Decorative roof

A steel beam and unit type technology, which is applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve problems such as corrosion of decorative structural parts, affecting waterproof functions, and hidden safety accidents, achieving good waterproof performance. Improve aesthetics and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in combination with specific embodiments.

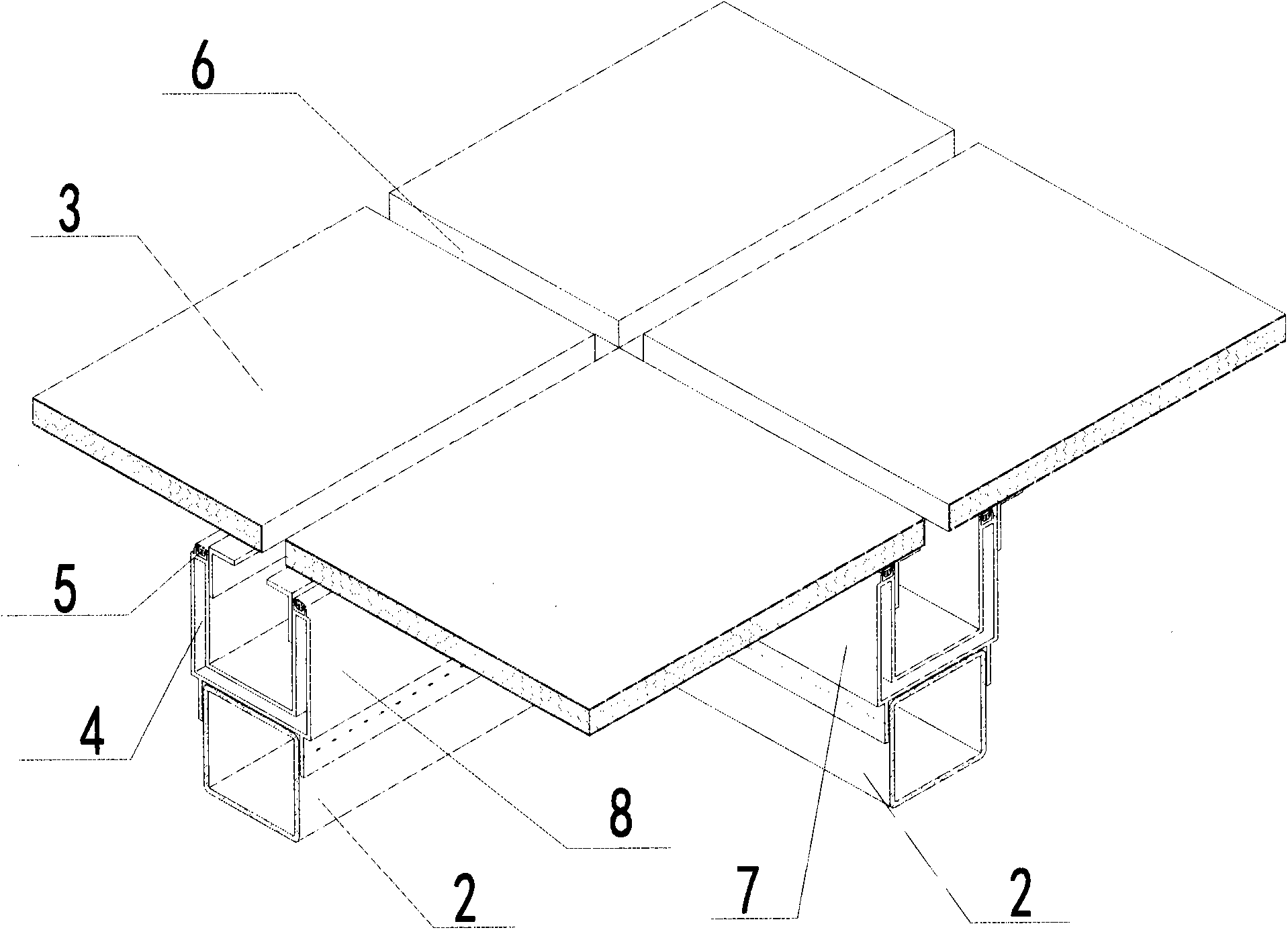

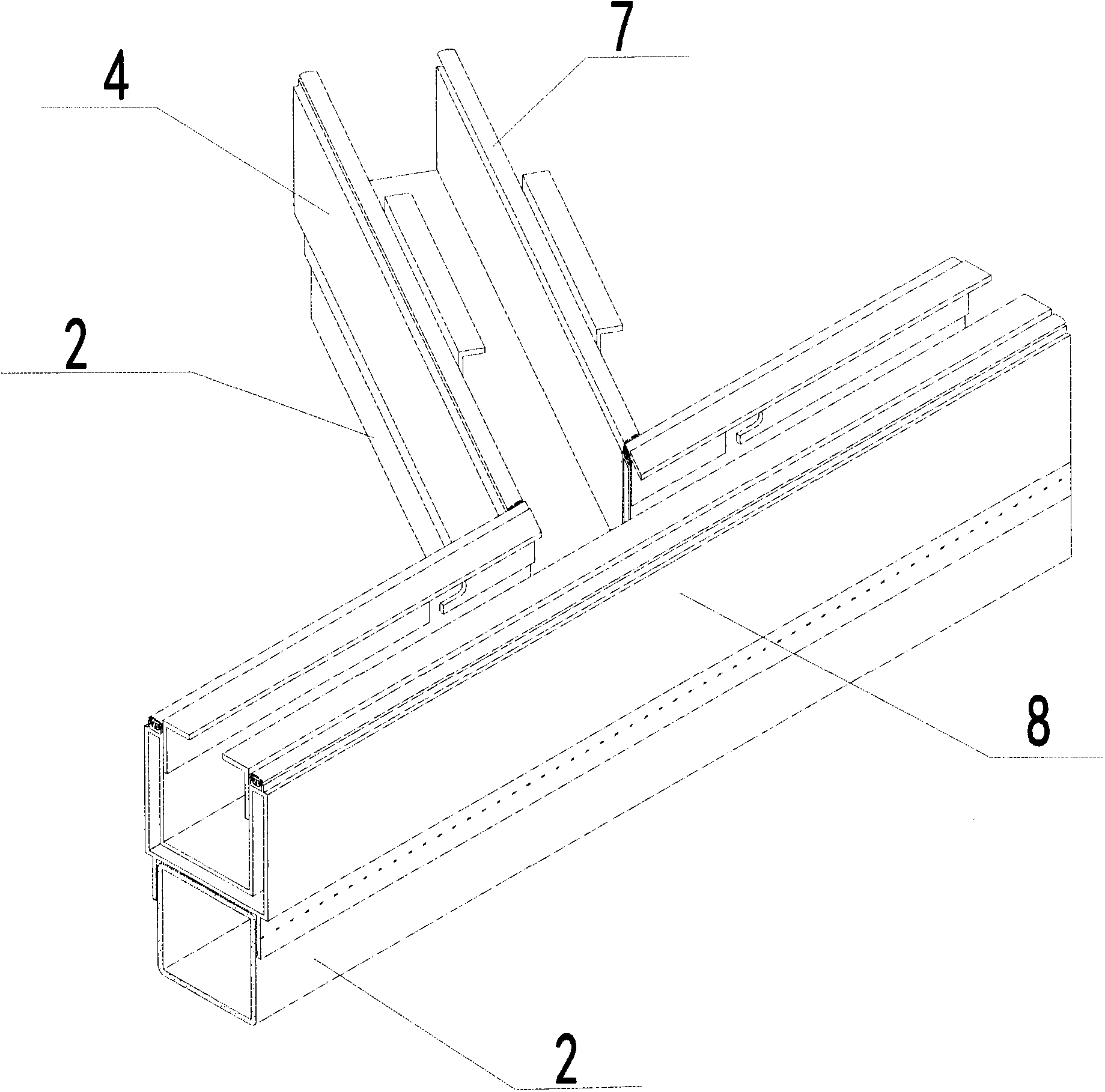

