Coal-blending and coke-making method involved with low G value 1/3 coking coal

A coal blending coking and G value technology, applied in the coking oven, petroleum industry, etc., can solve the problems of different classification indexes and low blending amount, and achieve the effect of reducing the cost of coal blending

Active Publication Date: 2014-11-12

武汉钢铁有限公司

View PDF7 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are many sorting and blending technologies for 1 / 3 coking coal, but the classification indicators are different, and the blending amount is relatively low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

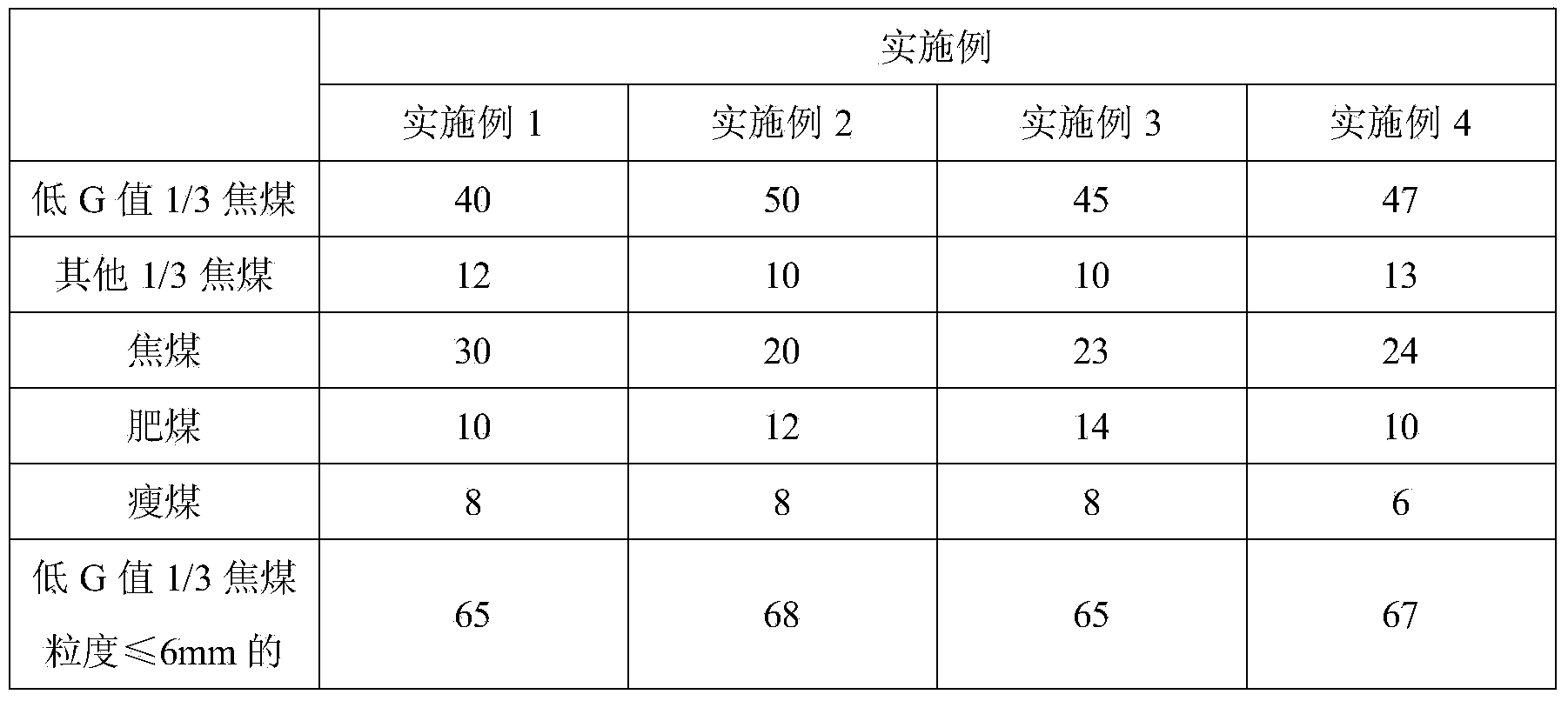

[0019] Specific examples are shown in Table 1 below.

[0020] Table 1 Coal blending schemes of Examples 1 to 4 and the CRI and CSR values of the coke made in each example

[0021]

[0022]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| cohesion index | aaaaa | aaaaa |

| cohesion index | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a coal-blending and coke-making method involved with low G value 1 / 3 coking coal. The G value of the low G value 1 / 3 coking coal is smaller than 75, the volatile component Vdaf is greater than 34%, and the coking coal of which the particle size is smaller than or equal to 6mm accounts for greater than or equal to 65wt%. The coal-blending and coke-making method comprises the following steps: 1) determining single coking coal and the weight percent thereof in blended coal; 2) controlling the moisture of the blended coal at 3-4%; 3) carrying out primary screening on the blended coal, collecting pulverized coal below the sieve, carrying out secondary screening when the blended coal on the sieve, which is crushed into particles with the particle size of smaller than 3mm, accounts for 70-75wt%, and mixing the pulverized coal below the sieve in two steps to obtain screened and mixed pulverized coal; and 4) mixing the screened and pulverized coal with the secondarily screened pulverized coal on the sieve after pressing the screened and pulverized coal into balls, charging and coking the mixture. According to the method disclosed by the invention, the preparation amount of inferior 1 / 3 coking coal is increased, the coal blending cost is reduced, and the coal-blending and coke-making method has the functions of energy conservation, emission reduction and consumption reduction.

Description

technical field [0001] The invention belongs to the technical field of coking coal blending, and in particular relates to a coal blending coking method involving low G value 1 / 3 coking coal. Background technique [0002] According to China's coal classification standard GB / T5751-2009, the index requirement for 1 / 3 coking coal is V daf >28-37%, cohesion index G value>65, colloid layer thickness Y value≤25mm. According to the requirements of the above classification indicators, 1 / 3 coking coal can reach G value from >65 to >85 under the condition of satisfying the volatile content and Y value. Within this range, the caking properties of coking coal vary considerably, which will also have a significant impact on the quality of coke. In addition, 1 / 3 coking coal is one of the coking coals with a relatively high output of coking raw coal in my country. The rational use of 1 / 3 coking coal has a far-reaching impact on the protection of coking coal resources in my coun...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10B57/04

Inventor 张雪红项茹薛改凤徐功名鲍俊芳宋子逵任玉明詹立志陈鹏陈细涛

Owner 武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com