Water spraying mechanism in air purification system and control method thereof

An air purification system and control method technology, applied in the field of environmental management, can solve the problems that the water spray area unit cannot be changed accordingly, and the negative ion concentration of the air purification system cannot be optimized, so as to improve human comfort and save water and energy. , the effect of increasing the concentration of negative ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

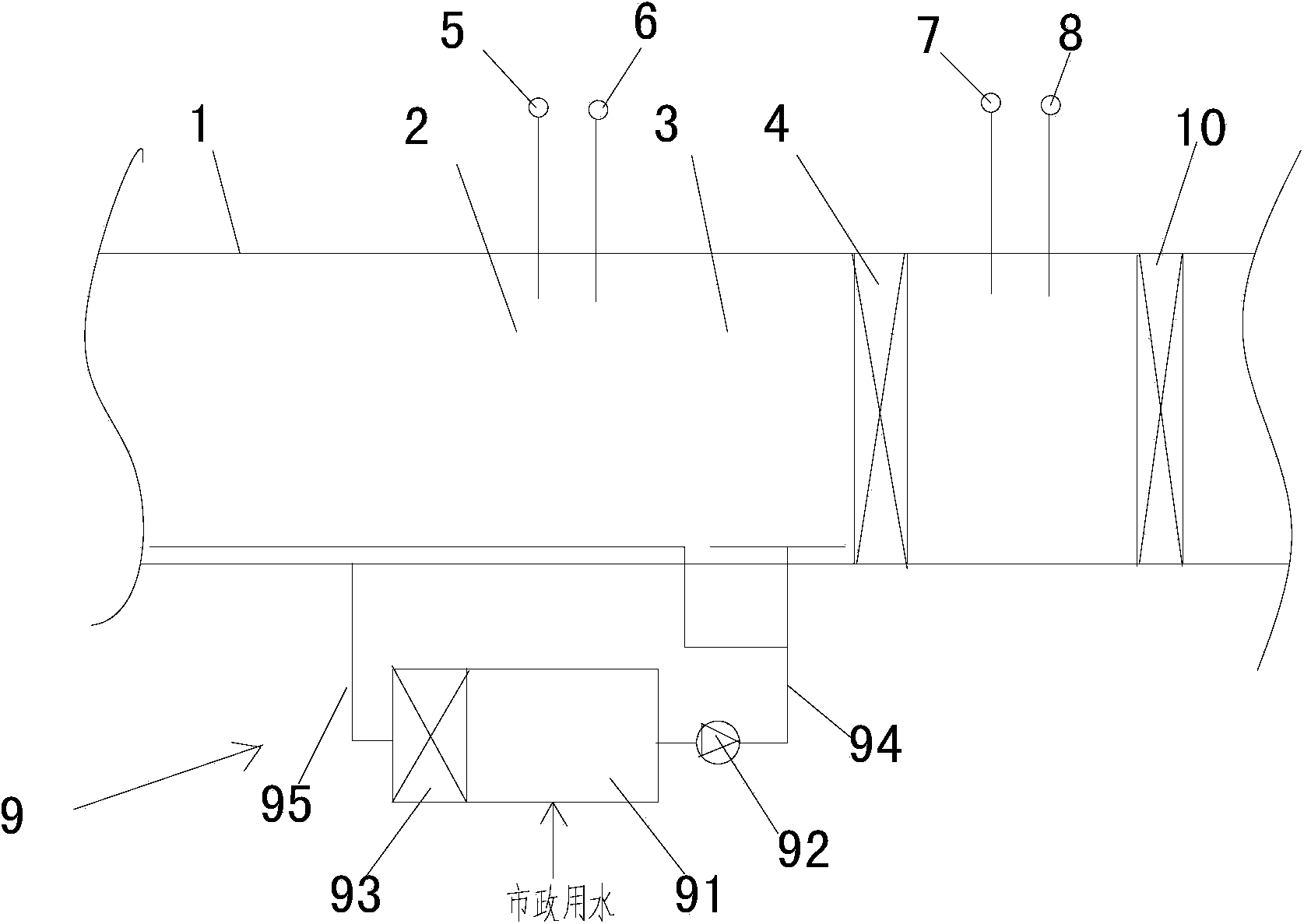

[0053] see figure 1 , the water spraying mechanism in the air purification system of the present invention includes a water spraying area 2, a water mist spraying area 3, a water-gas separation device 4, a wind speed sensor 5, a wind pressure sensor 6, The temperature and humidity sensor 7 and the negative ion concentration sensor 8, as well as the water supply and return device 9 and the control unit (not shown) arranged outside the air duct. The water spray area, water mist spray area and water-air separation device are arranged in sequence along the air duct; the wind speed sensor and wind pressure sensor are respectively arranged in the air duct at the front of the mechanism, and the temperature and humidity sensor and the negative ion concentration sensor are respectively arranged at the rear of the mechanism In the air duct; the water supply and return device includes a water supply pipeline and a return water pipeline, which are respectively connected to the water spray...

