Preparation and application of a zinc hydroxystannate-palygorskite-mercaptan composite flame retardant

A technology of zinc hydroxystannate and composite flame retardant, which is applied in the field of composite flame retardants, can solve the problems of composite material damage to mechanical properties, low cost performance of flame retardancy, and large crystal particle size, so as to increase the degree of crosslinking and enhance mechanical properties. performance, the effect of expanding the range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

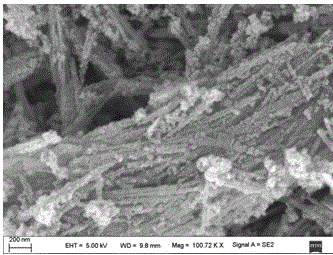

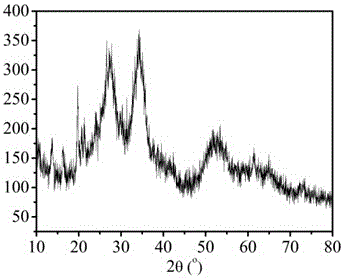

[0031] (1) Preparation of composite flame retardant: Weigh 3g palygorskite clay and disperse it in 100mL ethanol to form palygorskite / ethanol solution; 0.6g zinc chloride (dissolved in 30mL water) and 1.5g tin chloride (dissolved in Add palygorskite / ethanol solution in 30mL water) and stir vigorously to make it evenly mixed; then add potassium hydroxide solution (0.6g, dissolved in 40mL water), continue to stir vigorously for 2h, then move to the hydrothermal reaction kettle, React at 100°C for 10 hours; after the reaction, the precipitate was centrifuged, washed with water and ethanol in turn, and then dried to obtain the zinc hydroxystannate-palygorskite composite; finally, zinc hydroxystannate-palygorskite clay was mixed with commercially available 2- Amino-1,3,5-triazine-4,6-dithiol is compounded at a mass ratio of 10:1 to obtain a zinc hydroxystannate-palysol-thiol composite flame retardant;

[0032] (2) Preparation of flame-retardant polypropylene: Add the zinc hydroxyst...

Embodiment 2

[0035](1) Preparation of composite flame retardant: Weigh 3g palygorskite clay and disperse it in 100mL ethanol to form palygorskite / ethanol solution; 0.15g zinc chloride (dissolved in 30mL water) and 0.2 g tin chloride (dissolved in Add palygorskite / ethanol solution in 30mL water) and stir vigorously to make it evenly mixed; then add potassium hydroxide solution (0.3 g dissolved in 40mL water), continue to stir vigorously for 5h, then move to the hydrothermal reaction kettle, at 140 ℃ for 24 hours; after the reaction, the precipitate was centrifuged, washed with water and ethanol in turn, and then dried to obtain the zinc hydroxystannate-palygorskite composite; finally, the zinc hydroxystannate-palygorskite clay was combined with the commercially available 2-amino -1,3,5-triazine-4,6-dithiol is compounded at a mass ratio of 100:1 to obtain a zinc hydroxystannate-palyllone-thiol composite flame retardant;

[0036] (2) Preparation of flame-retardant polypropylene: Add the zinc ...

Embodiment 3

[0039] (1) Preparation of composite flame retardant: Weigh 3g palygorskite clay and disperse in 100mL ethanol to form palygorskite / ethanol solution; 0.5g zinc chloride (dissolved in 30mL water) and 1.0g tin chloride (dissolved in Add palygorskite / ethanol solution in 30mL water) and stir vigorously to make it evenly mixed; then add potassium hydroxide solution (0.4g, dissolved in 40mL water), continue to stir vigorously for 4h, then move to the hydrothermal reaction kettle, React at 120°C for 15 hours; after the reaction, the precipitate was centrifuged, washed with water and ethanol in turn, and then dried to obtain the zinc hydroxystannate-palygorskite composite; finally, the zinc hydroxystannate-palygorskite clay was mixed with the commercially available 2- Amino-1,3,5-triazine-4,6-dithiol is compounded at a mass ratio of 60:1 to obtain a zinc hydroxystannate-palysol-thiol composite flame retardant;

[0040] (2) Preparation of flame-retardant polypropylene: Add the zinc hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com