Rotary welding workbench

A technology of rotating workbench and workbench, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low welding efficiency and low equipment utilization rate, and achieve improved welding efficiency and equipment utilization rate , Guarantee the effect of welding consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

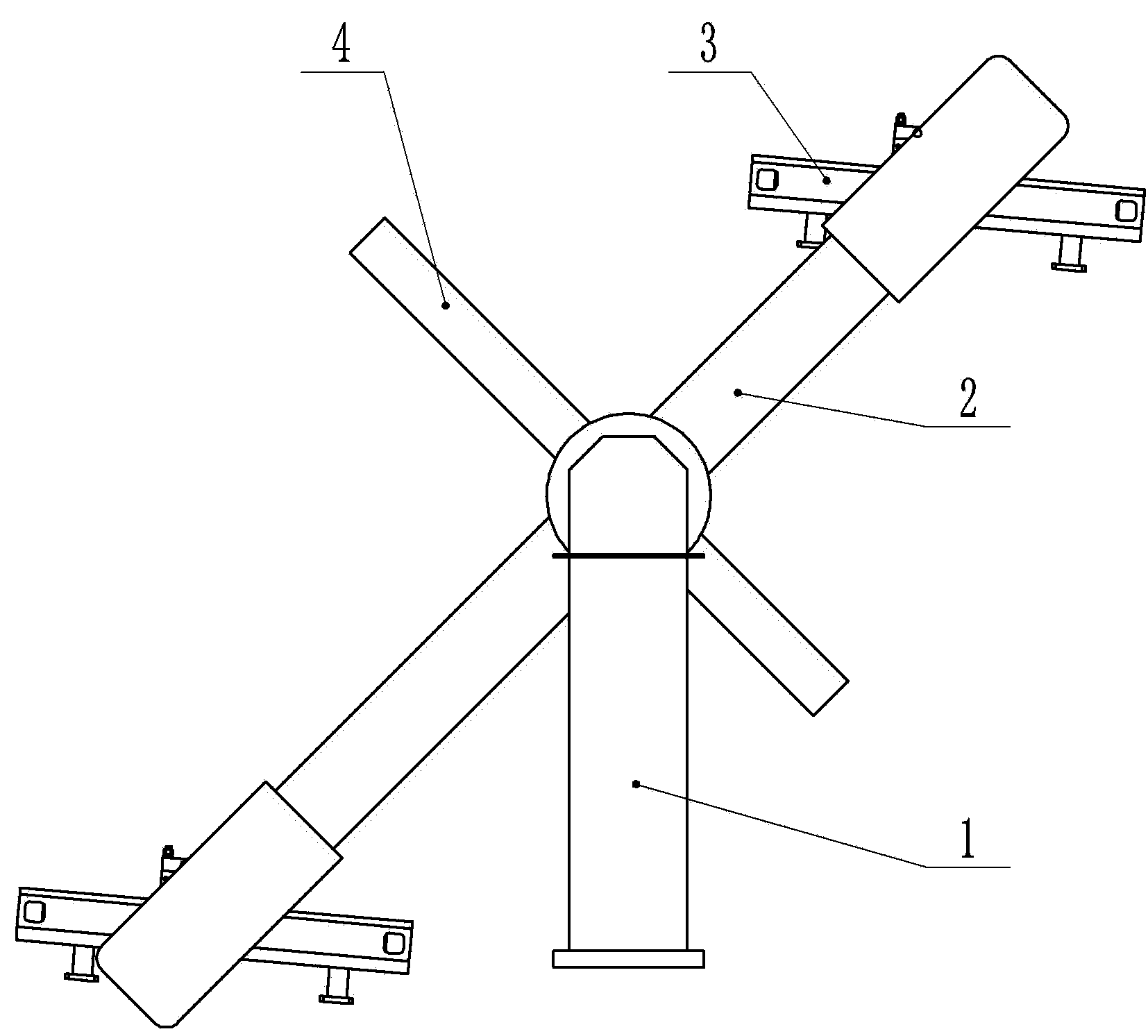

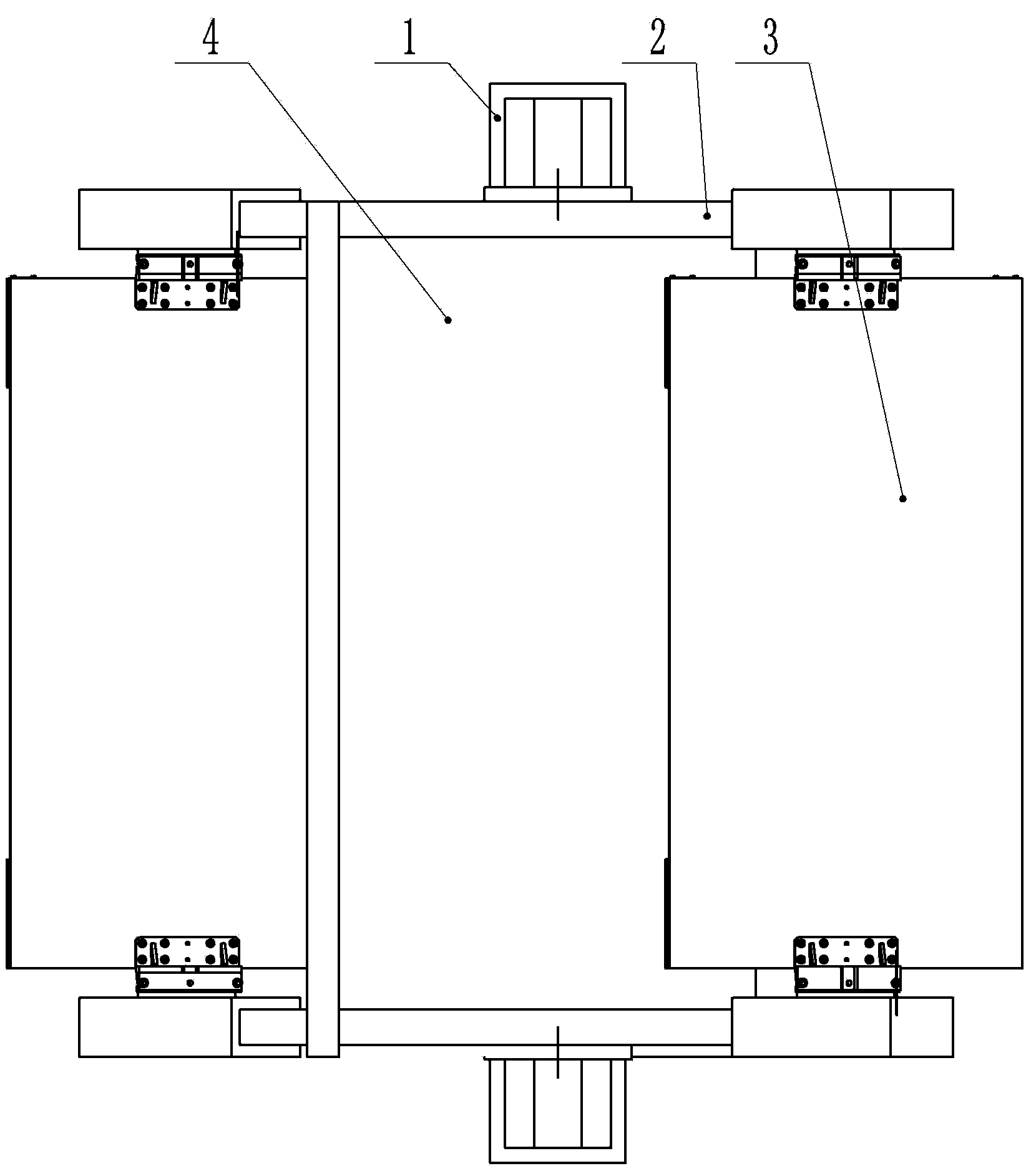

[0012] figure 1 and figure 2 The welding rotary table shown mainly includes a supporting frame, a rotary driving device, a rotating arm 2, a welding table 3, and a protective plate 4. The supporting frame includes two opposite columns 1, and the rotary driving device is installed in one of the columns 1. , the rotary driving device of this embodiment is a reducer controlled by a controller, the controller and the reducer are electrically connected through a control switch, and shafts are arranged opposite to each other at the same height positions of the two columns 1, and each column 1 is The rotating arm 2 that rotates around the corresponding axis is hinged, the rotating drive device is installed on the column 1, the output shaft of the reducer is connected to the rotating arm 2, and a welding workbench is respectively installed between the two rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com