Embodiment 2

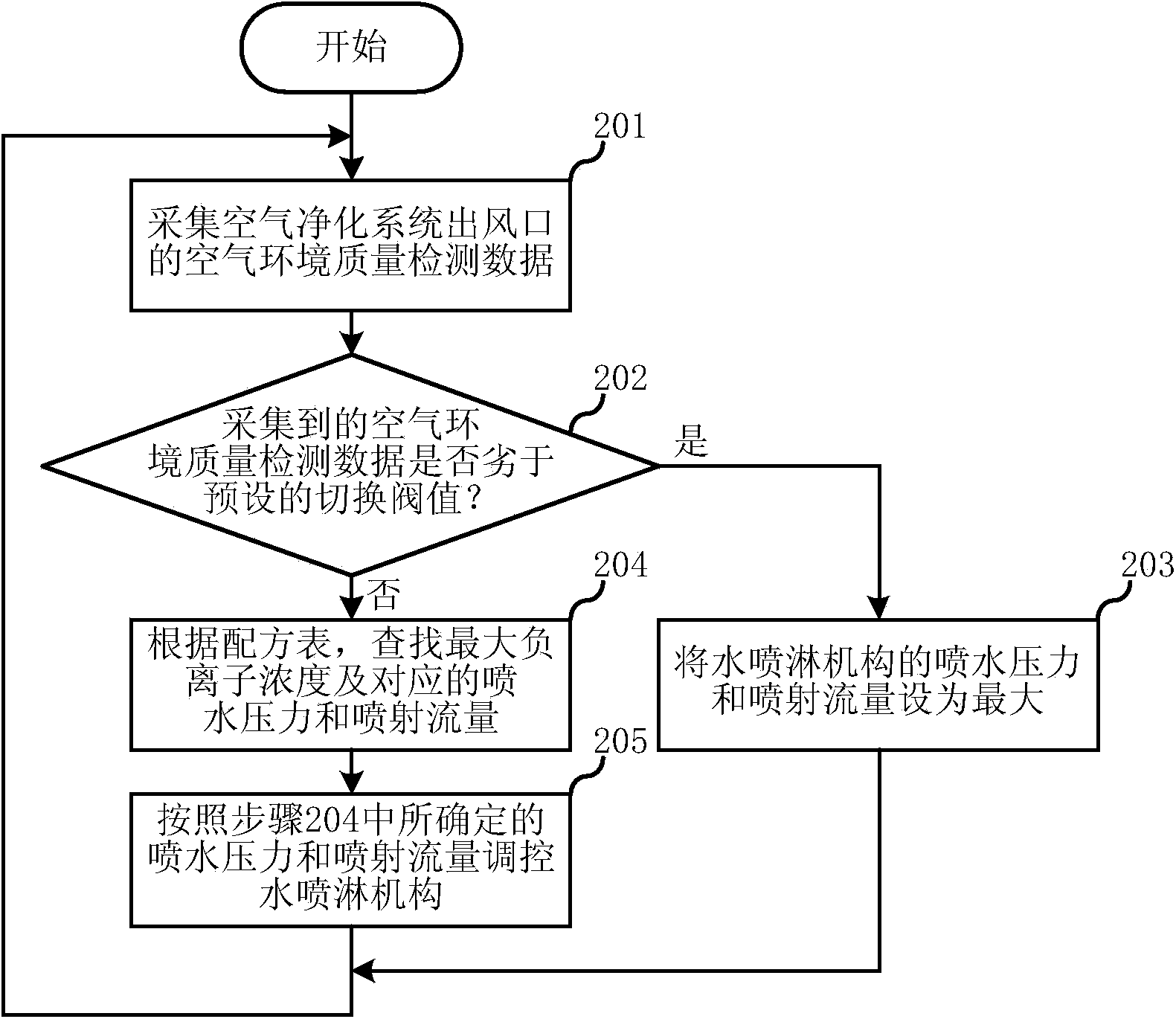

[0062] The control method of the water spray mechanism of the air purification system in this embodiment includes two control modes of maximum water pressure and flow control mode and negative ion concentration control mode. By collecting the air environment quality detection data of the air outlet of the air purification system, the collected The detected air environment quality detection data is compared with the preset switching threshold, and the maximum water pressure and flow control mode and the negative ion concentration control mode are switched according to the comparison result.

