A kind of preparation method of p-phenylene benzobisoxazole-silsesquioxane copolymer

A technology of benzobisoxazole and silsesquioxane, which is applied in the field of chemistry, can solve the problems of reduced mechanical properties of materials, destruction of PBO structure, and difficulty in processing and molding, achieving fewer steps, lower requirements for experimental conditions, and excellent solubility and film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

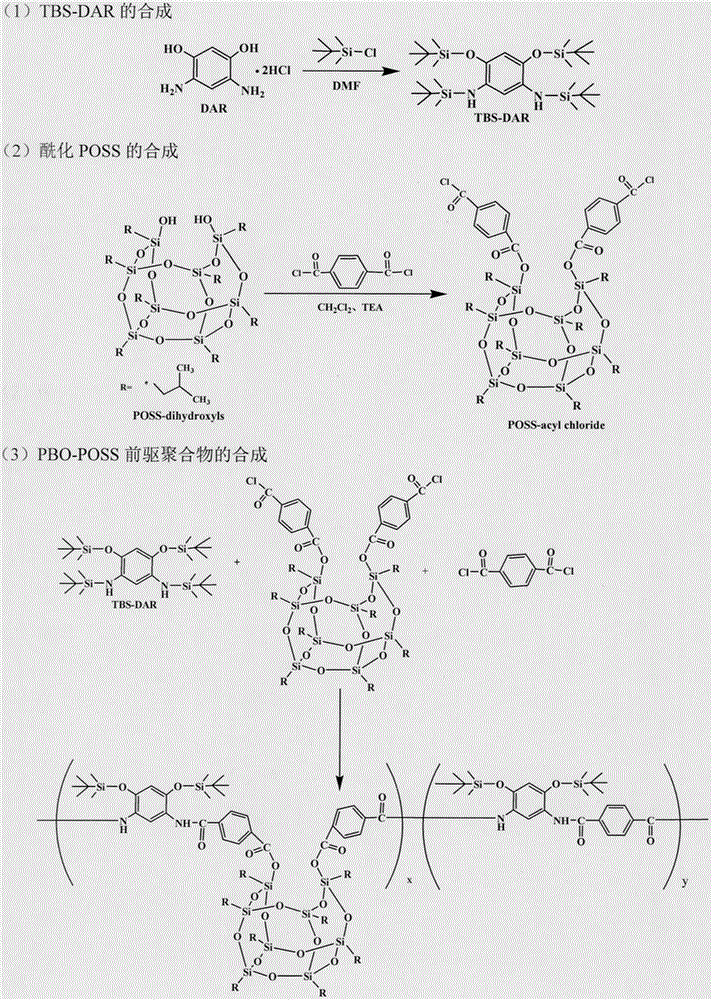

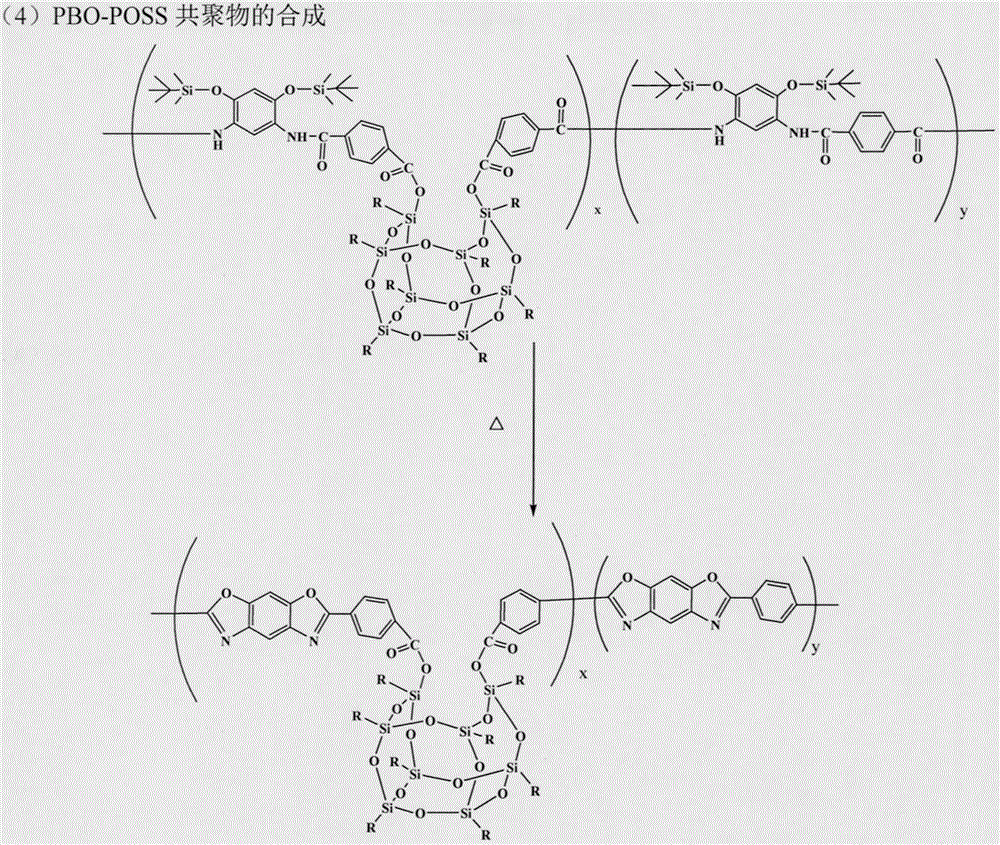

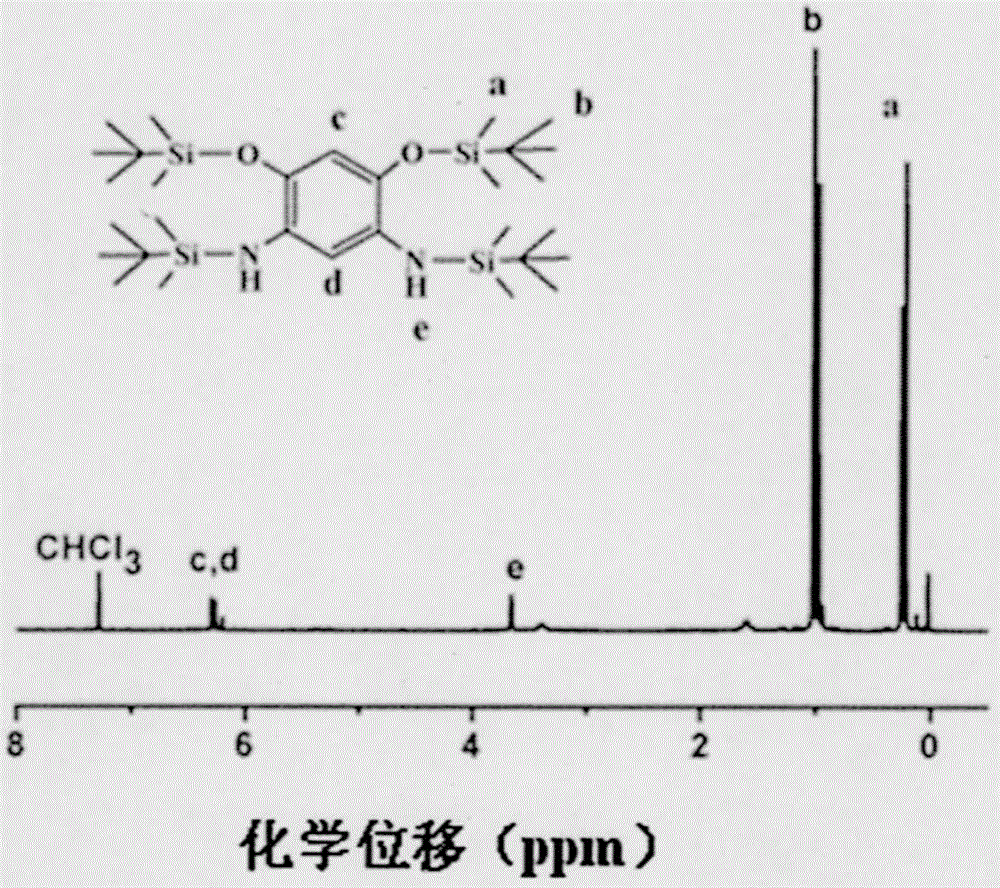

[0022] (1) Synthesis of TBS-DAR:

[0023] Add 2.13g 4,6-diaminoresorcinol dihydrochloride (DAR) and 100mL DMF into an anhydrous and oxygen-free Schlenk bottle with an air inlet and a magnetic stirring bar, and 7.50g tert-butyldimethyl Chlorochlorosilane (TBS) was dissolved in 100 mL of anhydrous DMF to make it completely dissolved. Under rapid stirring, the TBS solution and 27.3 g of the acid-binding agent triethylamine (TEA) were added dropwise into the above-mentioned Schlenk bottle respectively, and a brown-yellow suspension was formed after the addition was complete. Seal the reaction device and stir at room temperature for 12h. After the reaction was terminated, a yellow solid was obtained by suction filtration, washed with deionized water several times, and the obtained solid product was dried in a vacuum oven at 80° C. for 24 hours to prepare TBS-DAR.

[0024] (2) Preparation of acylated POSS:

[0025] Under argon protection, dissolve 5 g of terephthaloyl chloride in...

Embodiment 2

