Arc-shaped molybdenum plate and manufacturing method and application thereof

A manufacturing method and molybdenum sheet technology, applied in metal processing equipment and other directions, can solve problems such as affecting assembly production, maintaining straightness, unable to support electrodes, etc., to achieve the effect of maintaining bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

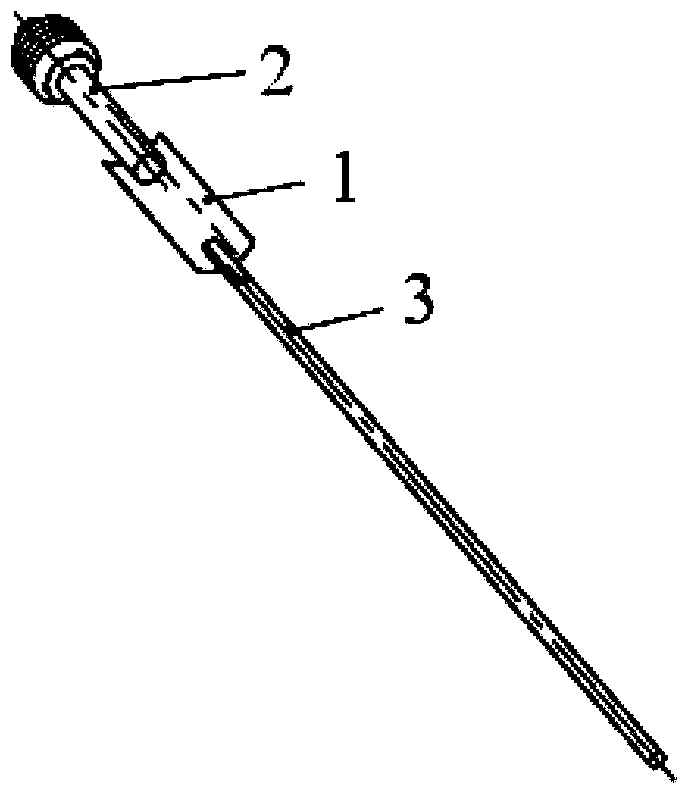

[0018] An arc-shaped molybdenum sheet 1, the cross-section of the arc-shaped molybdenum sheet 1 is an arc-shaped structure, the width of the arc-shaped molybdenum sheet 1 is 2.2-4mm, the thickness is 0.02-0.04mm, and the radian of the molybdenum sheet is 1.0-1.6 rad. This arc-shaped molybdenum sheet 1 is used for connecting electrode 2, and electrode 2 is spot-welded on one end of arc-shaped molybdenum sheet 1, and the other end of arc-shaped molybdenum sheet 1 is welded molybdenum bar 3, as figure 1 As shown, the arc-shaped structure is adopted to increase the supporting strength of the molybdenum sheet and ensure the straightness of the components after assembly. .

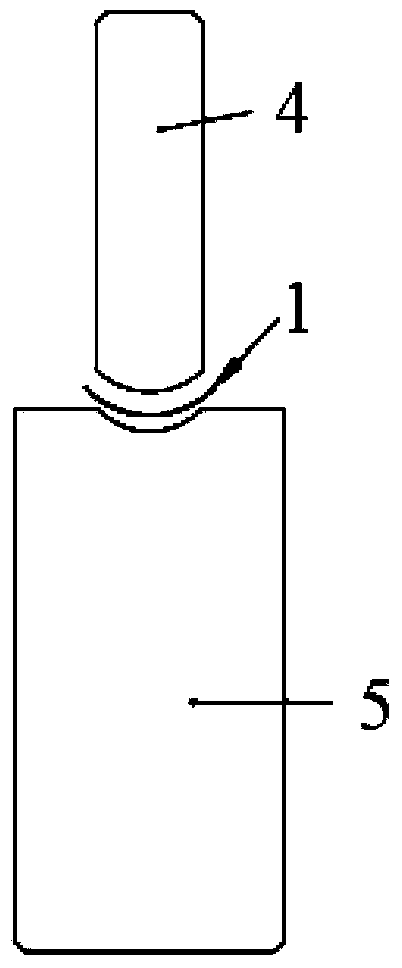

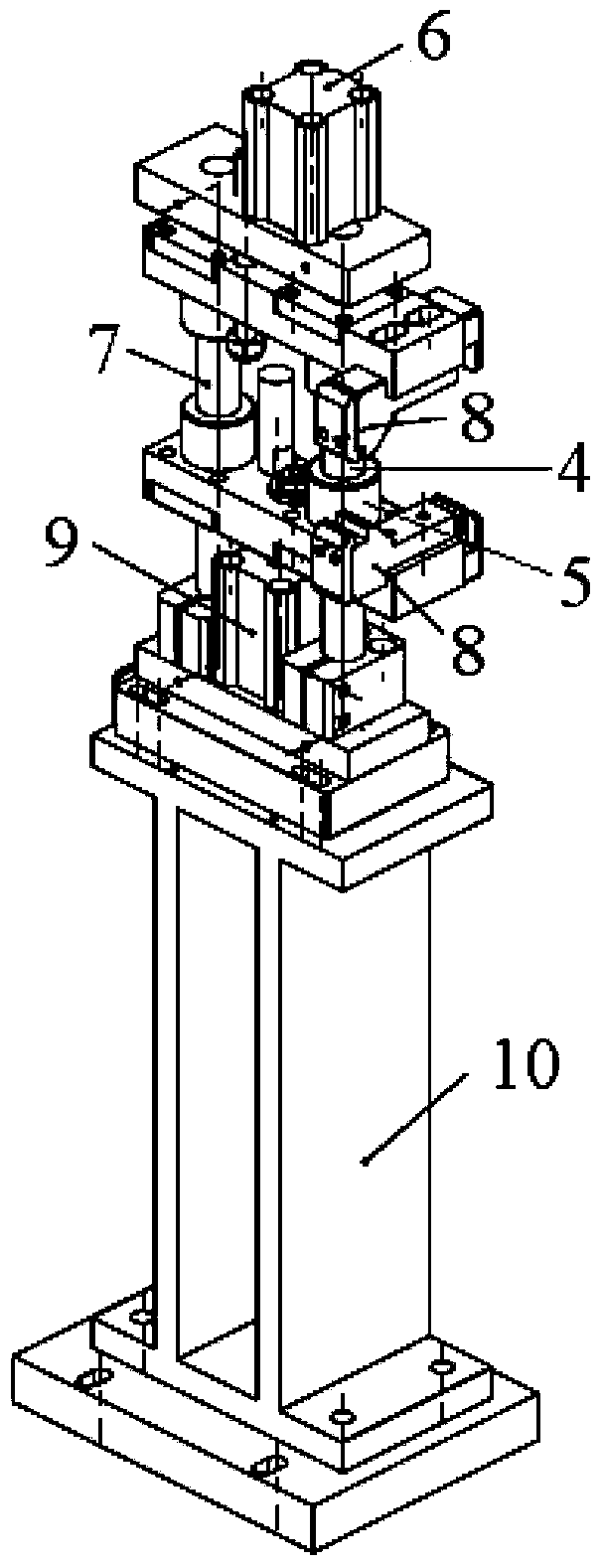

[0019] In this method, the smooth molybdenum sheet is placed in a pressing mold, and the arc-shaped molybdenum sheet is produced through the clamping process of the upper punch 4 and the lower die 5, such as figure 2 As shown, using the upper punch 4 and the lower die 5 can ensure that the edges on both sides...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com