Pump station optimization operation method based on equipment full life cycle supervision

A full-life cycle, optimized operation technology, applied in complex mathematical operations, climate change adaptation, instruments, etc., can solve problems such as maintenance and replacement of difficult pump sets, drainage operations that cannot be optimized and adjusted in time, and reasonable arrangements for difficult drainage work, etc., to achieve Reduce errors, enhance practical value, and balance working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the preferred embodiments.

[0024] A pumping station optimization operation method based on the supervision of the whole life cycle of equipment, specifically as follows:

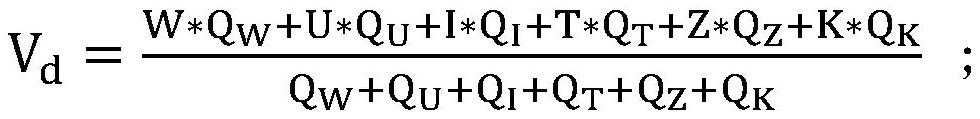

[0025] Select the evaluation objects of the pumping station and the evaluation indicators corresponding to each evaluation object. The selection criteria for the evaluation objects are the core work parts during the operation of the pump station. Among them, the core work parts include water pump units, assembled metal structures, technical water supply systems, For the excitation device and electrical equipment, in each evaluation object, select the parameter index that has a greater impact on the working conditions in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com