Storage shelf

a storage shelf and shelf body technology, applied in the field of storage shelves, can solve the problems of inability to support the object to be vibration-isolated, the object may be subject to vibration transmission, etc., and achieve the effects of reducing vibration, reducing vibration, and maintaining load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

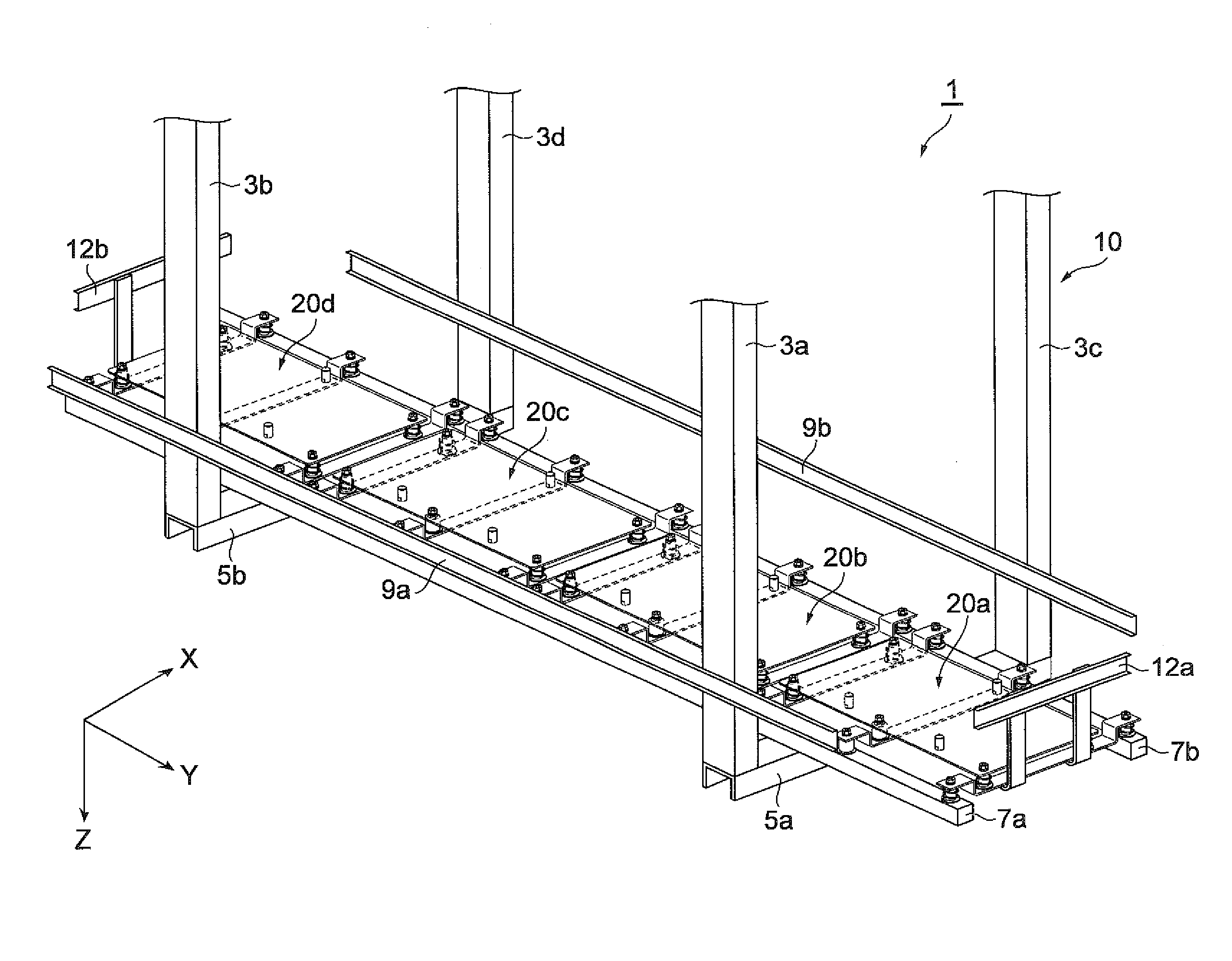

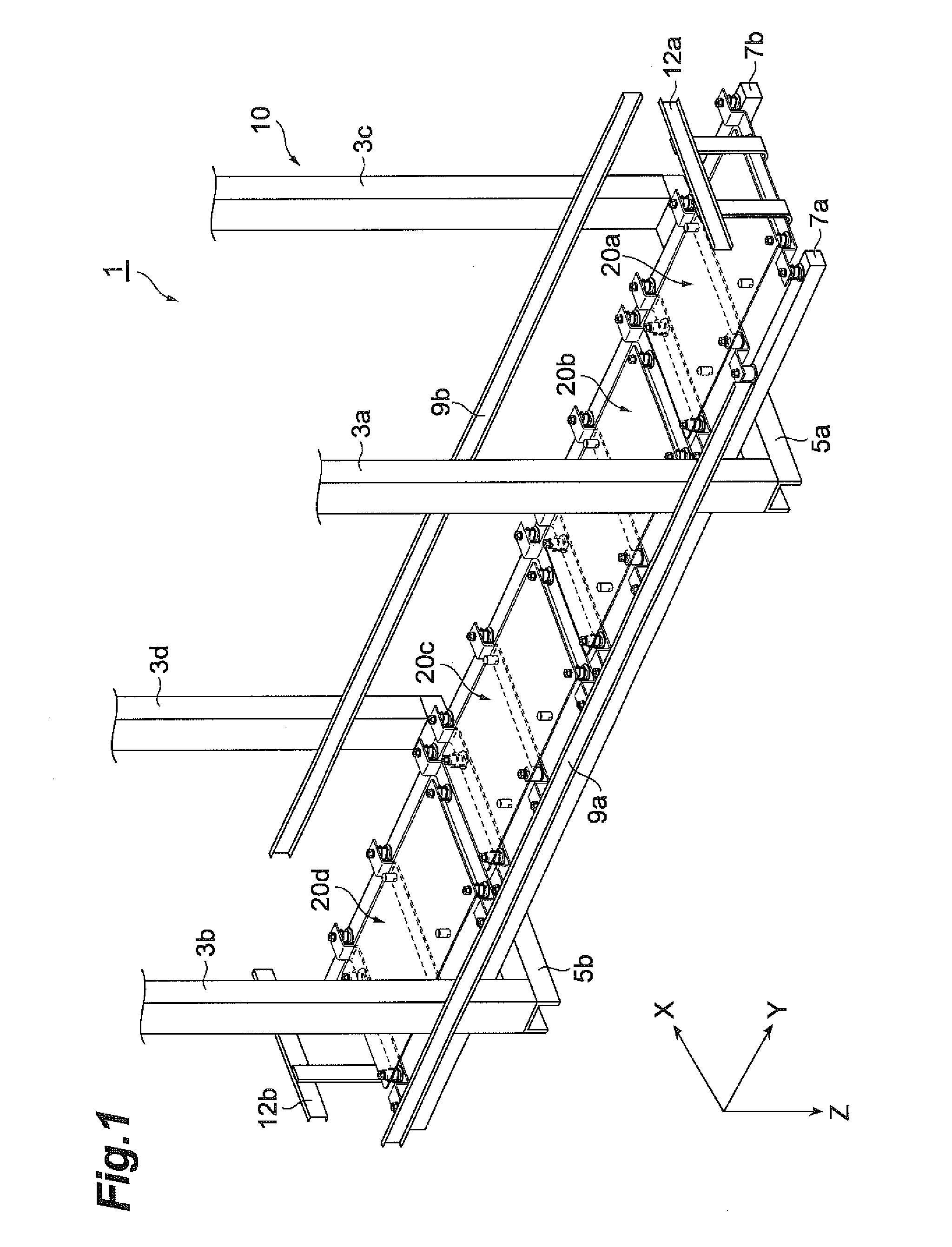

[0023]FIG. 1 is a perspective view illustrating a storage shelf according to a preferred embodiment of the present invention. This storage shelf 1 depicted in FIG. 1 is installed in a semiconductor conveyance system of a semiconductor manufacturing plant, for example. The storage shelf 1 stores therein a front-opening unified pod (FOUP: wafer carrier) 100 (see FIG. 3) accommodating wafers. The FOUP 100 accommodates a plurality of wafers each preferably having a diameter of 300 millimeters or 450 millimeters, for example.

