Profile part and equipment cabinet with profile part

A profile and component technology, applied in the direction of rack/frame structure, chassis/cabinet/drawer parts, etc., can solve the problems that are not conducive to large-scale material preparation, increase operational risks, increase cabinet weight, etc., and reduce material preparation. Risk, easy on-site assembly, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

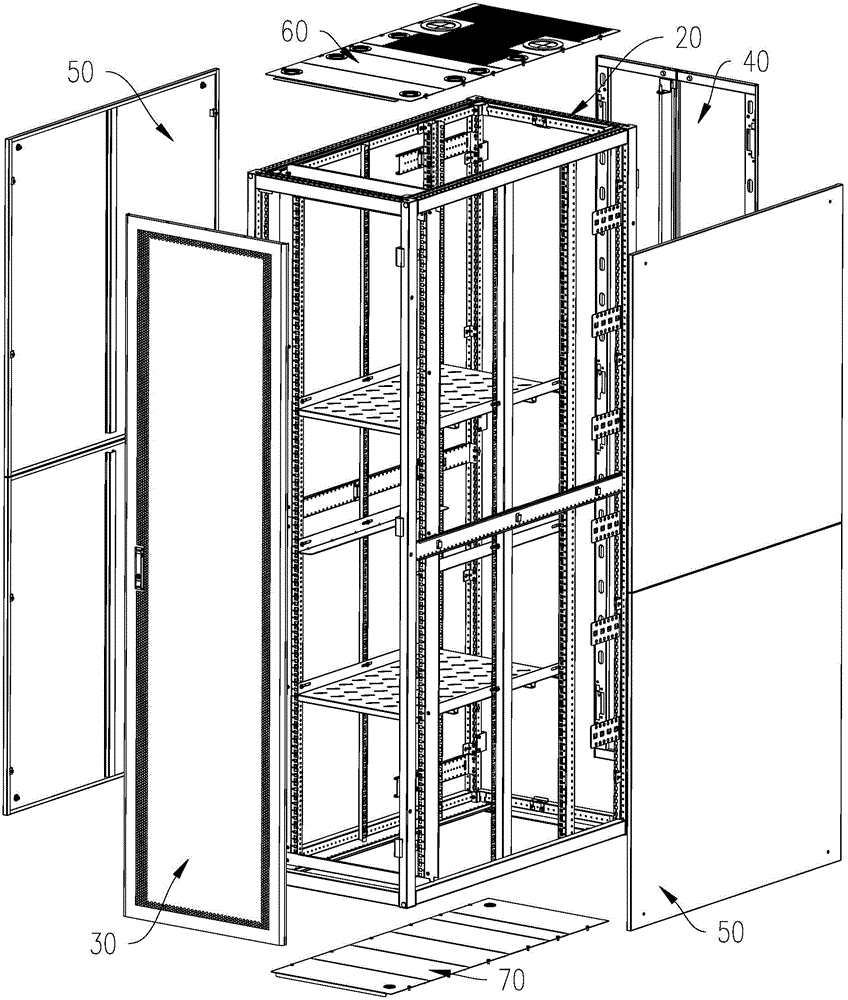

[0038] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

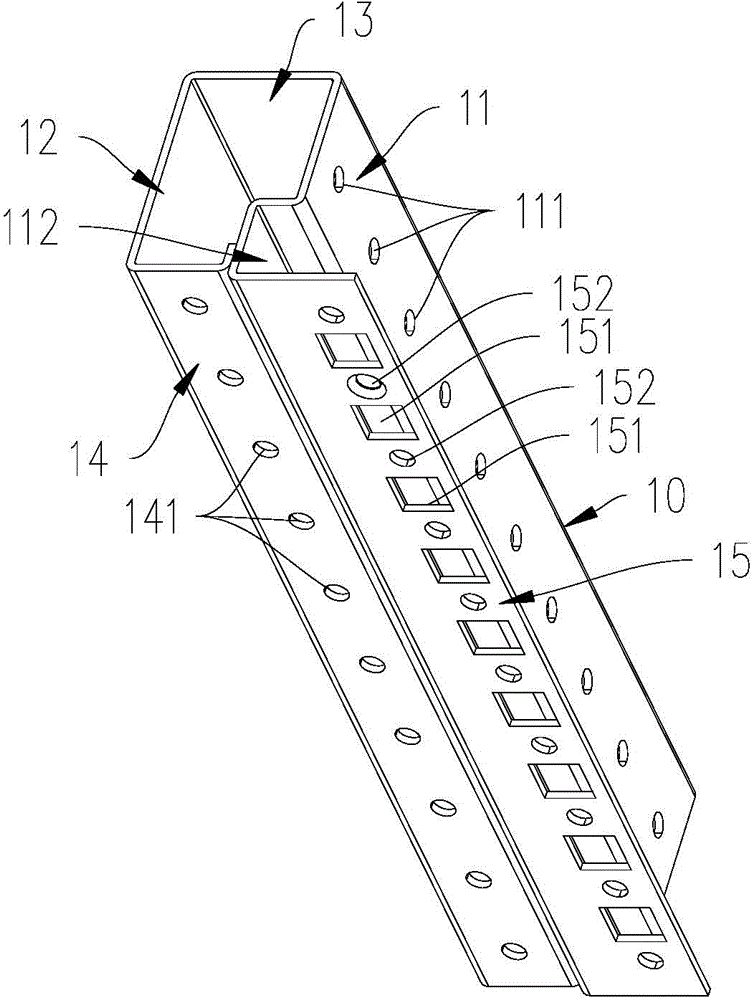

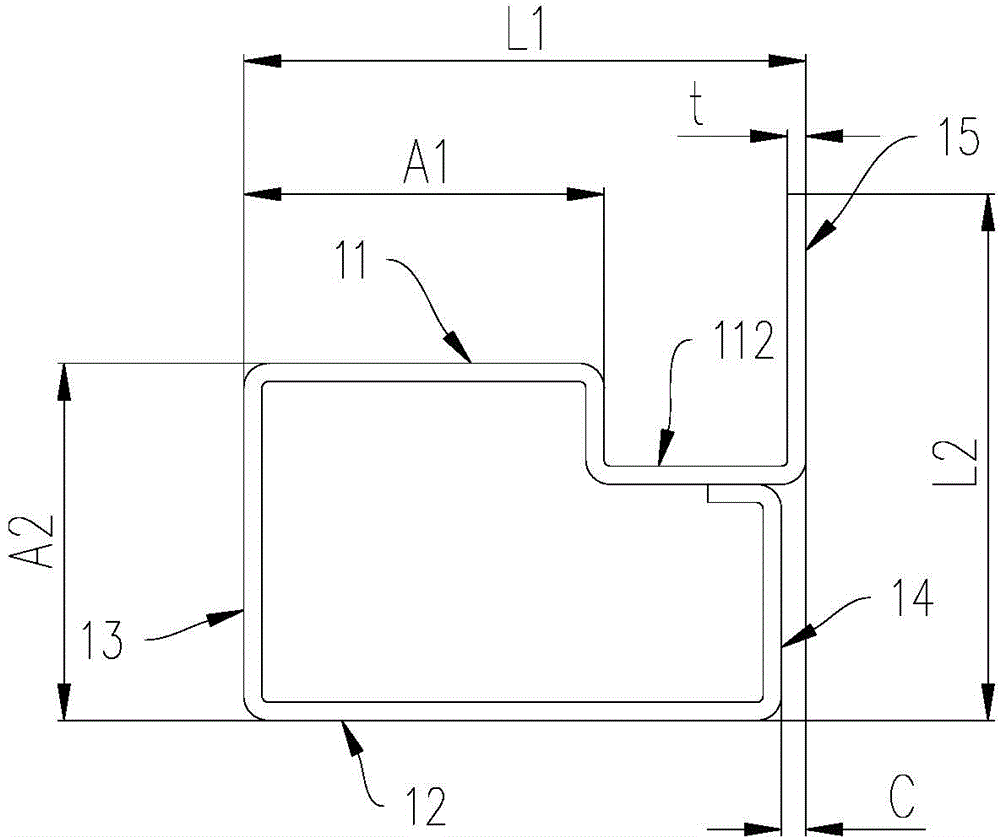

[0039] Such as figure 1 As shown, the profile member in a preferred embodiment of the present invention includes a profile 10, and the profile 10 includes two opposite first side plates 11, a second side plate 12 and two opposite third side plates 13, a fourth side plate 14 The enclosed profile body; the profile 10 also includes a fifth side plate 15 extending outward perpendicular to the first side plate 11 . The fifth side plate 15 and the fourth side plate 14 are located on the same side of the first side plate 11 , and the fifth side plate 15 is respectively provided with a plurality of first connecting holes 151 along the longitudinal direction.

[0040] Preferably, the profile 10 is a profile in which the fifth s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com