[0033] Note: In this patent, the preparation and heat treatment of TBS-DAR, acylated POSS and PBO-POSS precursor polymer films are consistent with those described in Example 1. In the following examples, only functionalized PBO-POSS precursor polymers are introduced. preparation.

[0034] Preparation of functionalized PBO-POSS precursor polymer 2:

[0035] Under the protection of argon, TBS-DAR (0.597g, 1.0mmol) and 5mL N-methylpyrrolidone (NMP) were added dropwise into the Schlenk tube, and the acylated POSS (0.6125g, 0.5mmol) and terephthaloyl chloride (0.1020 g, 0.5mmol) was dissolved in 5mL NMP and added dropwise to the Schlenk tube. Seal the reaction device and stir at 30°C for 24h. After the reaction, the obtained wine-red liquid was added dropwise to 200mL deionized water to obtain gray-black precipitate, which was washed several times with deionized water, filtered with suction, and dried in a vacuum oven at 80°C for 24 hours to obtain PBO-POSS precursor polymer 2 ....

Embodiment 3

[0037] Preparation of functionalized PBO-POSS precursor polymer 3:

[0038] Under the protection of argon, TBS-DAR (0.597g, 1.0mmol) and 5mL N-methylpyrrolidone (NMP) were added dropwise into the Schlenk tube, and the acylated POSS (0.2450g, 0.2mmol) and terephthaloyl chloride (0.1630 g, 0.8mmol) was dissolved in 5mL NMP and added dropwise to the Schlenk tube. Seal the reaction device and stir at 30°C for 24h. After the reaction, the obtained wine-red liquid was added dropwise to 200mL deionized water to obtain gray-black precipitate, which was washed several times with deionized water, filtered with suction, and dried in a vacuum oven at 80°C for 24 hours to obtain PBO-POSS precursor polymer 3 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap