A radial tire building machine

A radial tire and molding machine technology, applied in the field of tire manufacturing, can solve the problems of low green tire output and large difference in utilization efficiency of forming drums, etc., and achieve the effect of improving molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The structure and principle of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

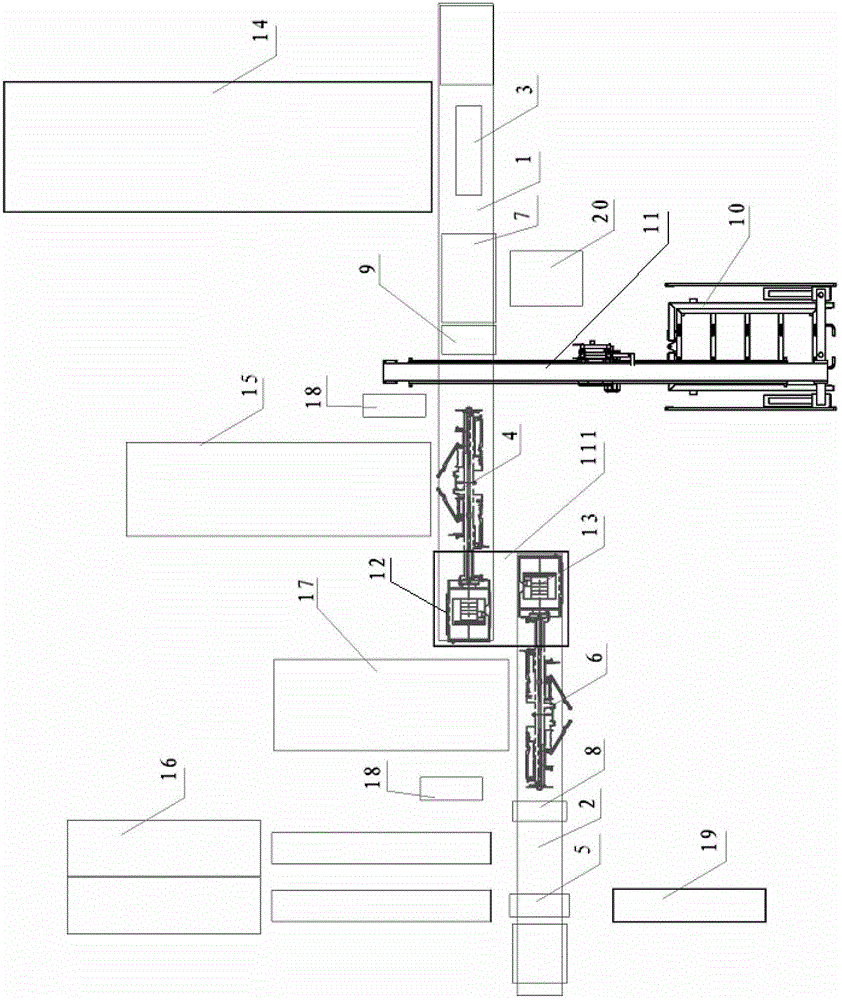

[0029] Such as figure 1 As shown, the present embodiment provides a radial tire building machine, including a bed, feed racks arranged on both sides of the bed, and the following on the bed:

[0030] The first fitting drum 3 for fitting the carcass assembly;

[0031] A second fitting drum 5 for fitting the tread assembly;

[0032] A first building drum 4 and a second building drum 6 for alternately completing the first process of releasing the last cycle of tires, receiving said carcass assembly, and applying mats thereon Glue, the second process is to receive the tread assembly, roll forming tires, the first forming drum 4 and the second forming drum 6 are arranged on the first laminating drum 3 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com