Self-clamping lifting device for underwater rotating body

A hoisting device and self-clamping technology, used in transportation and packaging, load hoisting components, etc., can solve hidden safety hazards, increase the difficulty of hoisting work, cumbersome and other problems, and achieve improved operational safety, convenient hoisting, reduced strength and effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

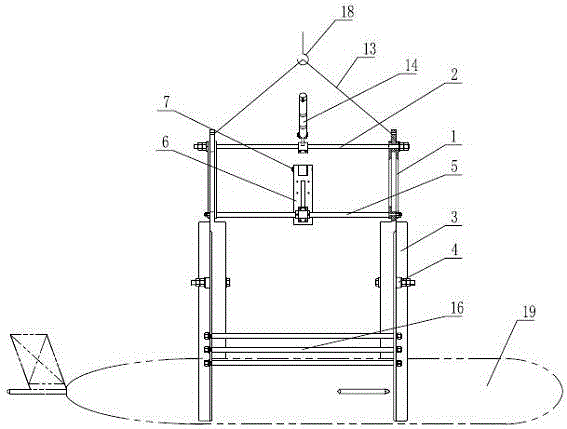

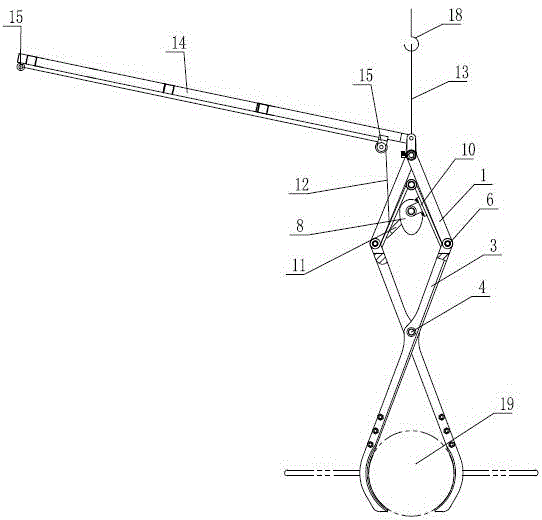

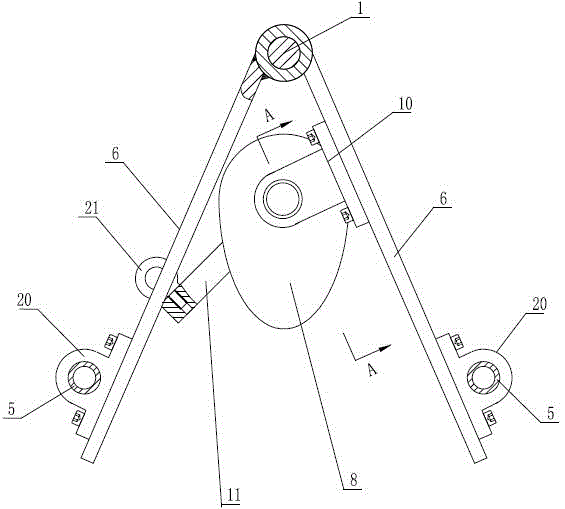

[0020] See figure 1 , figure 2 , the present invention includes two sets of unclamping mechanisms arranged in parallel along the axial direction of the steering rod 2, the unclamping mechanism includes two suspension rods 1, the upper ends of the two suspension rods 1 are axially limited and installed on the same steering rod 2 Specifically, the two suspension rods 1 are axially limited on the rod section formed by the shoulder of the steering rod 2 and the nut assembly on the steering rod 2. When the clamping operation is performed, the two suspension rods 1 can rotate around the steering rod 2. In the clamp release mechanism, the lower ends of the two suspenders 1 are respectively connected to a splint 3, and the two splints 3 are arranged crosswise. The upper end of the 3 and the lower end of the connected suspender 1 are locked on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com