Double-sided wool fabric material slitting machine with full-automatic grinding knife and control method thereof

A technology of double-sided woolen and split sewing machine, which is applied in the direction of double-sided fleece fabric cutting, which can solve the problems of long time consumption, achieve low noise, improve work efficiency, and reduce equipment investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

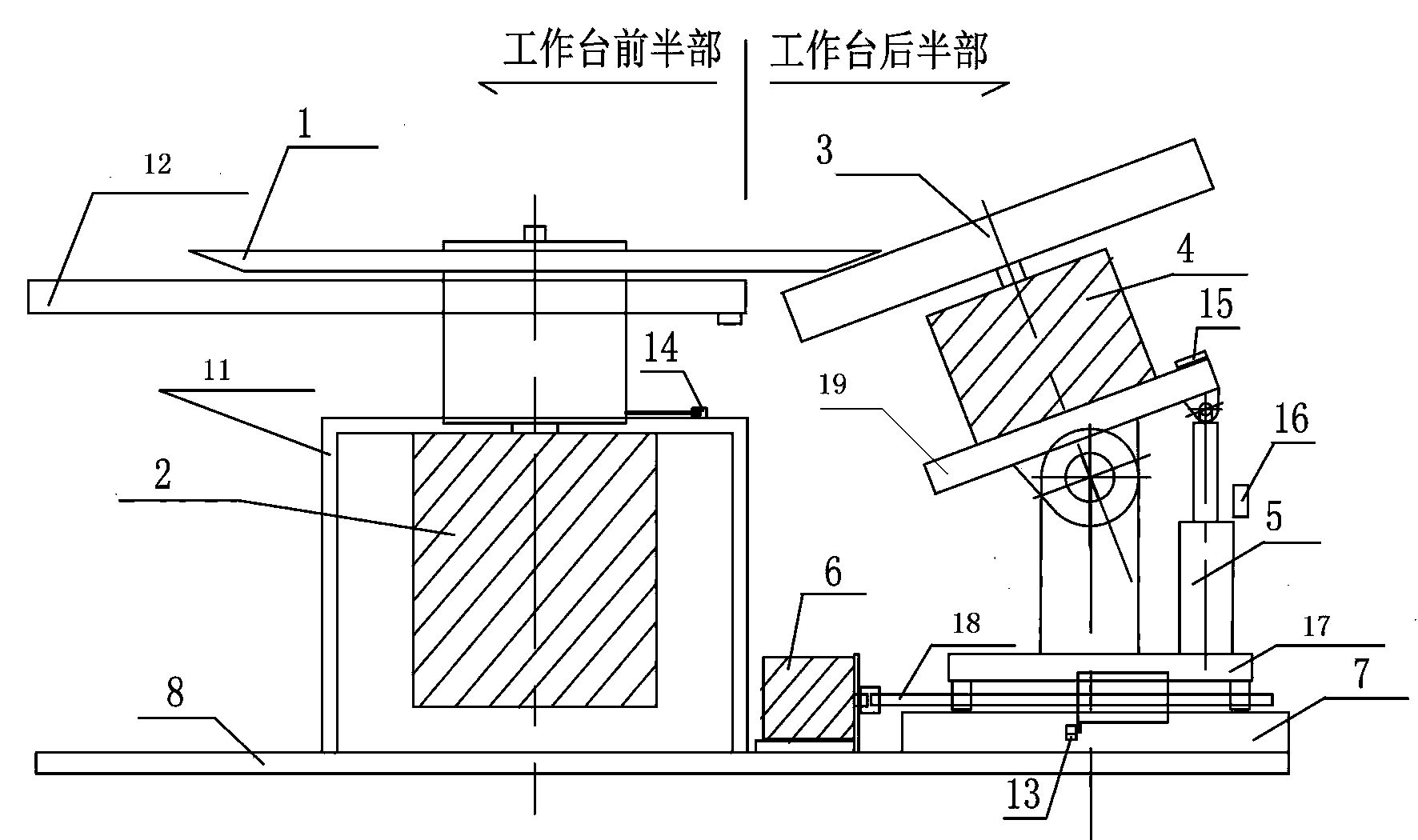

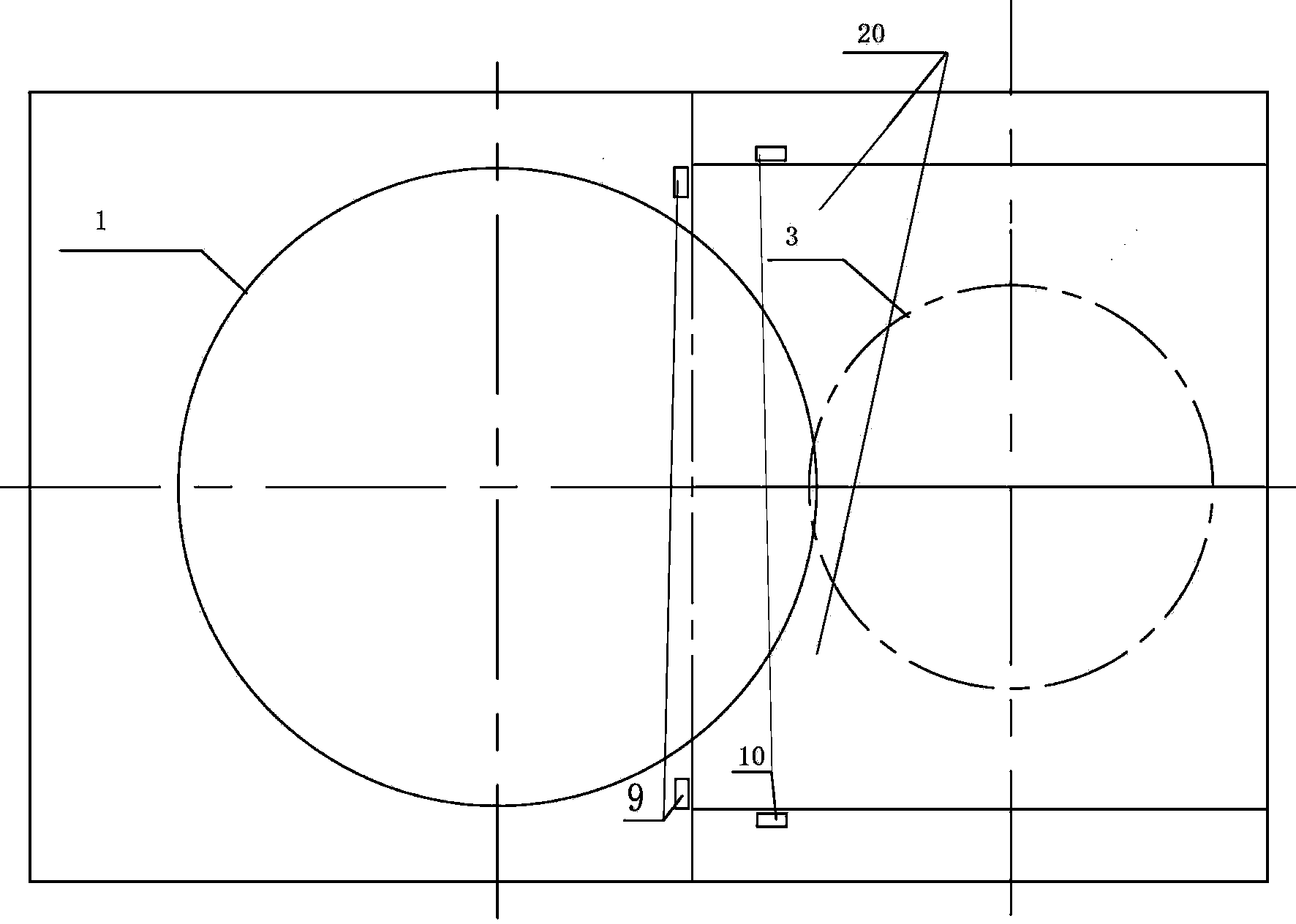

