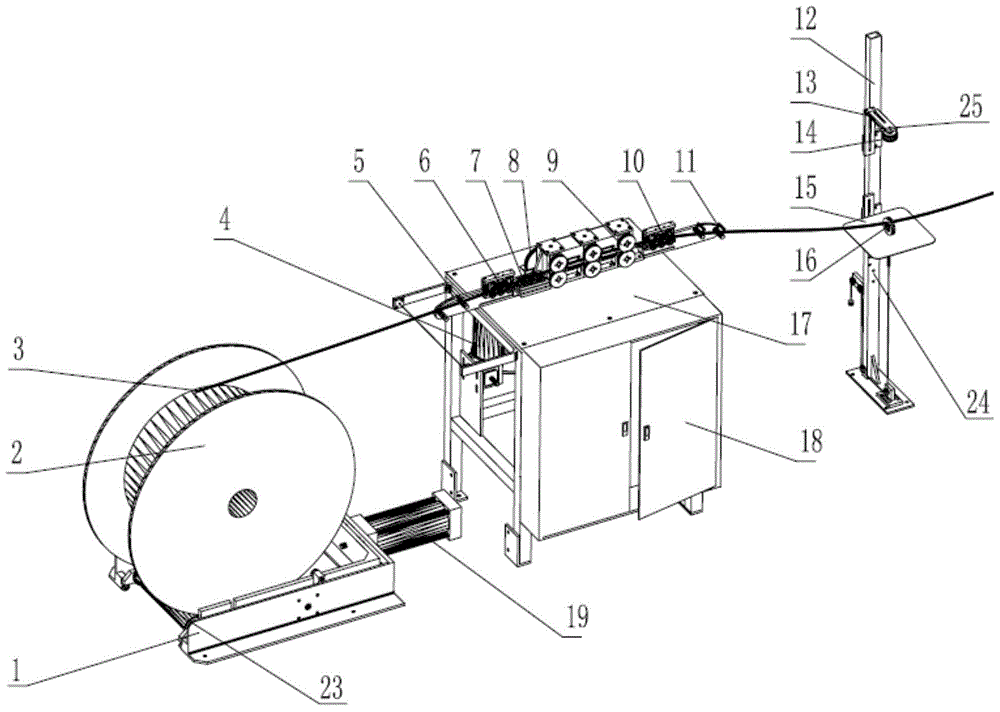

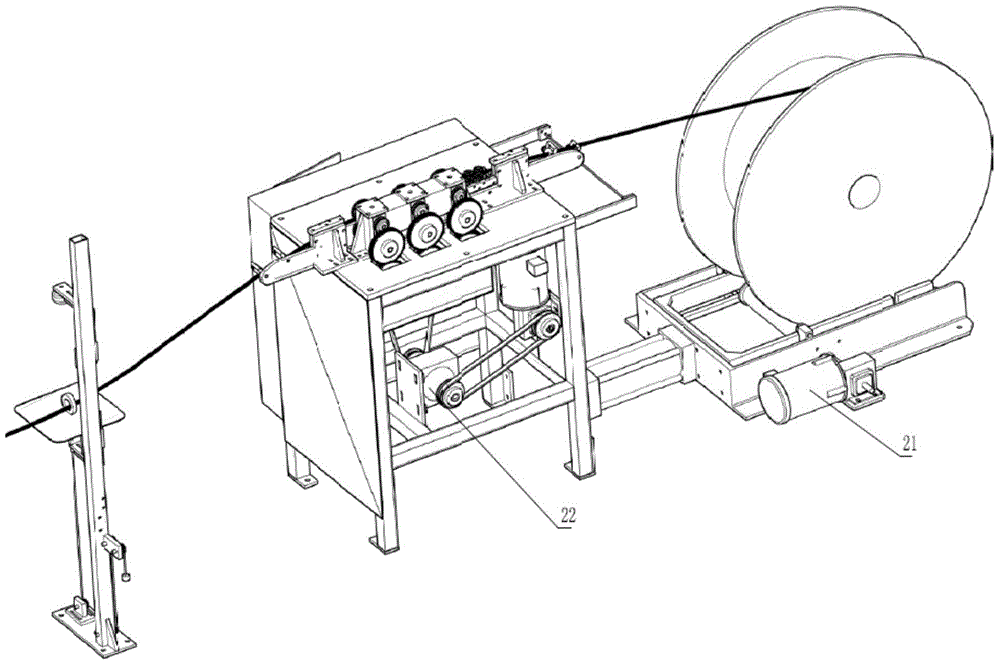

[0033] First open the pay-off reel feeding cylinder 19 on the pay-off reel frame 1, so that the pay-off reel 2 is installed on the rotating shaft 23 of the pay-off reel frame 1, then turn on the power supply, and simultaneously turn on the copper row of the pay-off reel 2 One end of 3 walks around the guide wheel 51 of the guide bracket 5 before straightening, then inserts one end of the copper bar 3 into the vertical straightening wheel A6, turns on the straightening drive motor 4, and simultaneously the pay-off motor 21 also rotates synchronously, so that the copper bar 3 After passing through the vertical straightening wheel A6, the horizontal straightening wheel 7, the straightening traction wheel 9, the vertical straightening wheel B10 and the straightening rear guide bracket 11 in turn, and passing through the middle part of the ultrasonic detection plate 15, a copper bar guide ring 16 is installed, and then The copper bar 3 is installed in the feeding mechanism of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com