automatic washing machine

A technology of a fully automatic washing machine and a driving device, applied in the field of washing machines, can solve the problems of high cost, short service life, complicated structure of the electromagnetic clutch built in the motor, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

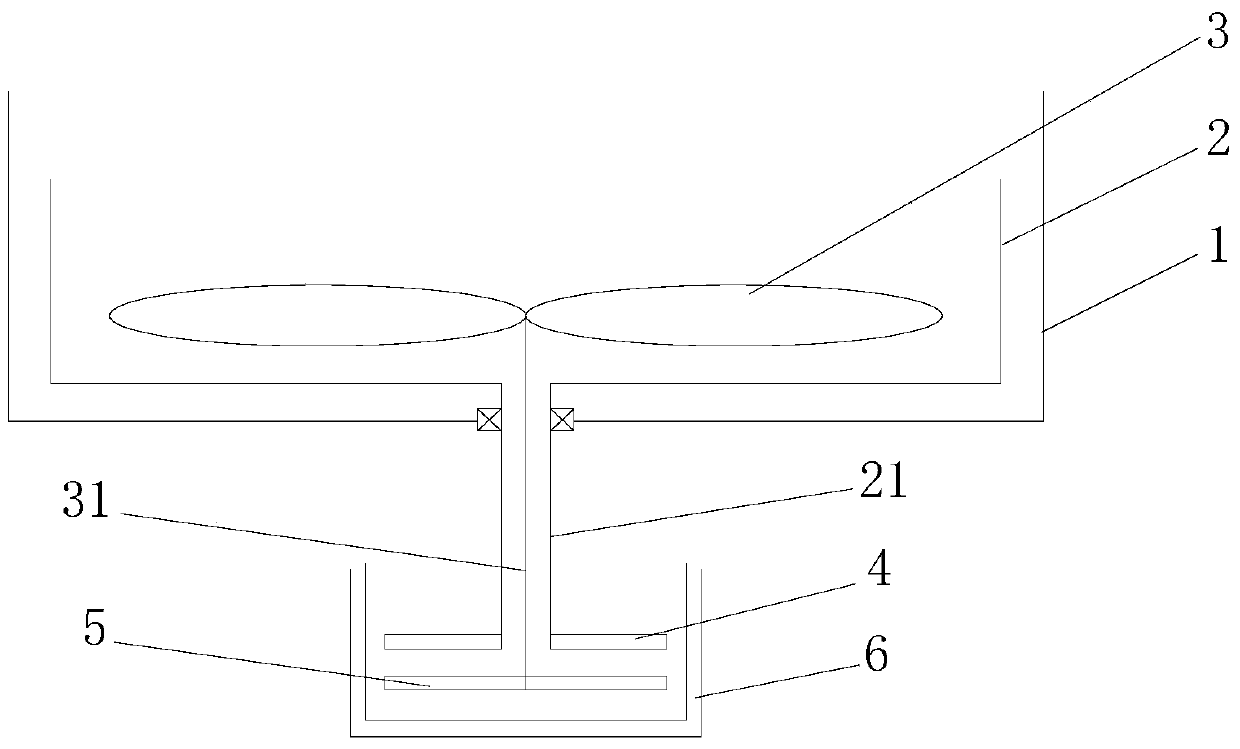

[0038] Such as figure 1 As shown, in this embodiment, the drive device is two rotors and a stator, respectively the first rotor 4, the second rotor 5 and the stator 6, the first rotor 4 and the second rotor 5 are both inner rotors, The stator 6 is the outer stator, the pulsator shaft 31 is coaxially arranged in the inner barrel shaft 21, the first rotor 4 is connected to the inner barrel shaft 21, the second rotor 5 is connected to the pulsator shaft 31, and the stator is fixed under the outer barrel through a mounting plate (in the figure not shown).

[0039] The washing machine in this embodiment is a dual-power washing machine, that is, the first rotor 4 and the second rotor 5 are controlled to drive the pulsator 3 and the inner tub 2 to rotate at different or the same speeds in opposite directions during washing, and to drive the pulsator 3 during dehydration. Rotate in the same direction and at the same speed as the inner barrel 2.