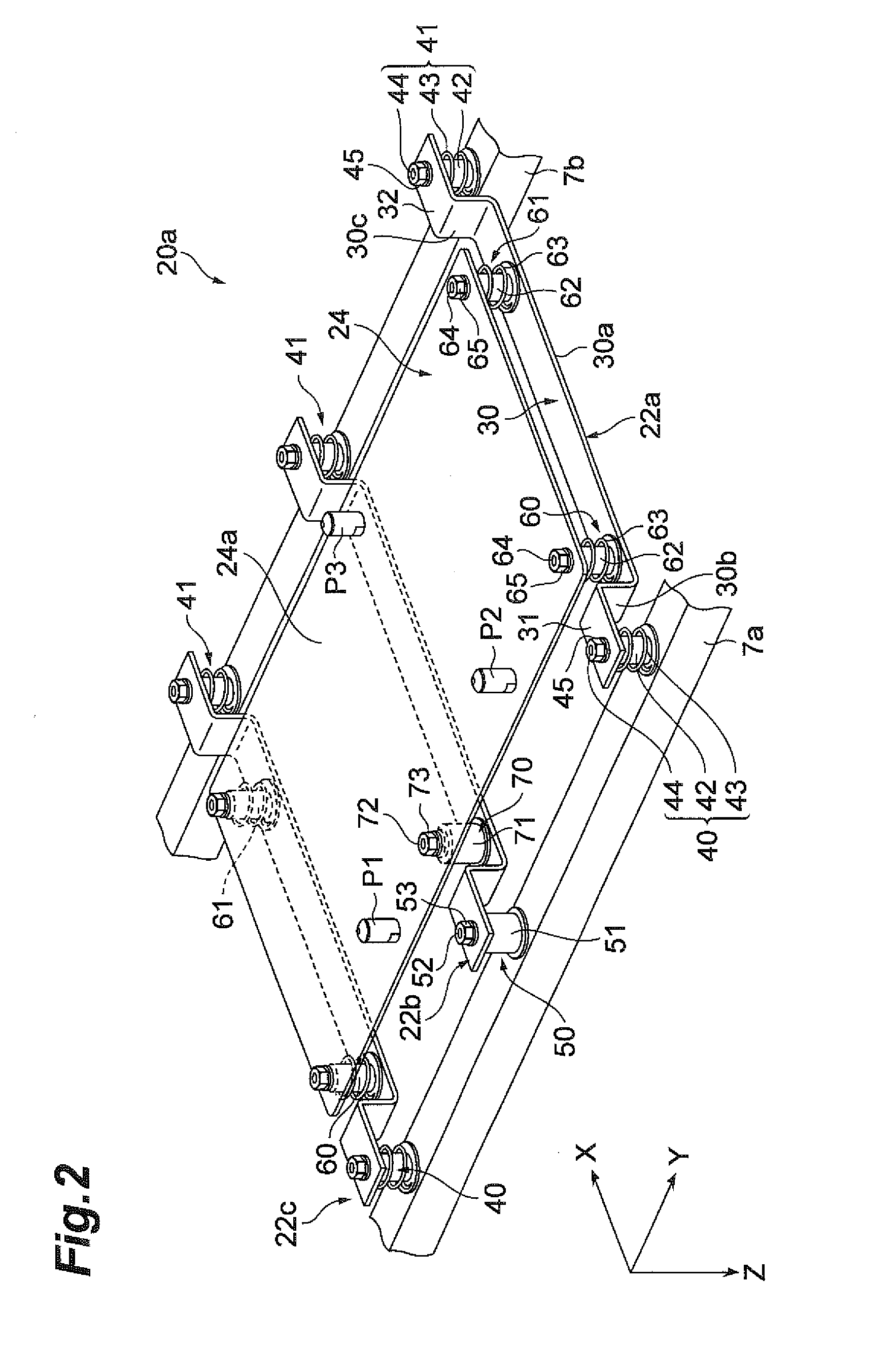

[0024]The storage shelf 1 includes a frame unit 10 and placement units 20a, 20b, 20c, and 20d. The frame unit 10 supports the placement units 20a to 20d. The frame unit 10 includes suspending members 3a, 3b, 3c, and 3d, connecting members 5a and 5b, and beam members 7a and 7b.

[0025]The suspending members 3a to 3d are pillar members extending in the vertical direction (Z-direction), provided in plurality (for example, preferably four in the present preferred embodime...

second preferred embodiment

[0055]A second preferred embodiment of the present invention will be described hereinafter. FIG. 5 is a side view of a storage shelf according to the second preferred embodiment. As depicted in FIG. 5, this storage shelf 1B includes the frame unit 10 and the placement unit 20a (20b, 20c, 20d (see FIG. 1)). The frame unit 10 supports the placement unit 20a (20b to 20d). The frame unit 10 includes the suspending members 3a to 3d (see FIG. 1), the connecting members 5a and 5b, and the beam members 7a and 7b.

[0056]The placement unit 20a includes a shelf plate 24A. The shelf plate 24A is a plate-shaped member having a rectangular or substantially rectangular shape, and the FOUP 100 is placed thereon. The shelf plate 24A has a width in the X-direction larger than the distance between the beam members 7a and 7b, and is arranged over the beam members 7a and 7b. The shelf plate 24A is arranged on the beam members 7a and 7b with the elastic bodies 80 and 81 interposed therebetween.

[0057]The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com