A fully automatic soft bottle packing machine and its packing method

A bottle cartoning machine, fully automatic technology, applied in packaging, bottle packaging, transportation and packaging, etc., can solve the problems of increased production cost, poor use effect, security, etc., to ensure complete transportation, improve work efficiency, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

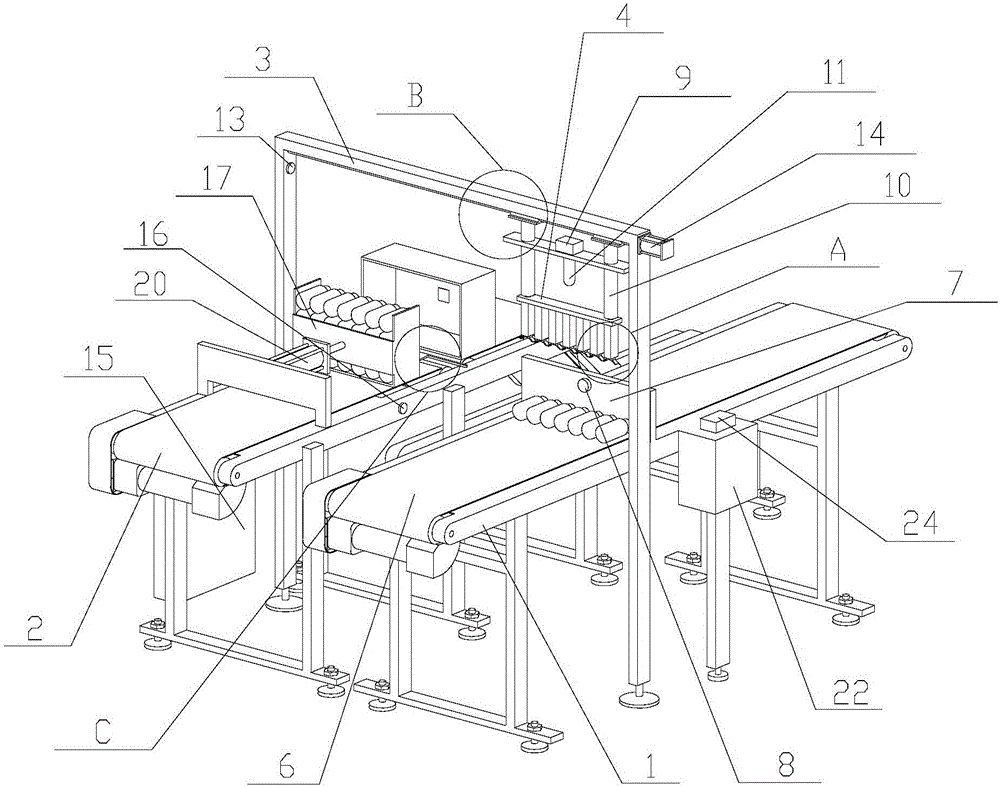

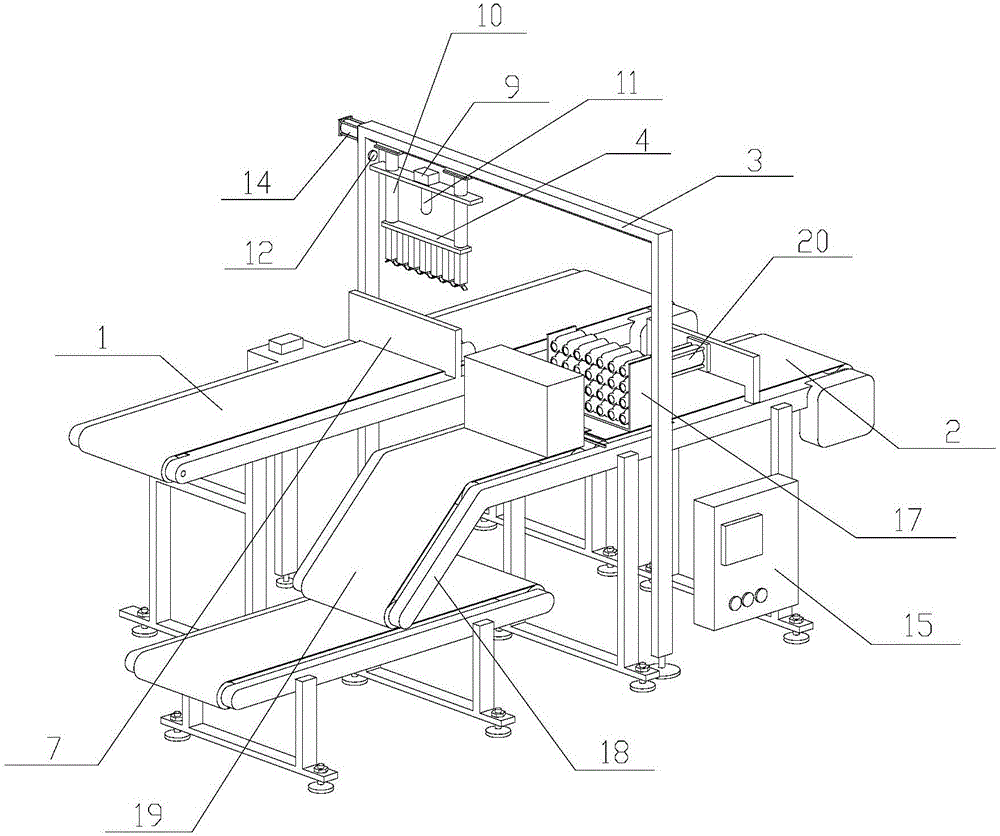

[0019] The present invention will be further described below in conjunction with accompanying drawing:

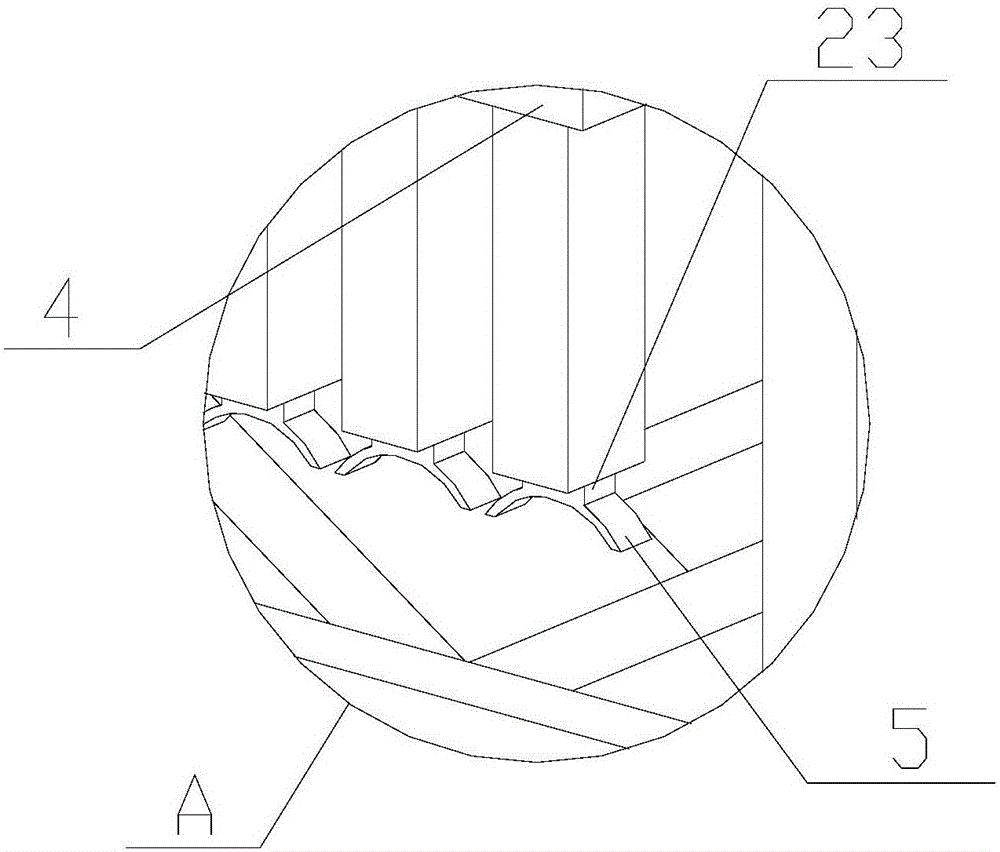

[0020] With reference to accompanying drawing: this full-automatic soft bottle cartoning machine comprises a conveying frame 1, and one side of conveying frame 1 is connected with frame 2, and is connected between conveying frame 1 and frame 2 and spans between conveying frame 1, machine The frame 3 above the frame 2 is connected with a hanging rod 4 that can move on the frame 3 on the frame 3, and a group of suction cups 5 are connected on the bottom surface of the hanging rod 4, and the push plate 17 positioned at the frame 3 below is installed on the frame 2.

[0021] The suction cup 5 adopts a vacuum suction cup, the conveying frame 1 is used to transport the labeled soft bottles, the frame 2 is used for packing the soft bottles, and the two ends of the frame 3 are respectively connected to the outside of the conveying frame 1 and the outside of the frame 2 to horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com