Motor grader cross slope control with articulation compensation

A laterally inclined, grader technology, used in mechanically driven excavators/dredgers, earthmovers/shovels, construction, etc. Erosion path, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

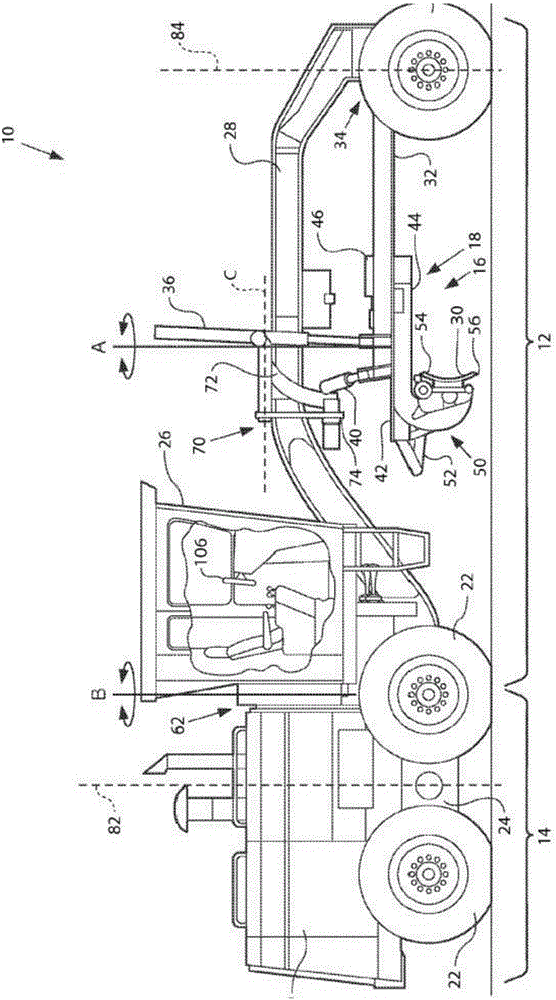

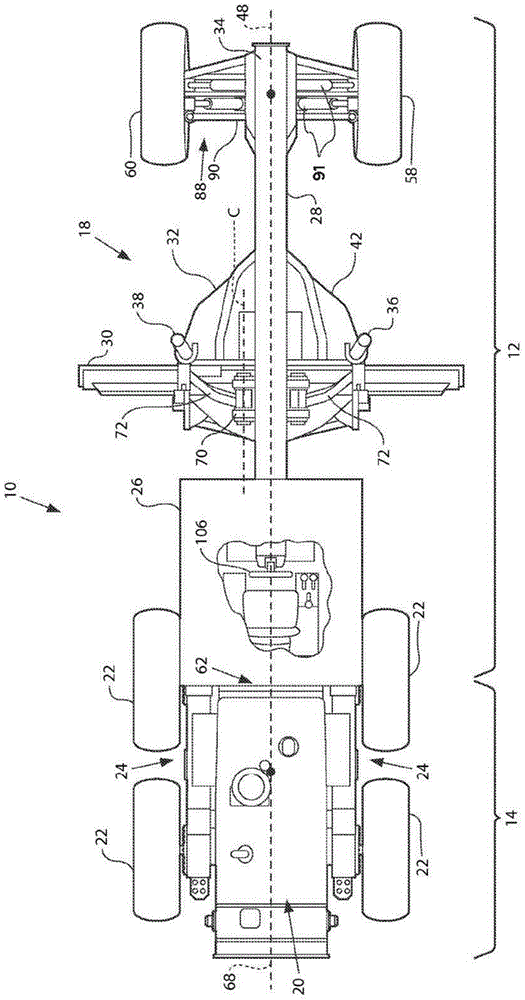

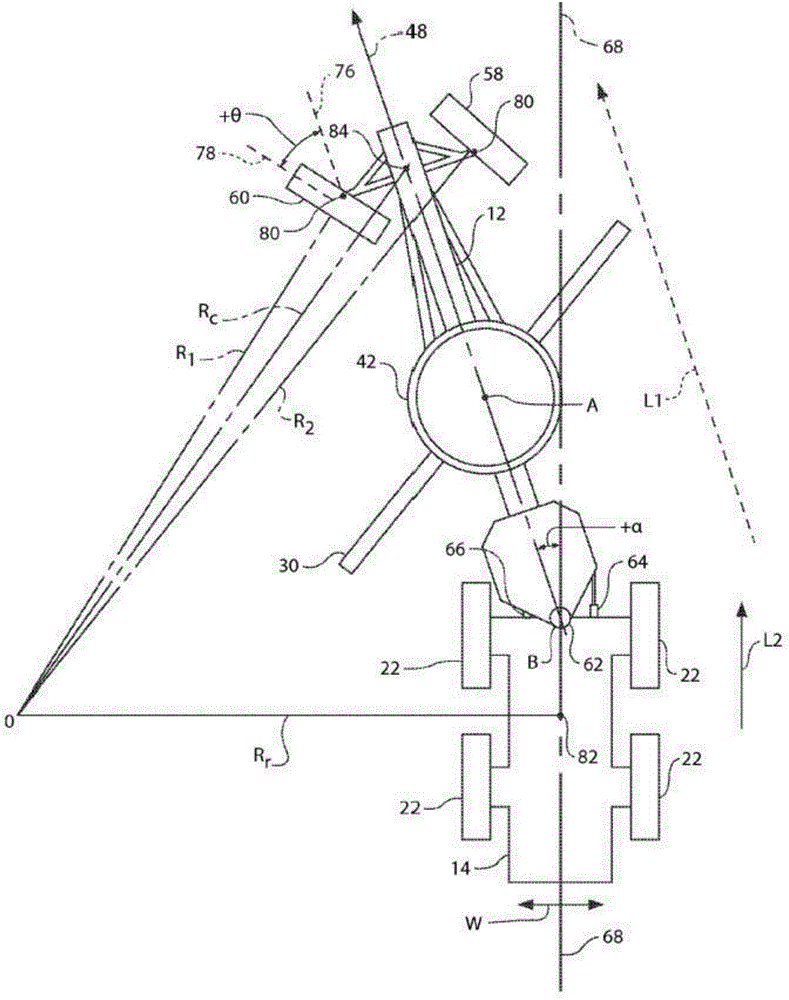

[0019] The present invention provides a system and method for motor grader blade control for compensating for machine pitch, roll, steering, and articulation to replicate desired laterally inclined cutting angles in the ground being prepared. In particular, the blade lateral tilt angle is adjusted according to a pure tracking method such that the actual lateral tilt cutting angle corresponds to the desired lateral tilt cutting angle. The controller receives a signal indicative of a desired lateral rake cutting angle and executes a pure tracking routine to determine the blade lateral rake angle required to give the desired lateral rake cutting angle taking into account machine pose and configuration. In short, the pure tracking procedure consists of determining the direction of blade travel and determining its horizontal component. Projecting the blade edge onto a plane perpendicular to the horizontal component of the blade travel direction and yielding a tilt function specifyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com