Self-cooling circulation axial force carrying device for horizontal pump

A bearing device and axial force technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, pumps, etc., can solve the problem of complex pump structure, large accumulated residual axial force, and axial force Poor balancing effect and other problems, to achieve the effect of improving service life and scope of use, reducing maintenance cycle and maintenance costs, and reducing pressure level requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

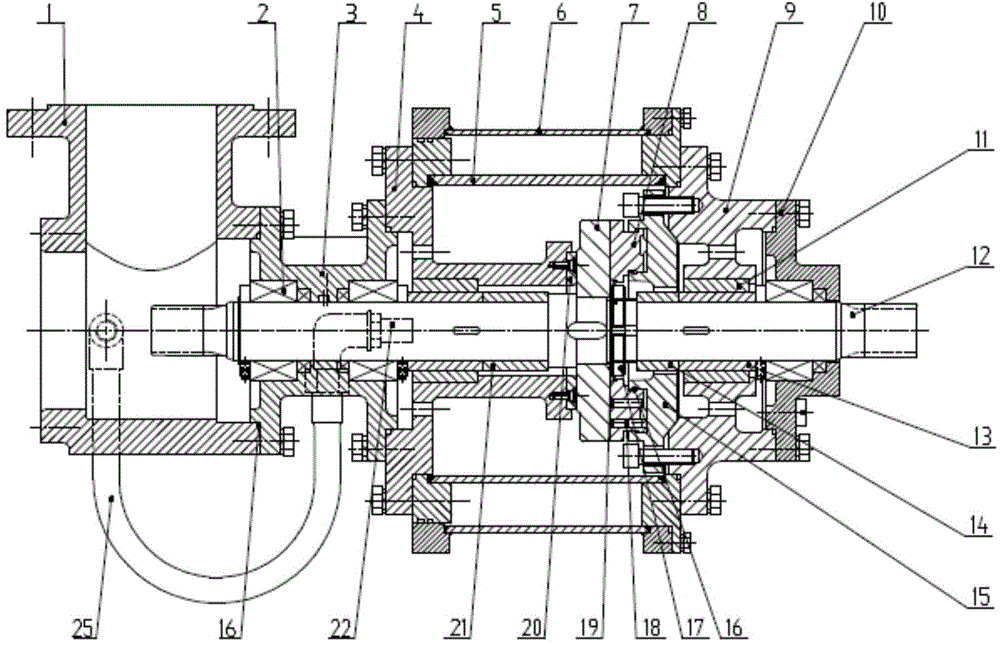

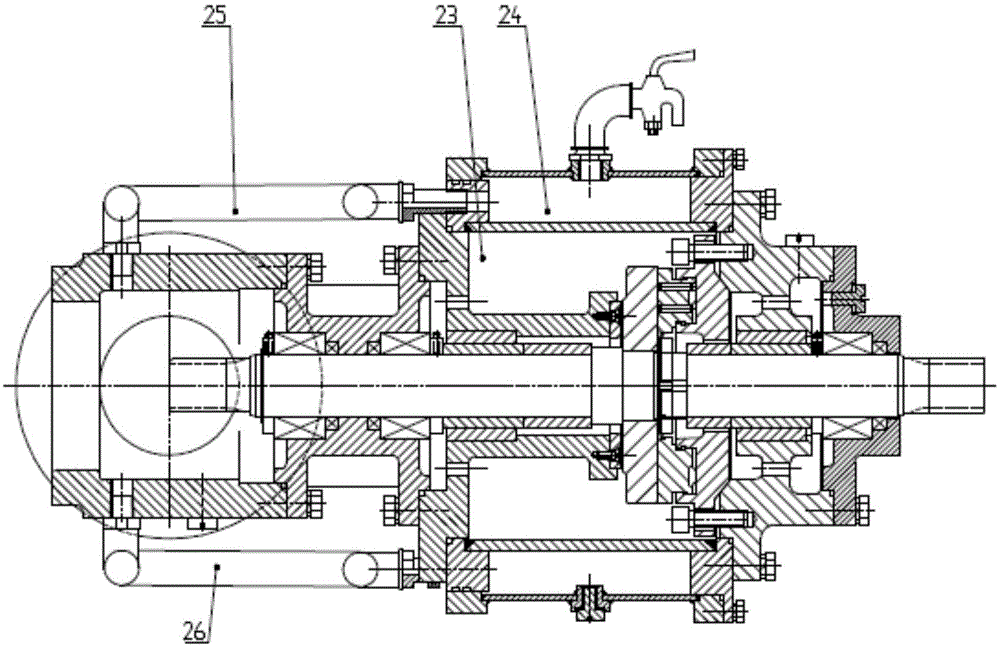

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

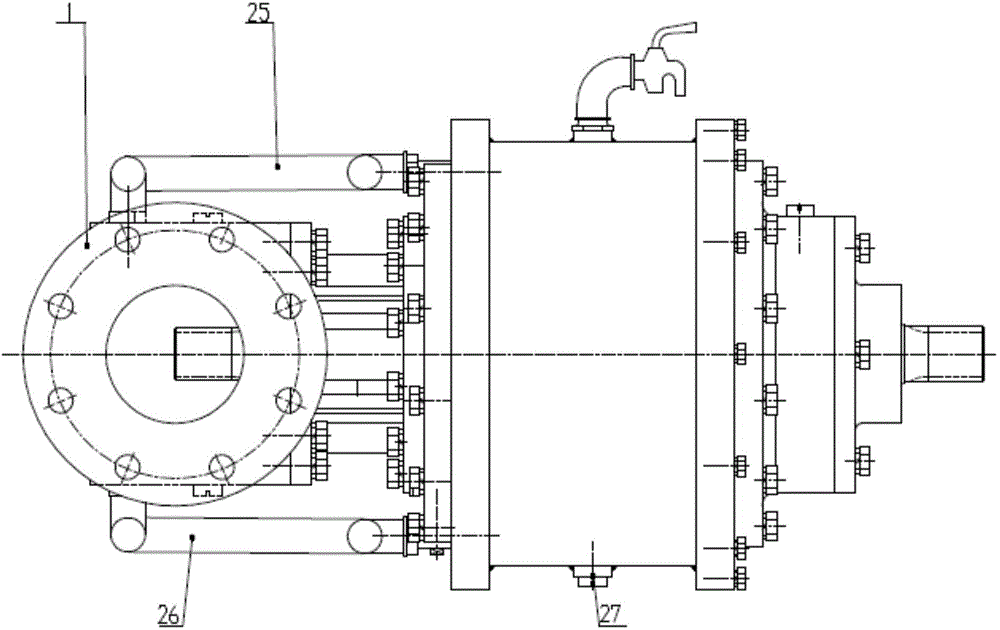

[0020] See Figure 1 ~ Figure 3 , a self-cooling cycle axial force bearing device for a horizontal pump, including an inlet flange 1 and a pump shaft, and also includes a transmission shaft 12 connected to the pump shaft. On the transmission shaft 12, from left to right The connecting piece 3, the thrust bearing unit and the tail end cover 10 are sequentially socketed; a mechanical seal 2 is provided between the connecting piece 3, the tail end cover 10 and the transmission shaft; the thrust bearing unit includes The front bearing housing 4 and the front bearing 20, slider 7, thrust bearing sector 8, thrust bearing bracket 15 and rear bearing housing 9 arranged in sequence from left to right; The left end surface of the bearing bracket 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com