A row-type carbon fiber heating tube

A carbon fiber and heating tube technology, applied in the field of carbon fiber, can solve the problems of small heating area and low heat conversion rate, and achieve the effects of stable current, improved heat conversion rate, and enhanced external impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

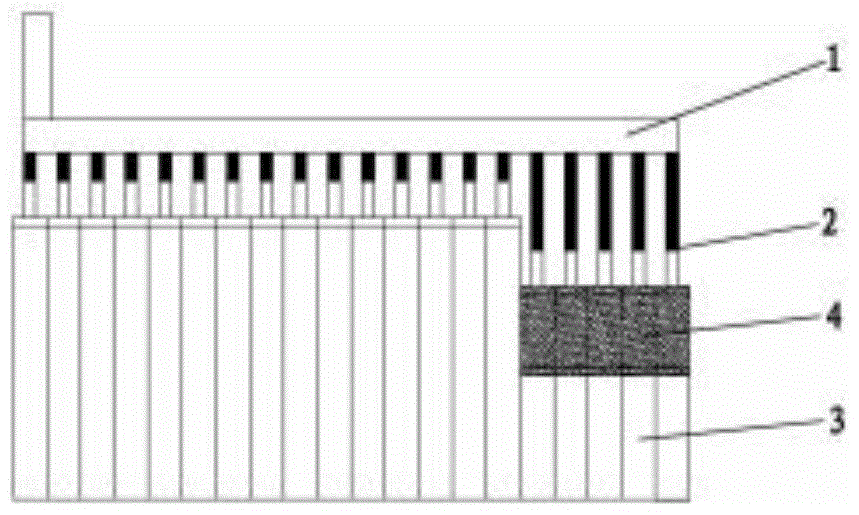

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0017] combined with figure 1 As shown, it is a row-pipe carbon fiber heating tube according to an embodiment of the present invention, which includes a row tube 3, a double-layer hollow structure formed by sleeves of inner and outer shell walls, and the material used for the inner and outer shell walls is polybutylene vinyl material; the base core 2 is located in the inner shell wall, the base core 2 is cylindrical, and the base core 2 is composed of carbon fiber bundles coated with glass fibers and silica gel coating, from the carbon fiber bundles There is also a wire passing through the center; the power terminal covers one end of the wire and is used to connect the wire with an external power supply; wherein, the shell wall is a thin-walled structure formed by connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com