Light expansion shaft

A shaft-expanding, light-weight technology, which is applied in the field of expanding shafts for tightening the central reel of film-like materials, can solve the problems of requiring at least two employees, the pitch of the screw should not be too large, and the coaxiality is not easy to control, so as to achieve simple structure, Reduce the rotational inertia and solve the effect of excessive deviation of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

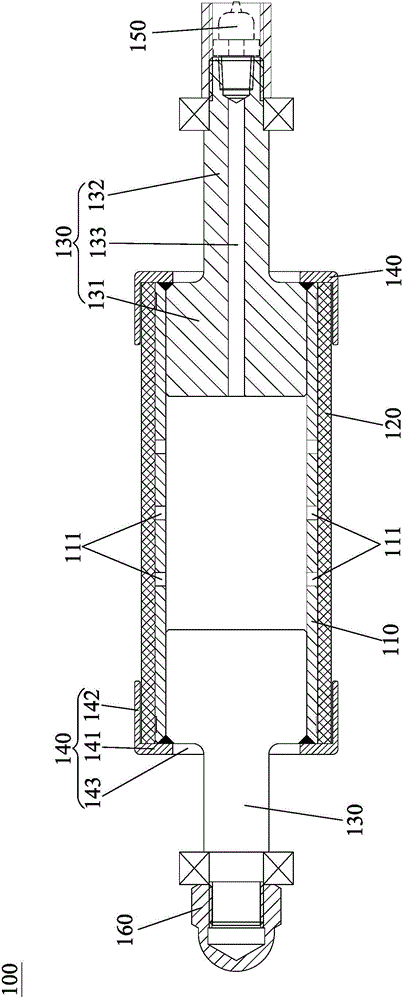

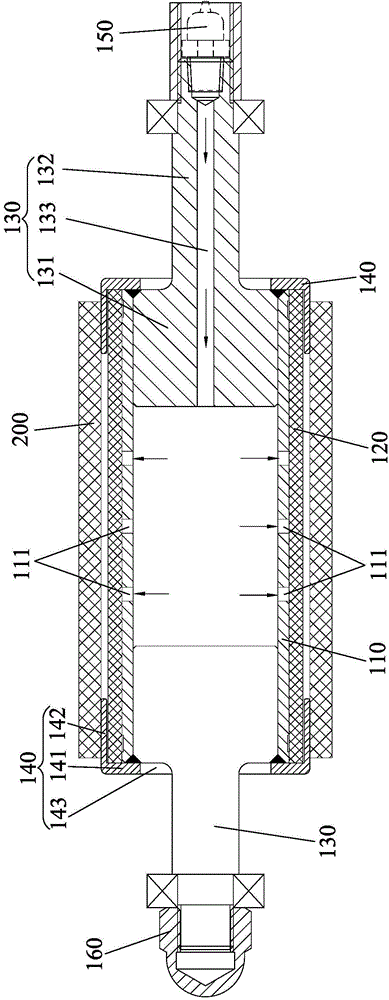

[0019] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. The light-duty expansion shaft 100 provided by the present invention is suitable for winding and unwinding equipment for film-like materials, and is used for winding and unwinding the film-like materials.

[0020] Such as figure 1 , figure 2 As shown, the lightweight expansion shaft 100 provided by the present invention includes a support tube 110 and an expansion tube 120 sheathed outside the support tube 110, and the two ends of the expansion tube 120 are sealed and fixed to the support tube 110, The support tube 110 has a hollow structure and is sealed at both ends. The side wall of the support tube 110 is penetratingly provided with a vent hole 111 communicating with the hollow structure. The air intake hole 133. When in use, the central reel 200 of the film-like material is sleeved outside the expansion tube 120, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com