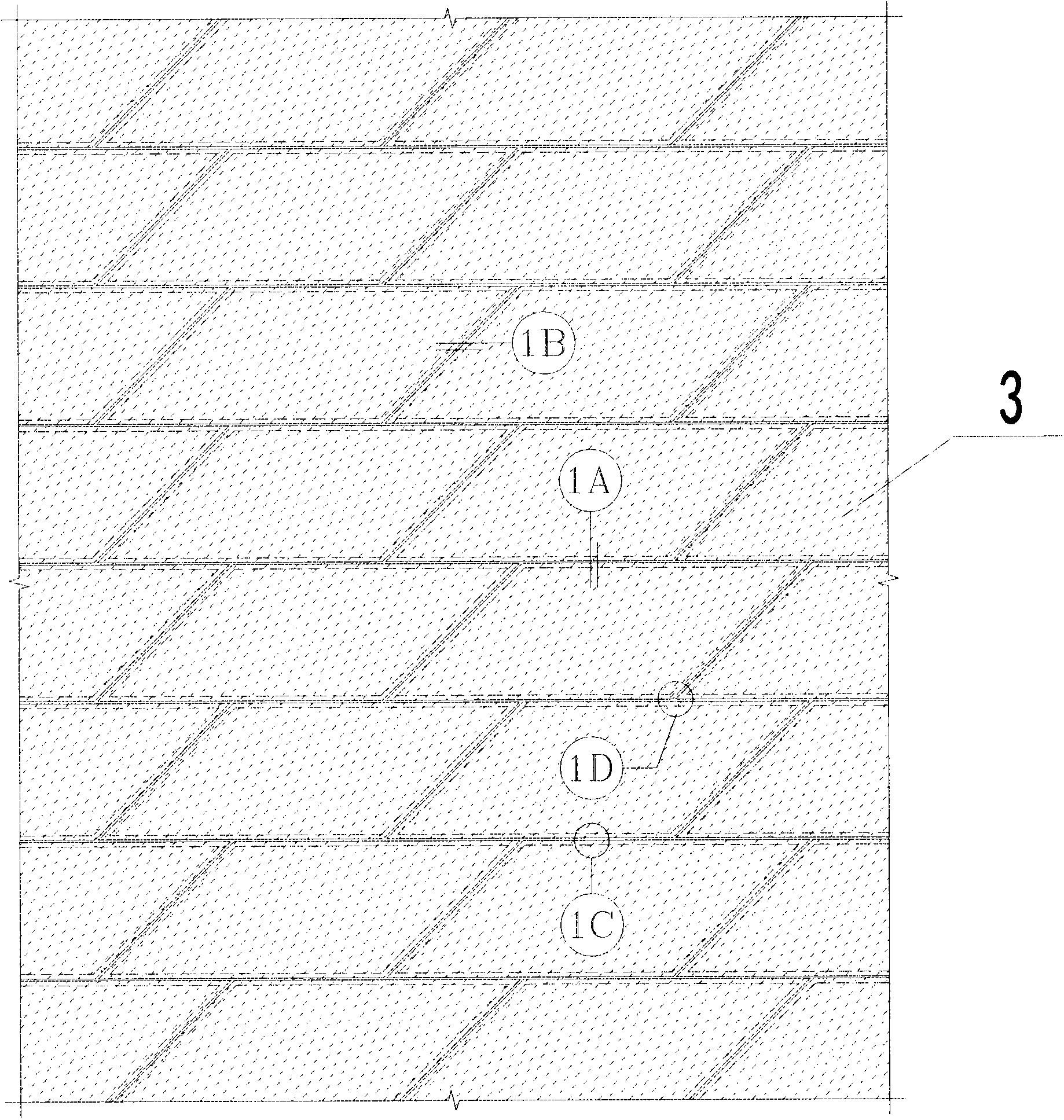

[0023] A decorative roof such as Figure 1-9 As shown, it includes several steel columns 1, several steel beams 2 and several unit energy-saving honeycomb panels 3, steel beams 2 are arranged above the steel columns 1, and the steel beams 2 are spliced with each other to form a bracket, and the upper part of the bracket is set There is a profile component 4, the profile component 4 is connected to the unit type energy-saving honeycomb panel 3 through a fastener 5, the profile component 4 is fixedly connected to the steel beam 2, and the steel beam 2 is fixedly connected to the steel column 1; the unit An open gap 6 is provided between the type energy-saving honeycomb panel 3 and the unit type energy-saving honeycomb panel 3, and the open gap 6 forms a drainage channel, and the drainage channel forms a drainage system.

[0024] The splicing angle of the steel column 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com