Efficient and low-consumption combined formwork system and construction method thereof

A technology of combining formwork and construction method, which is applied in the field preparation and construction of formwork/formwork components and building components, and can solve the problems of high construction cost, low safety performance, and slow erection speed of fastener-type steel pipe scaffolding. , to achieve the effect of reducing construction consumption and improving social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below with reference to the drawings and embodiments.

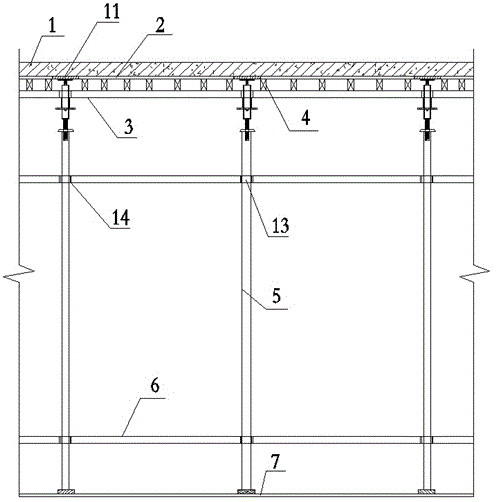

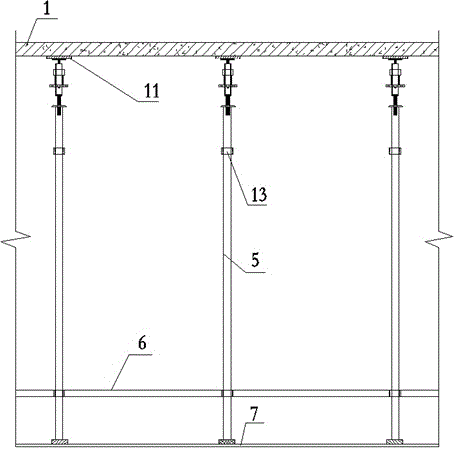

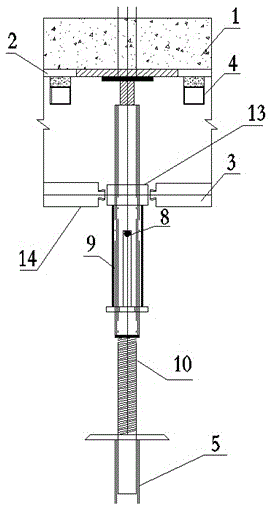

[0021] Such as figure 1 , 2 As shown, the high-efficiency and low-consumption combined formwork system of the present invention includes an early dismantling part and a non-early dismantling part. The early dismantling part includes early dismantling formwork 2, and the non-early dismantling part includes non-early dismantling formwork 11, early dismantling formwork 2 and The non-early dismantling formwork 11 is arranged alternately in rows and intervals under the concrete floor 1; the lower part of the early dismantling formwork 2 is supported on the crossbar 3 through the backing 4, and the non-early dismantling formwork 11 is supported on the vertical pole 5; The two ends of the rod 3 are supported on the vertical pole 5 and can move up and down to fix or disassemble the early demolition template 2. An early dismantling head is provided at the junction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com