Bead ring winding device

A technology of a coiling device and a bead ring, which is applied to tires, rings made from wires, and other household appliances, etc., can solve the problem of inability to coil a tapered bead ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

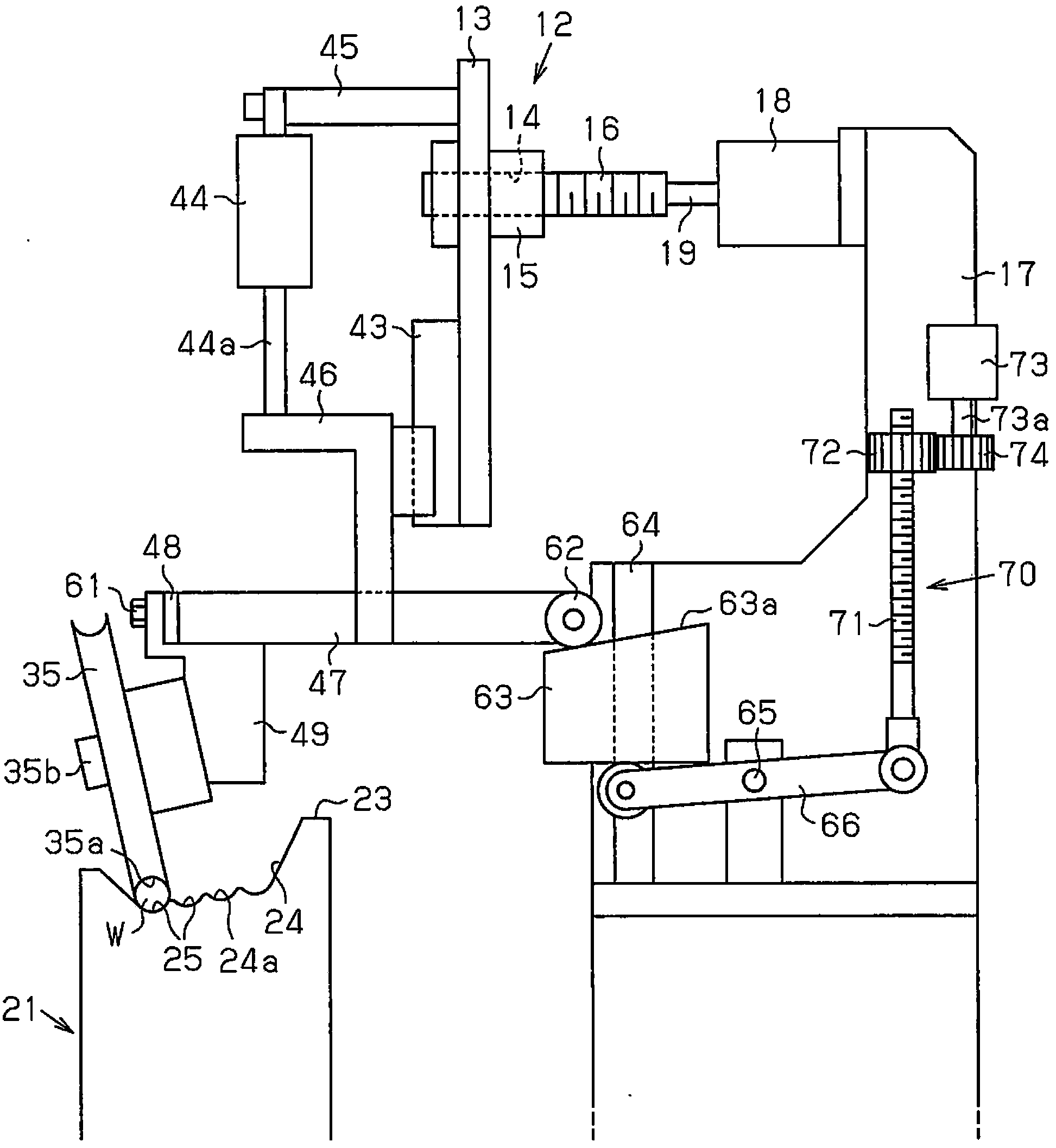

[0024] The following follows Figure 1 to Figure 5 One embodiment of a traveler winding device embodying the present invention will be described.

