Gas-expansion-type temperature-light-sensitive thermotropic gravity center automatic adjustment device

A gas expansion and automatic adjustment technology, applied in the direction of control using feedback, can solve the problems of energy consumption, high cost, damage feedback, etc., and achieve the effects of no energy consumption, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

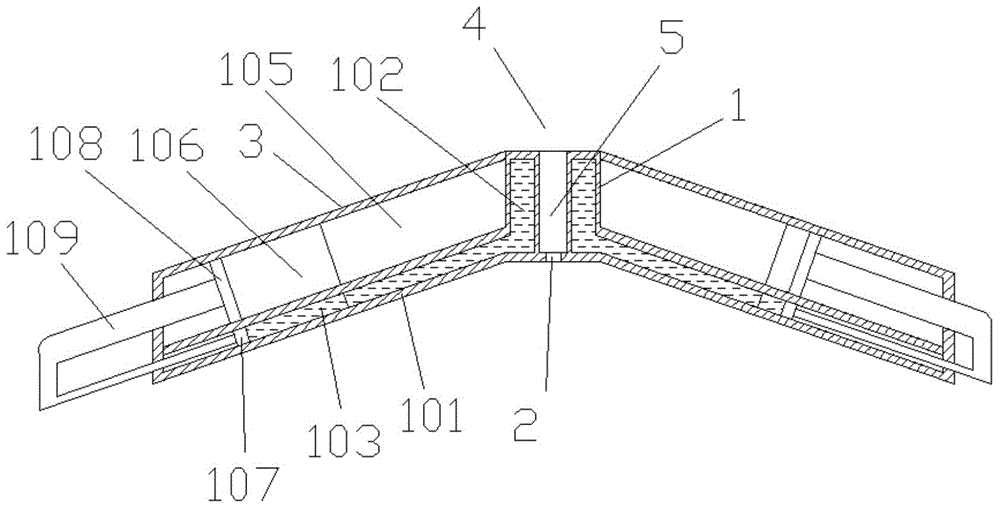

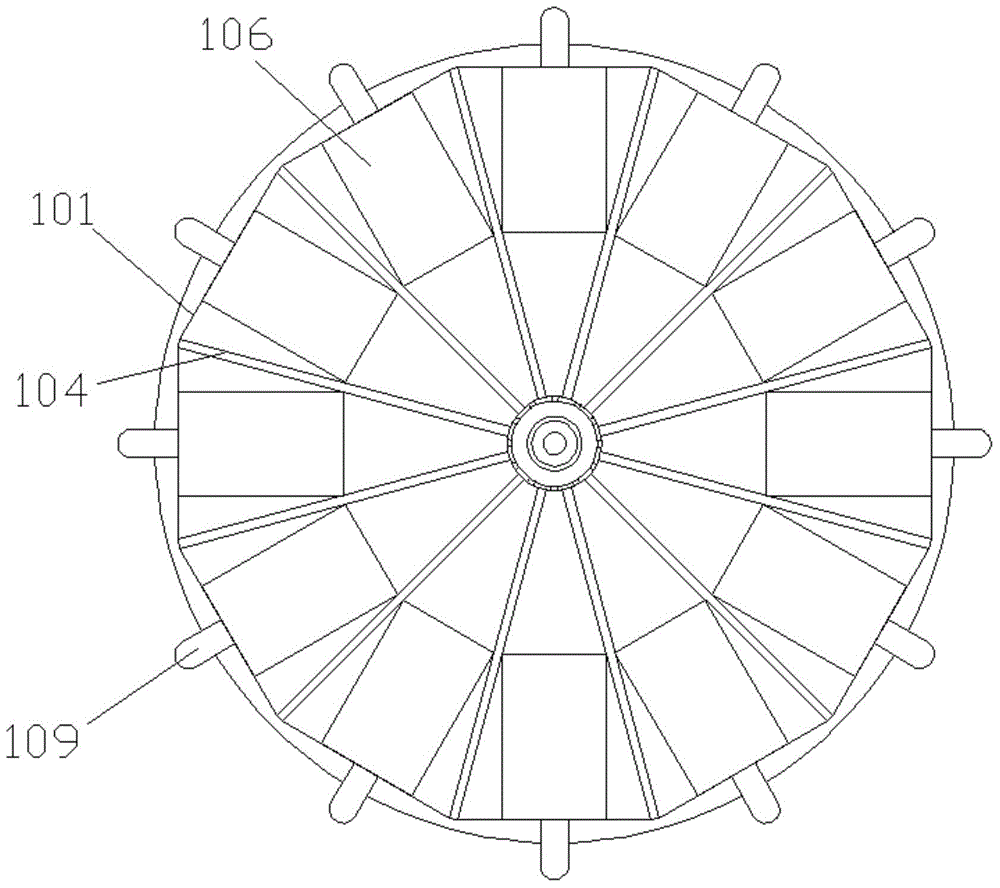

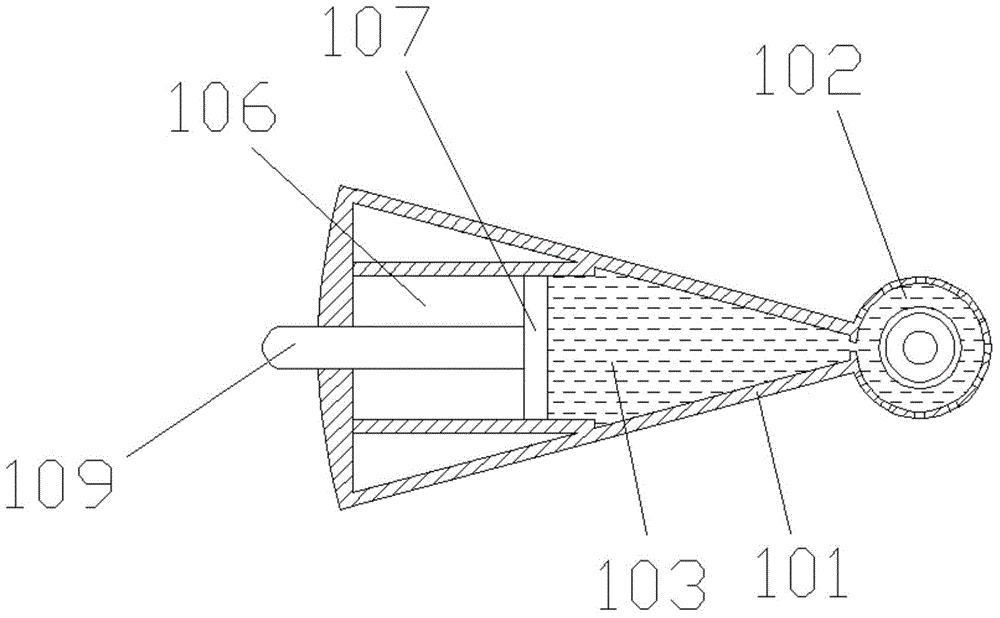

[0021] refer to figure 1 As shown, a gas expansion type temperature-photosensitive automatic center of gravity adjustment device includes a liquid storage tank 1, a central installation connection reserved position 2, a heat-sensitive energy absorber 3, a vertical level indicator 4 and an installation avoidance position 5, The liquid storage chamber 1 includes a liquid storage chamber unit 101, a liquid storage compensation chamber 102, and a thermal expansion and contraction gas storage chamber 105. The liquid storage compensation chamber 1 is located in the middle of the device, and the liquid storage chamber unit 101 and thermal expansion The cold-shrinkage gas storage chamber 105 is composed of a plurality of uniformly distributed units, which are connected to each other to form a cone, enclosing the liquid storage compensati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com