Three-shaft robot

A robot and robotic arm technology, applied in the field of three-axis robots, can solve problems such as large motion inertia, small application range, and large robot volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

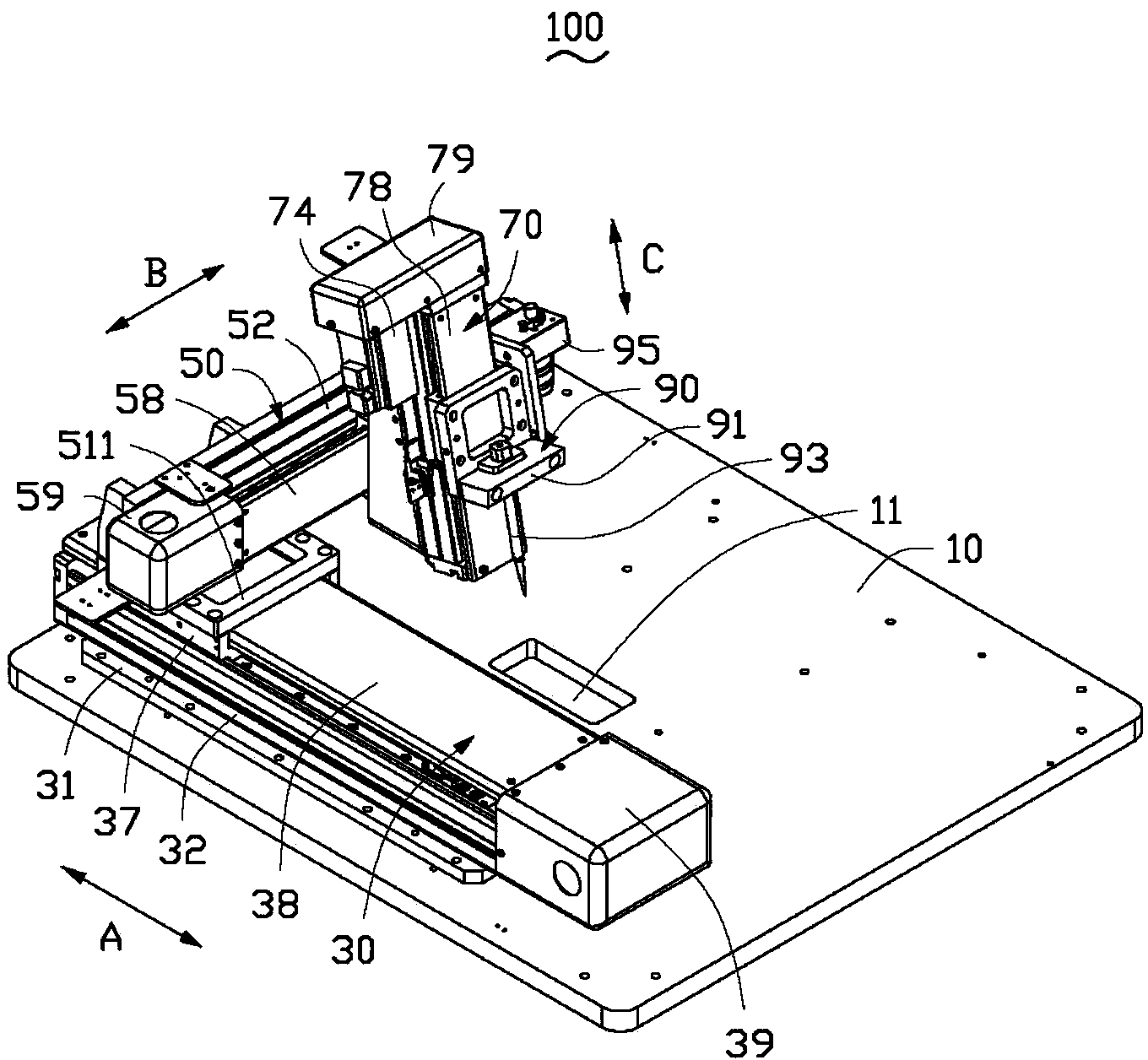

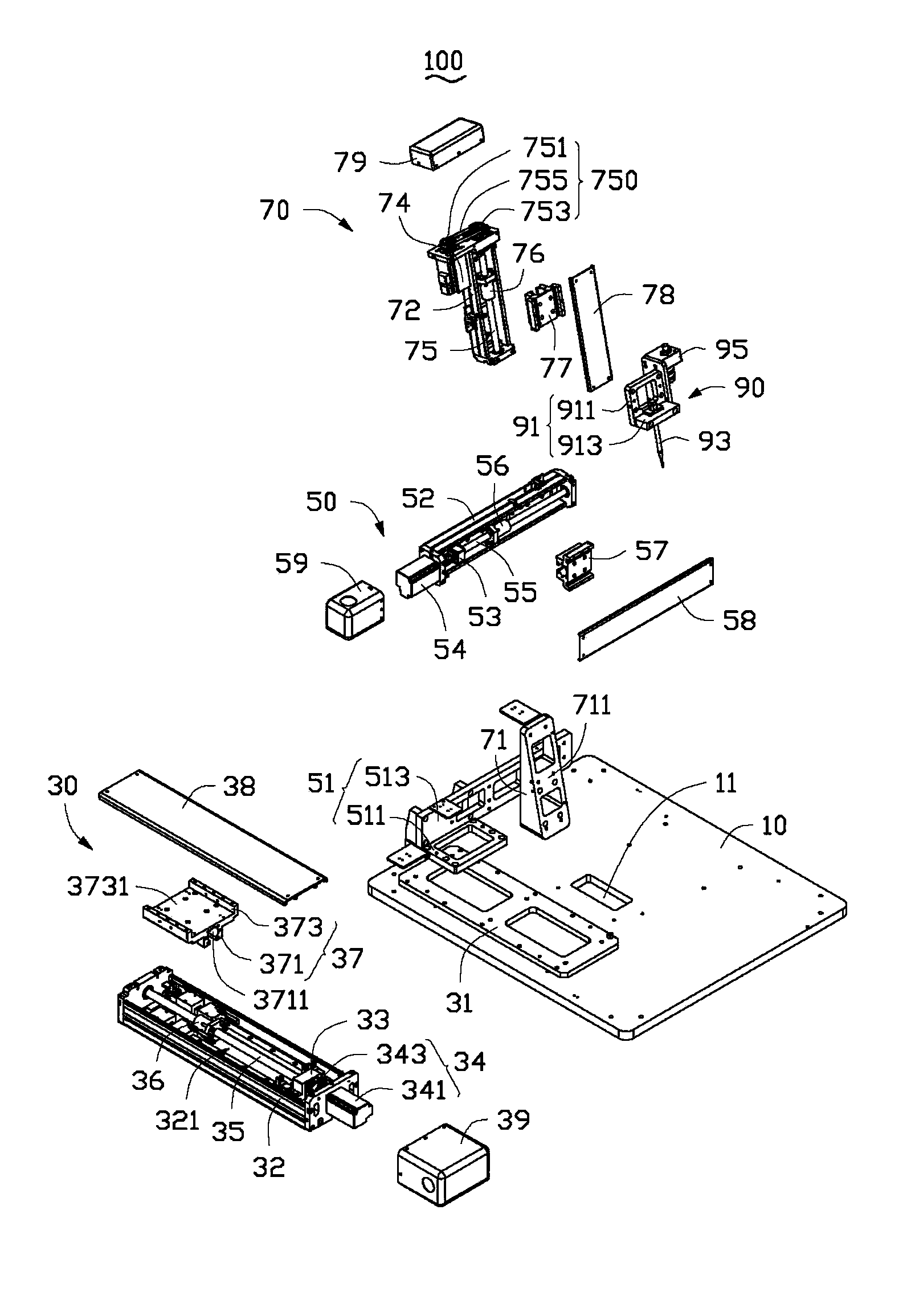

[0010] see figure 1 , the three-axis robot 100 according to the embodiment of the present invention includes a support platform 10 , a first robot arm 30 , a second robot arm 50 , a third robot arm 70 and an actuator 90 . The first mechanical arm 30 is installed on the support platform 10, the second mechanical arm 50 is installed on the first mechanical arm 30, the third mechanical arm 70 is installed on the second mechanical arm 50, and the actuator 90 is installed on the second mechanical arm 50. Three mechanical arms 70 on. The first mechanical arm 30 can drive the second mechanical arm 50 to slide along the first direction A, the second mechanical arm 50 can drive the third mechanical arm 70 to slide along the second direction B, and the third mechanical arm 70 can drive the actuator 90 Swipe along the third direction C. The moving direction C of the actuator 90 is oblique to the plane formed by the moving direction A of the second mechanical arm 50 and the moving direc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap