Bridge cast-in-cantilever method cradle counter-pressure construction method

A construction method and technology for bridges, which are applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of difficult to meet the needs of large-span variable-section continuous box girder and rigid-frame bridges, and it is difficult to accurately simulate hanging basket pouring. Work status, limited work space and other problems, to achieve the effect of simple structure, easy control and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

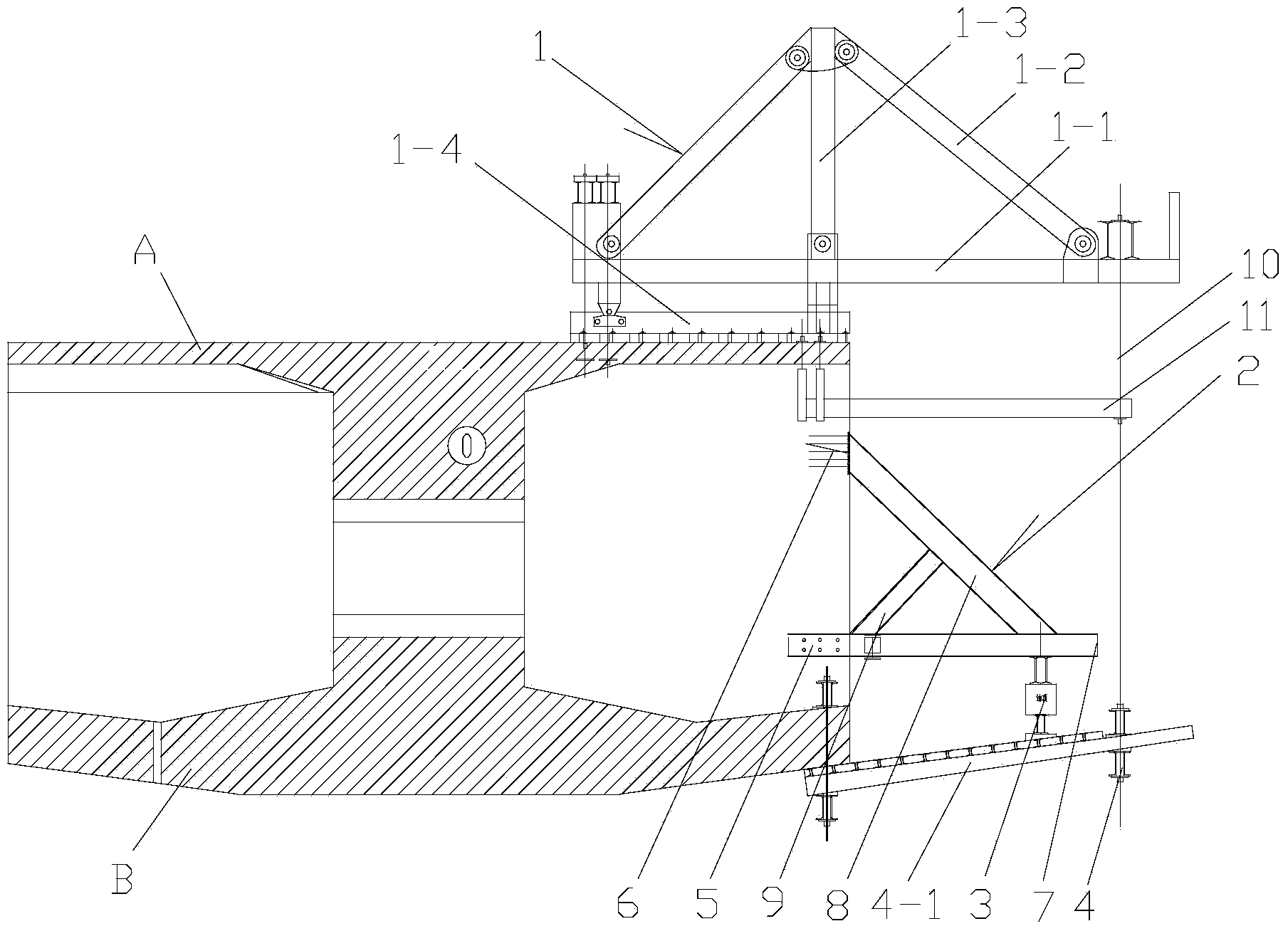

[0022] For the construction method of bridge suspended pouring and hanging basket back pressure construction method in this embodiment, please refer to figure 1 , the hanging basket is at the front ends of the two cantilevers of the T structure (only