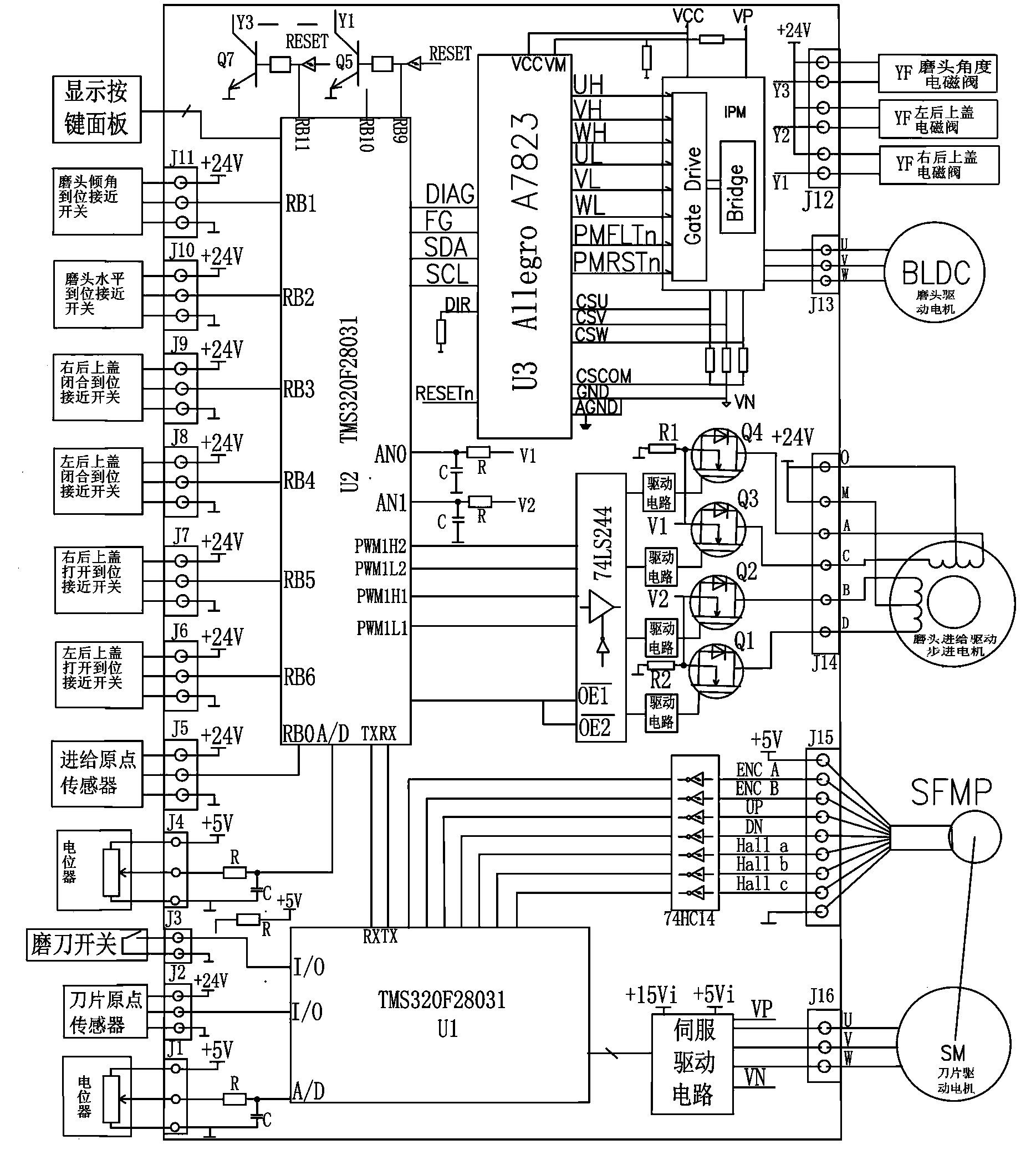

[0024] refer to figure 1 , 2 , 3, 4, 5, a double-sided sewing machine with fully automatic knife sharpening, including a base platform 8, a motor support 11 is provided on the base platform 8, a blade drive motor 2 is housed in the motor support 11, and the blade drives Blade 1 is housed on the output shaft of motor 2, and front loam cake 12 and rear loam cake 20 are housed in double-sided sewing machine, and on one side of motor support 11, the rear half of base platform 8 is equipped with grinding head mechanism; Mechanism comprises two guide rails 7 that are fixed on the base platform, and guide rail platform 17 is housed on two guide rails 7, and described guide rail platform 17 is connected with grinding head feeding drive stepper motor 6 by nut and screw mandrel 18, and described guide rail platform Grinding head angle cylinder 5 and rotatable platform 19 are housed on it, and grinding head driving motor 4 is fixed on the rotatable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com