Embodiment 2

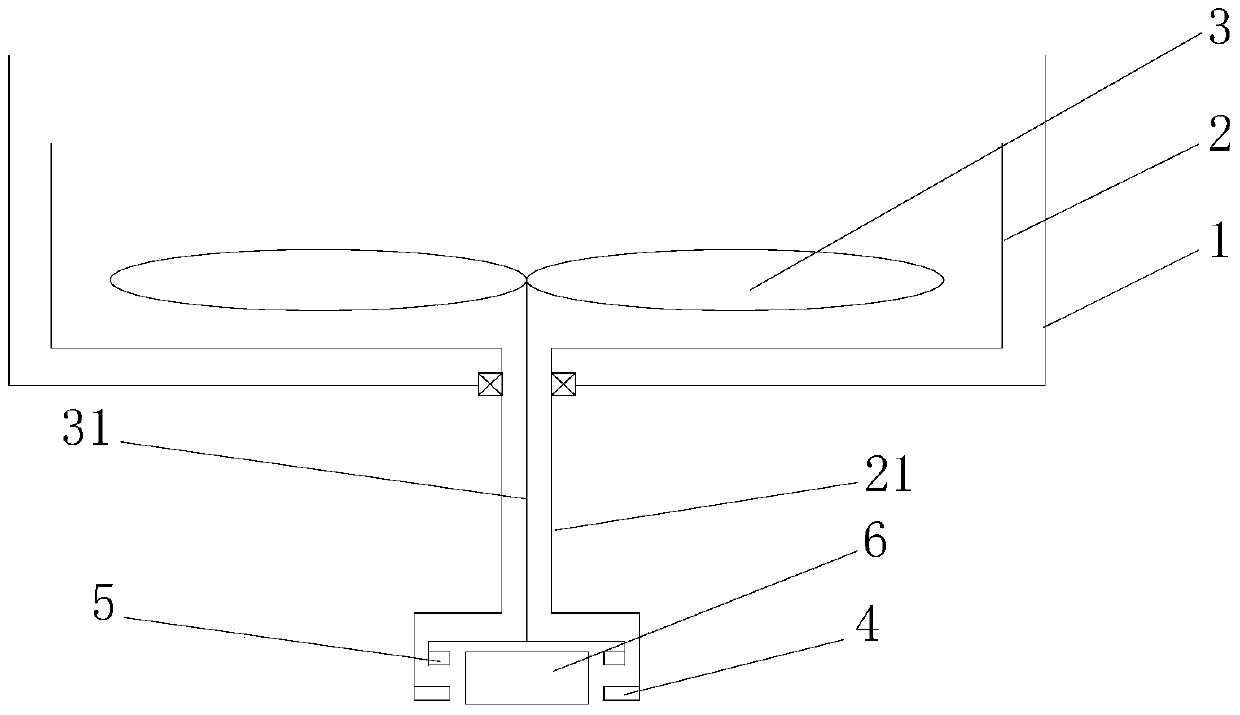

[0041] Such as figure 2 As shown, the difference between this embodiment and the first embodiment is that the first rotor 4 and the second rotor 5 are both outer rotors, and the stator 6 is an inner stator.

[0042] In the washing machine in this embodiment, the first rotor 4 and the second rotor 5 are controlled to drive the pulsator 3 and the inner tub 2 to rotate in the same direction and at different speeds respectively during washing, and to drive the pulsator 3 and the inner tub 2 to rotate in the same direction and at the same speed during dehydration.

Embodiment 3

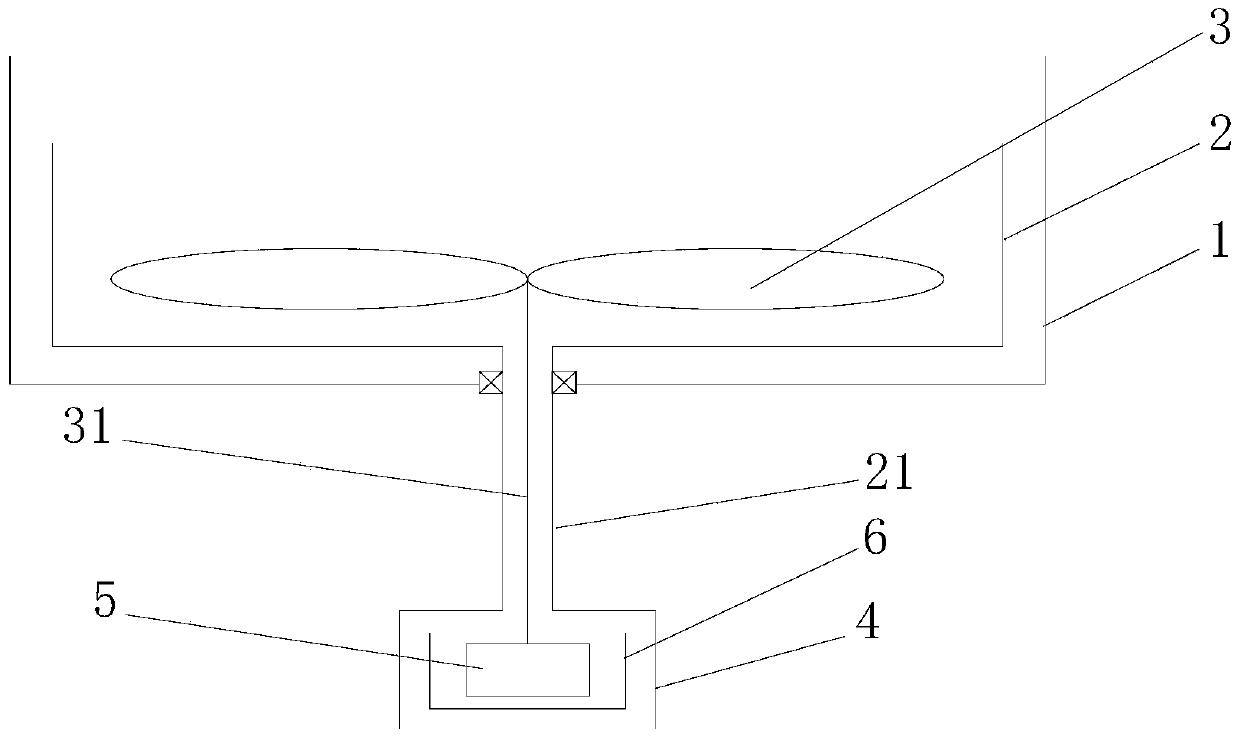

[0044] Such as image 3As shown, in the present embodiment, among the two rotors, the first rotor 4 is an outer rotor, the second rotor 5 is an inner rotor, the stator 6 is arranged between the first rotor 4 and the second rotor 5, and the pulsator shaft 31 Coaxially arranged in the inner barrel shaft 21 , the first rotor 4 is connected to the inner barrel shaft 21 , and the second rotor 5 is connected to the pulsator shaft 31 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com