[0063] Since the change of the negative ion concentration value is related to the results of the comprehensive changes in the wind speed, nozzle pressure, flow rate, temperature, humidity and other parameters in the air inlet duct, there is no fixed mathematical function model. In this embodiment, wind speed and water spray pressure are used as the main variables for adjustment, and the adj...

Embodiment 3

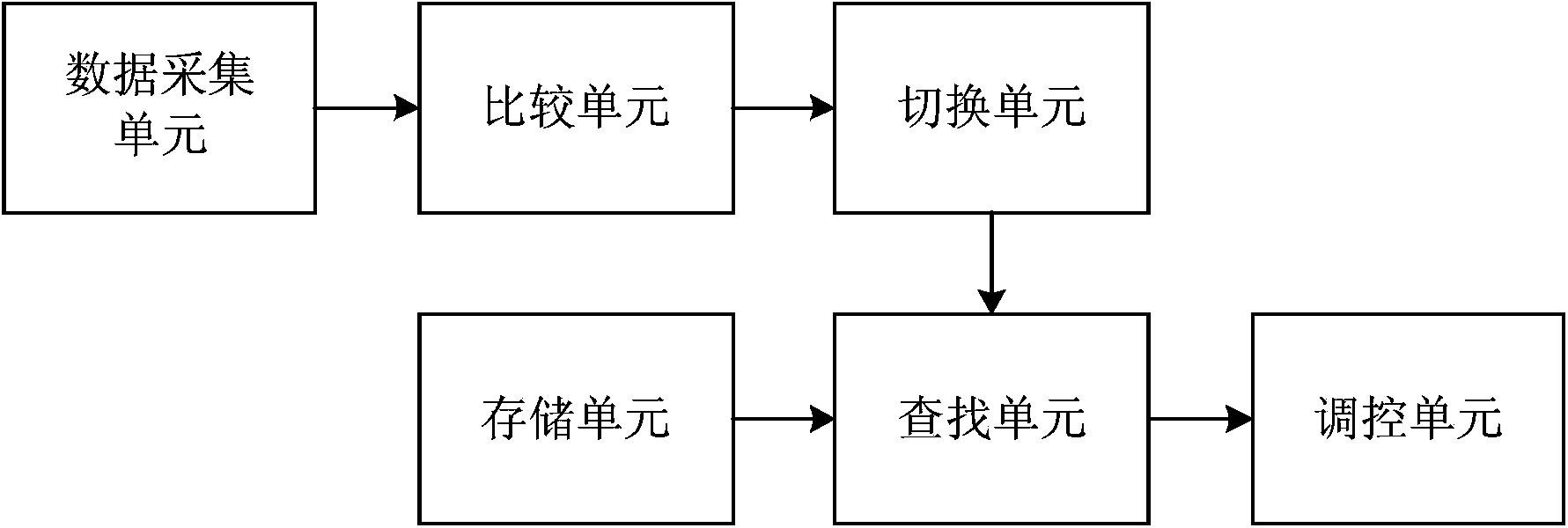

[0078] Embodiment 3 is based on Embodiment 1, and further introduces the control unit therein. Such as image 3 As shown, the control unit of the water spray mechanism of the air purification system includes:

[0079] The storage unit is used to store the corresponding relationship between the wind speed at each level of the water spray mechanism, the water spray pressure at all levels, the jet flow at each level and the concentration of negative ions obtained from the test under the current equipment environment, and form a formula table; In the test, wind speed and water spray pressure are used as the main variables, and the injection flow is used as the secondary variables;

[0080] The search unit is used to determine the maximum anion concentration corresponding to the current wind speed range, and the water spray pressure and spray flow rate corresponding to the anion concentration according to the formula table;

[0081] A regulating unit, configured to regulate the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com