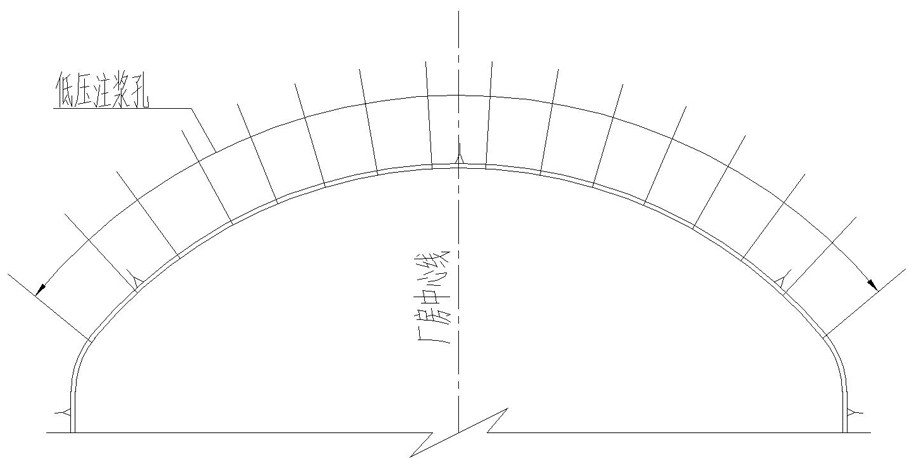

Underground cavern top arch shallow surface layer surrounding rock low-pressure grouting method

A technology for underground caverns and shallow surfaces, applied in underground caverns, earthwork drilling, shaft equipment, etc., can solve the problem of weakening the integrity and bearing capacity of surrounding rock itself, expanding the relaxation circle of surrounding rock, and threatening the safety of underground caverns To improve the stress transfer performance and maintain the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present embodiment is a low-pressure grouting method for the surrounding rock of the shallow surface layer of the top arch of an underground cavern, which specifically includes the following steps:

[0020] S1. Before low-pressure grouting, all support measures for the location where low-pressure grouting is to be carried out on the top arch of the underground cavern shall be completed.

[0021] S2. Complete the grouting hole setting and opening of the corresponding parts of the top arch of the underground cavern. The grouting hole should be set out accurately, and the relative position with the constructed anchor cable and monitoring instrument should be reviewed before opening to avoid damage to the original anchor cable and monitoring equipment. The site is based on the principle of uniform arrangement, mutual staggering, and no damage to monitoring instruments. Effective measures must be taken in drilling to improve drilling accuracy and avoid excessive drillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com