Axial turbomachine stator with ailerons at the blade roots

A technology of turbines and stators, which is applied to the supporting elements of blades, stators, mechanical equipment, etc., can solve the problems of pressure drop, reduce the flow area of annular flow, etc., and achieve the effect of eliminating stall, improving performance, and improving capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following description, the terms inner or inner and outer or outer refer to a position relative to the axis of rotation of the axial turbine.

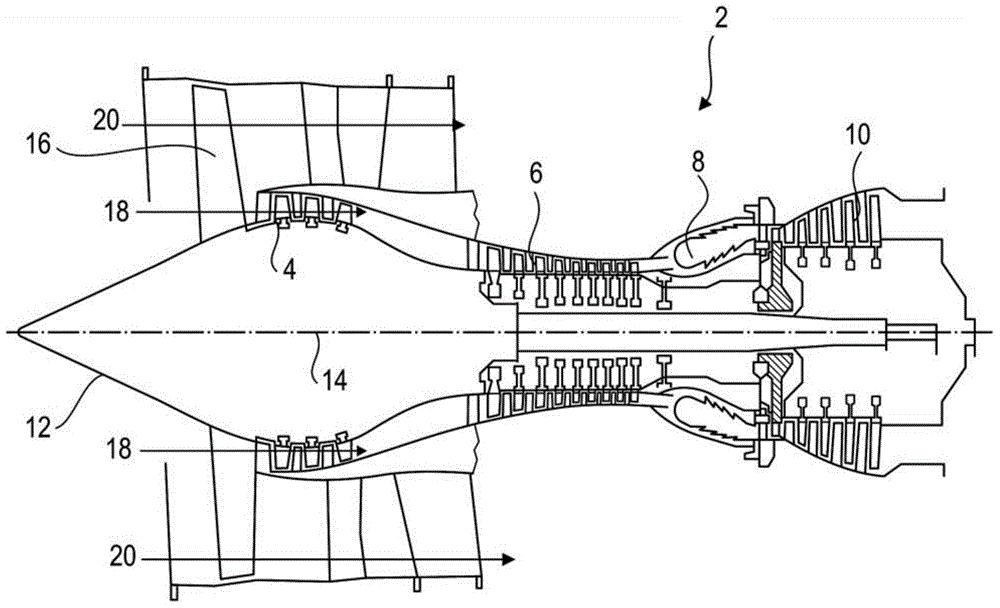

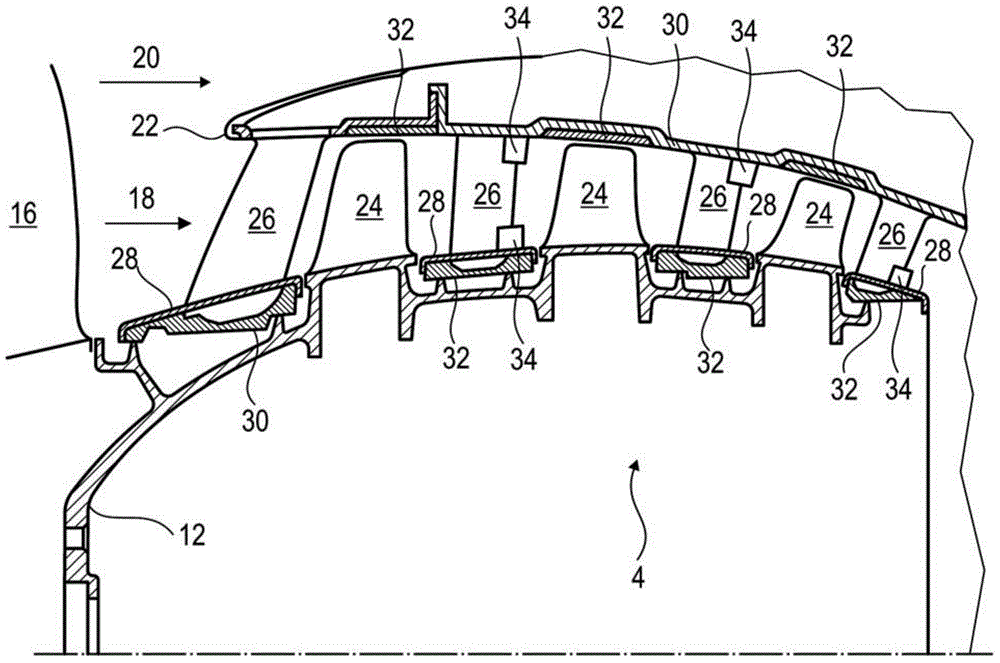

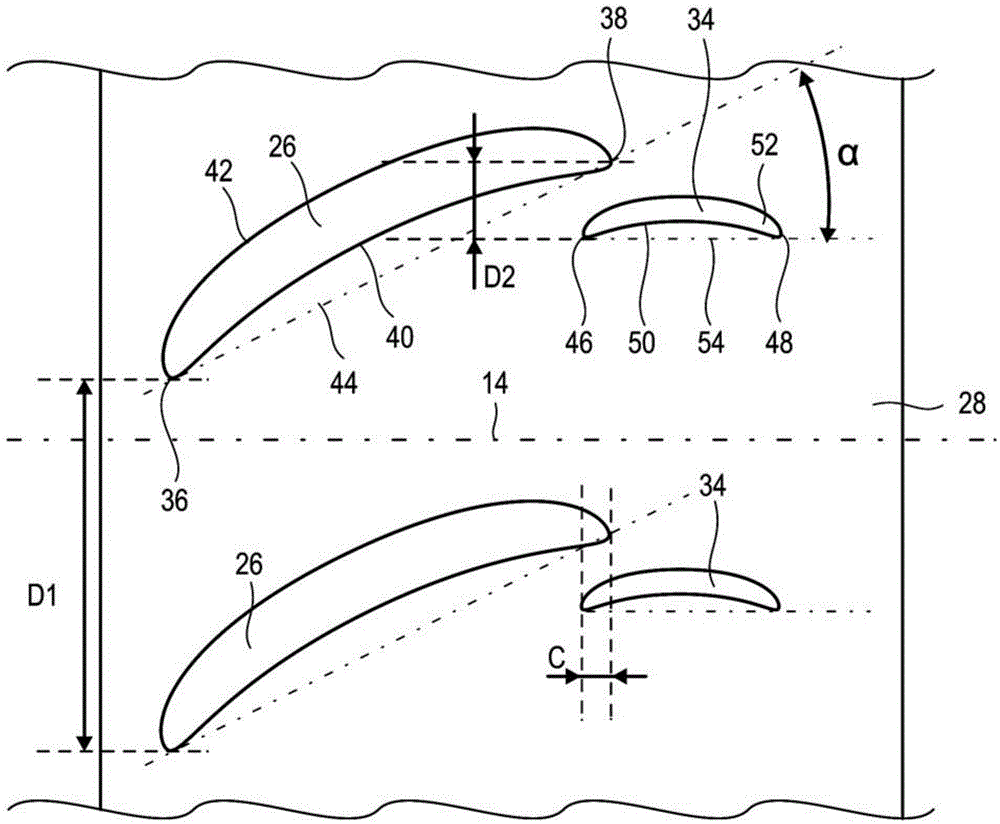

[0041] figure 1 An axial turbine is shown schematically. In this case a twin-flow turbojet. The turbojet comprises a first compression stage (the so-called low-pressure compressor 4 ), a second compression stage (the so-called high-pressure compressor 6 ), a combustion chamber 8 and one or more turbine stages 10 . In operation, the mechanical power of the turbine 10 is transmitted through the central shaft to the rotor 12 which then drives the two compressors 4 and 6 . A reduction mechanism may increase the rotational speed delivered to the compressor. Furthermore, the different turbine stages can be connected to the compressor stages by concentric shafts. The compressor stages include rows of rotor blades associated with rows of stator blades. The rotation of the rotor thus generates an air flow which is then gradu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com