one end is shown in the figure). In order to ensure the balanced stress at both ends of the T structure, the loading of the two hanging baskets at both ends of the cantilever should be basically synchronized to reduce its unbalanced bending moment. The method comprises the following steps during concrete implementation:

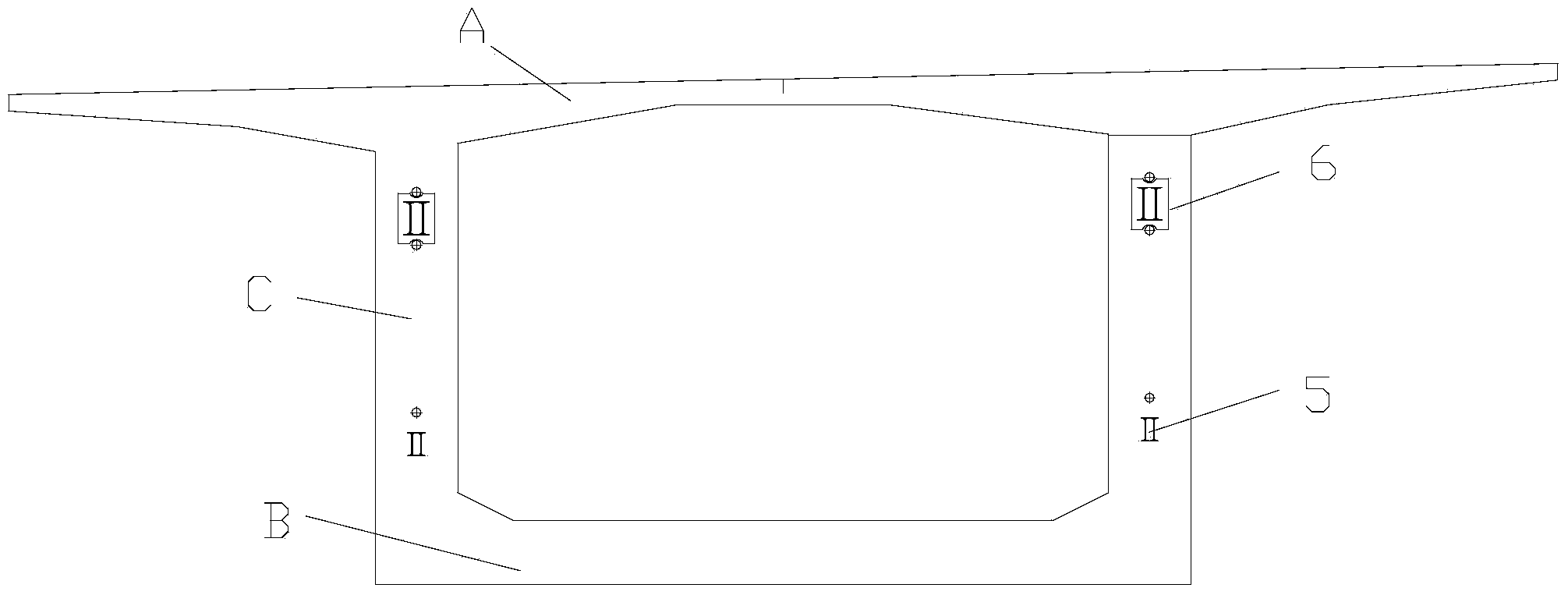

[0023] The first step is to construct the foundation section of the bridge—construct the foundation section of the bridge according to the predetermined design, and its longitudinal section in the longitudinal direction is as follows: figure 1 As shown, the top beam plate A and the bottom beam plate B are connected by a beam pier with a manhole, and the whole is in the shape of an "I", and its end face is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com