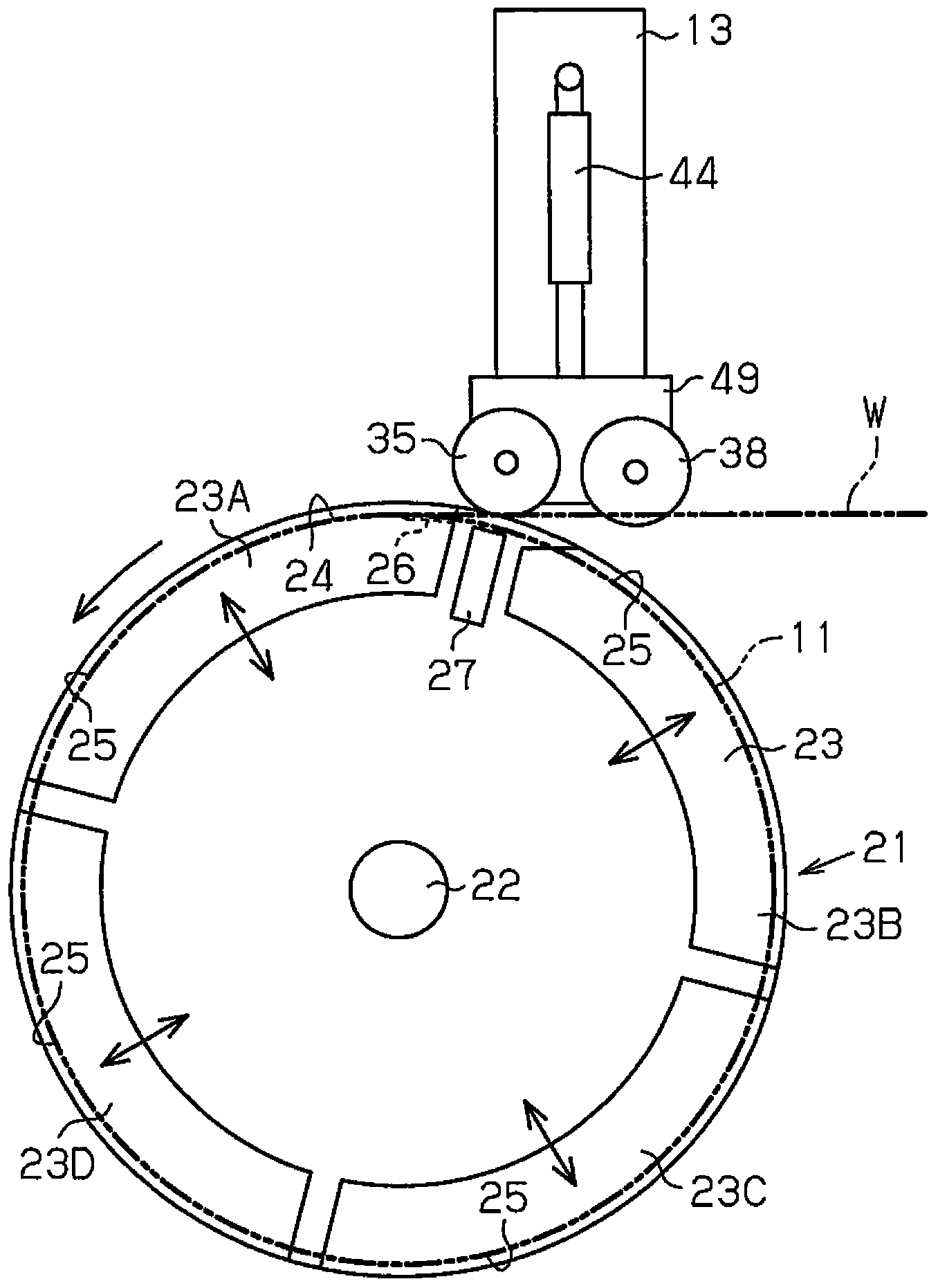

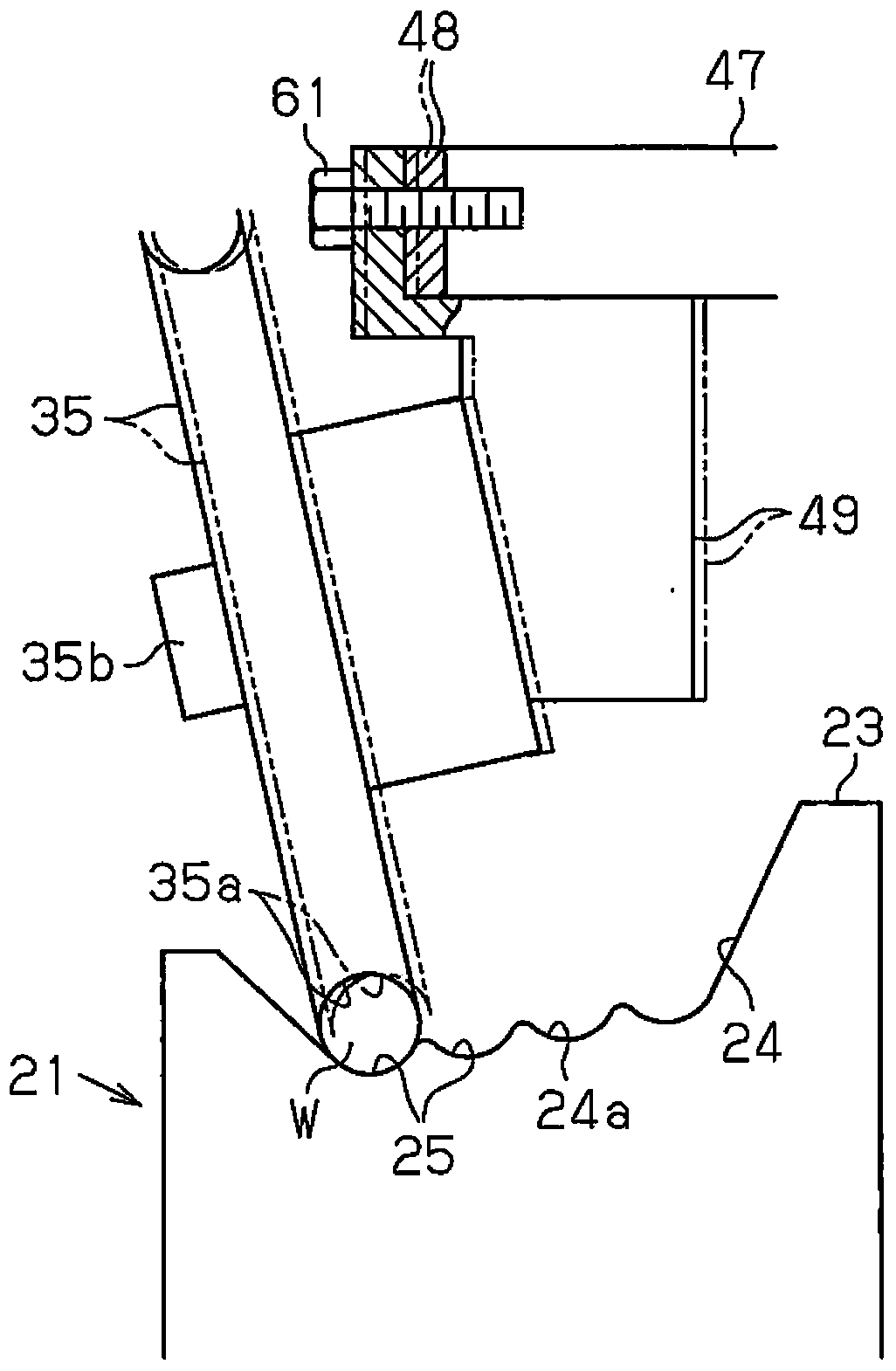

[0025] Such as figure 2 As shown, the rotating body 21 is supported on the frame 17 of the winding device in a manner capable of rotating about a rotating shaft (horizontal shaft) 22 (see figure 1 )superior. An annular winding portion 23 for winding the wire W is provided on the outer peripheral surface of the rotating body 21 . The winding portion 23 is divided in the circumferential direction. The take-up unit 23 is constituted by a plurality of divided bodies 23A to 23D supported so as to be movable in the radial direction of the rotating body 21 . The wire W is formed by covering the outer peripheral surface of the wire with a coating such as rubber.

[0026] Such as figure 1 as well as figure 2 As shown, on the outer peripheral surface of each of the divided bodies 23A to 23D, in order to form the traveler 11 by windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com