A kind of material paving machine

A paving machine and intermediate material technology, which is applied in the direction of conveyor objects, transportation and packaging, loading/unloading, etc., can solve the problems of low production efficiency of manual paving, difficulty in realizing continuous paving, unstable performance of decorative panels, etc. Achieve the effect of easy installation and maintenance, compact structure, and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

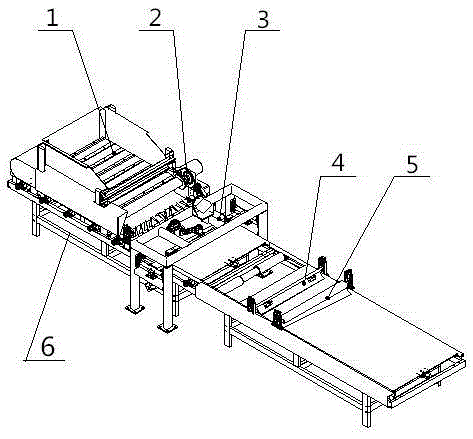

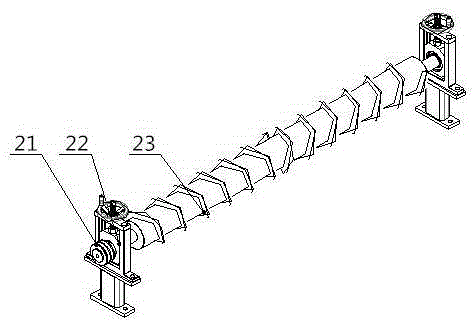

[0021] Such as figure 1 As shown, the middle material paving machine includes a frame 6 and a material spreading mechanism arranged on the frame 6, a material spreading template is provided between the frame 6 and the material spreading mechanism, and the material spreading mechanism includes scrapers connected in sequence 1. Spiral equalizing mechanism 2, vibrating scraper 3, pneumatic scraper mechanism 4 and inclined scraper mechanism 5.

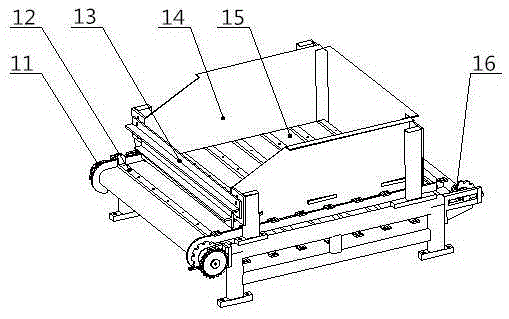

[0022] Such as figure 2 As shown, the scraper machine 1 includes a shaft transmission mechanism 11, a rotating scraper 12, a front-end height limiting plate 13, a material retaining plate 14, a material platform 15 and a belt tensioning mechanism 16. In order to prevent the material baffle plate 14 from spilling, a front end height limiting plate 13 is provided at the discharge end of the material baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com