A device for measuring root-soil friction force

A measuring device and friction force technology, which is applied in the field of root-soil root system friction measuring devices, can solve the problems of inaccurate recording of experimental data, large human interference factors, etc., and achieve simple and flexible measuring devices, increased accuracy, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

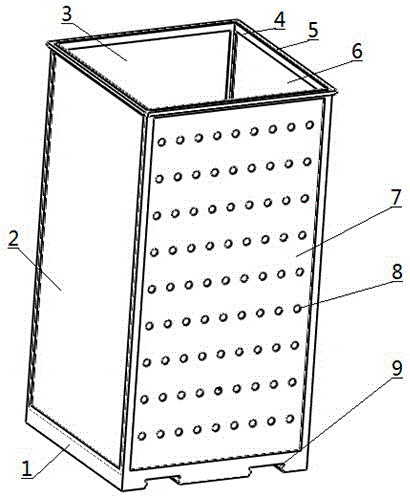

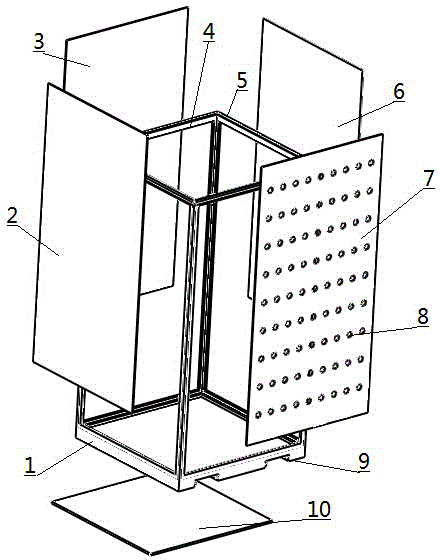

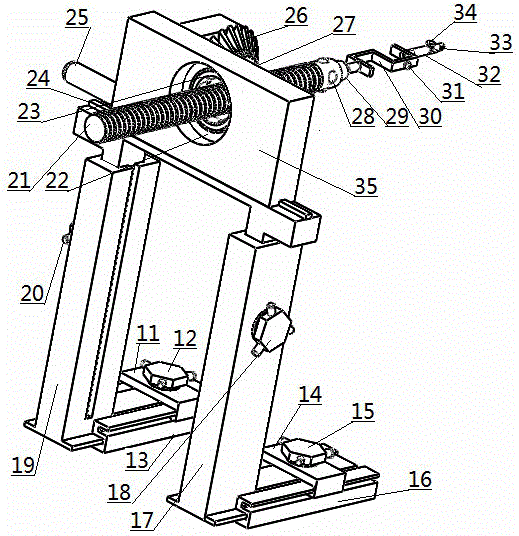

Embodiment 1

[0018] Embodiment 1: as Figure 1-6 As shown, a root-soil root system friction measuring device includes a root system burying device and a measuring device; the root system burying device includes a frame base 1, a left baffle 2, a rear baffle 3, a card slot 4, a handle 5, and a right baffle 6. Front baffle 7, root hole 8, slide rail groove 9 and bottom baffle 10; slide rail groove 9 is provided at the bottom of the frame base 1, and card slots 4 are respectively provided on the front, rear, left, and right sides of the root system burying device for inserting stoppers. When in use, the baffle is inserted into the card slot 4 from top to bottom perpendicular to the bottom. The baffle is mainly divided into a left baffle 2, a rear baffle 3, a right baffle 6 and a front baffle 7, wherein the front baffle 7 consists of Root system holes 8 are arranged in equal rows from top to bottom, and the number of holes in each row on the front baffle 7 is equal and distributed at equal int...

Embodiment 2

[0021] Embodiment 2: as Figure 1-6 As shown, a root-soil root system friction measuring device includes a root system burying device and a measuring device; the root system burying device includes a frame base 1, a left baffle 2, a rear baffle 3, a card slot 4, a handle 5, and a right baffle 6. Front baffle 7, root hole 8, slide rail groove 9 and bottom baffle 10; slide rail groove 9 is provided at the bottom of the frame base 1, and card slots 4 are respectively provided on the front, rear, left, and right sides of the root system burying device for inserting stoppers. When in use, the baffle is inserted into the card slot 4 from top to bottom perpendicular to the bottom. The baffle is mainly divided into a left baffle 2, a rear baffle 3, a right baffle 6 and a front baffle 7, wherein the front baffle 7 consists of Root system holes 8 are arranged in equal rows from top to bottom, and the number of holes in each row on the front baffle 7 is equal and distributed at equal int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com