Patents

Literature

36results about How to "Reduce intermediate loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

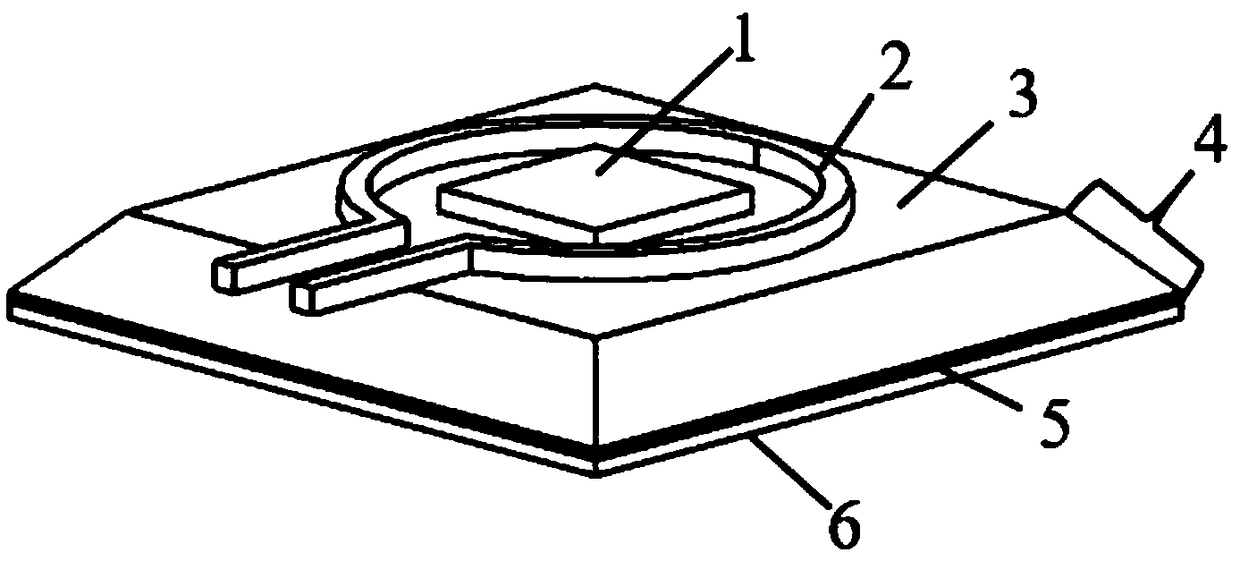

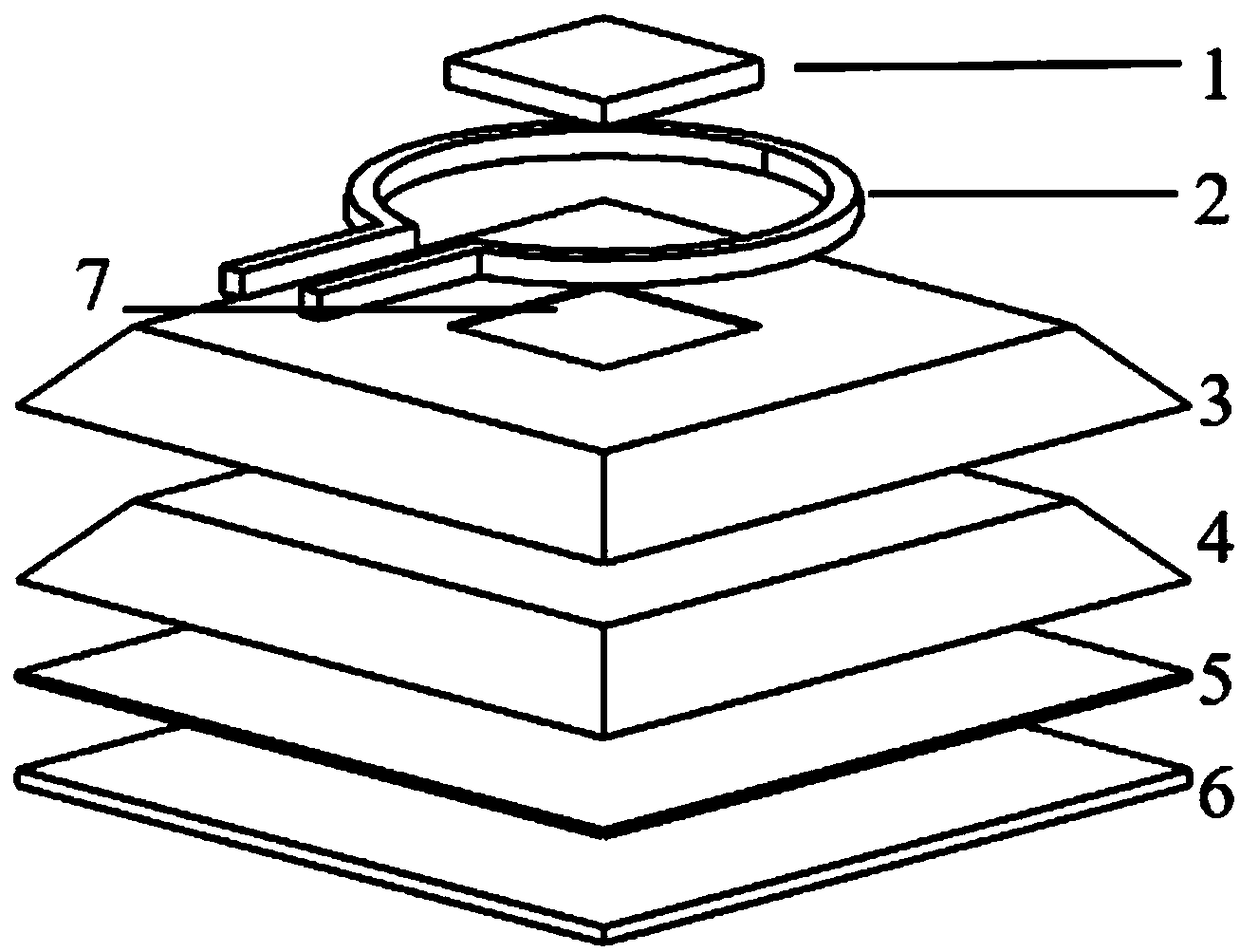

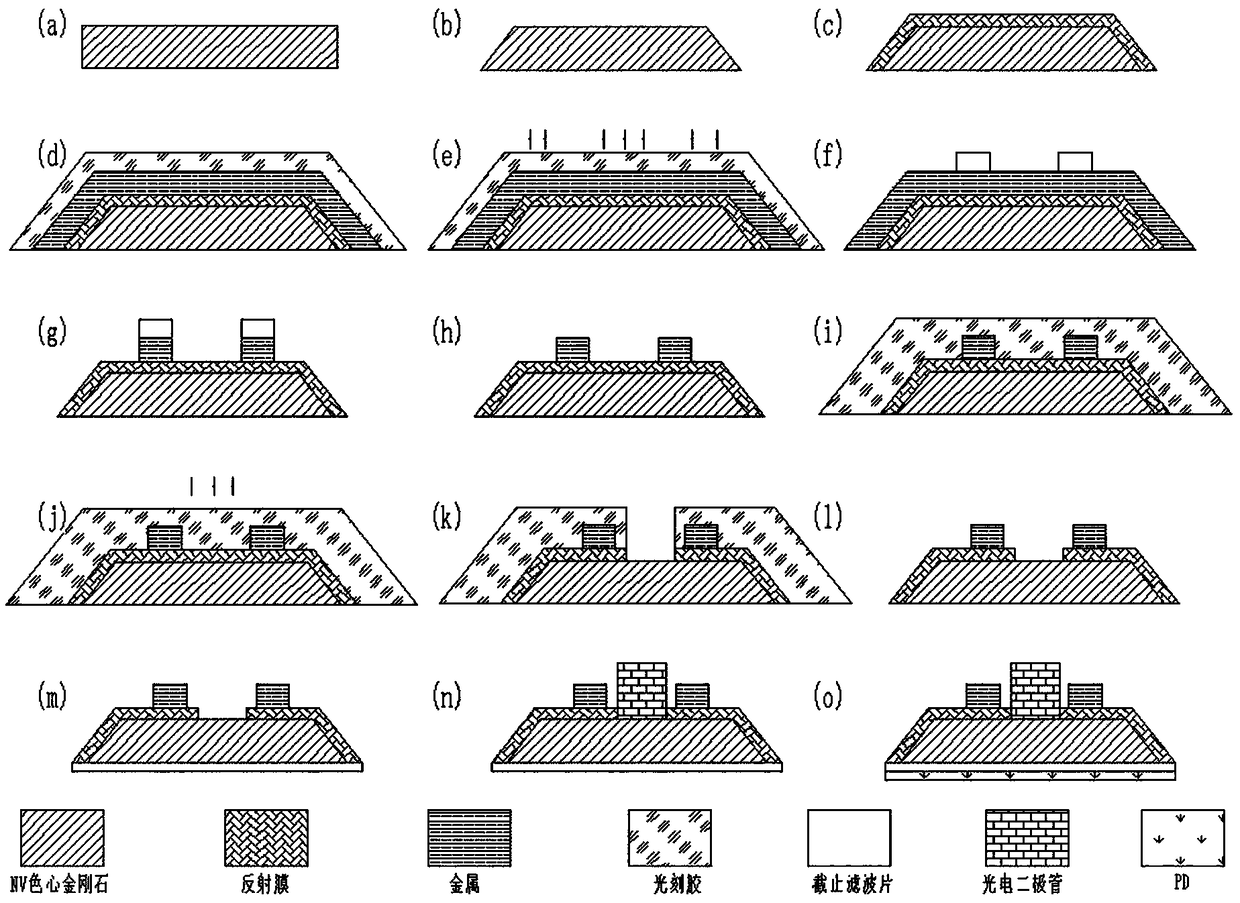

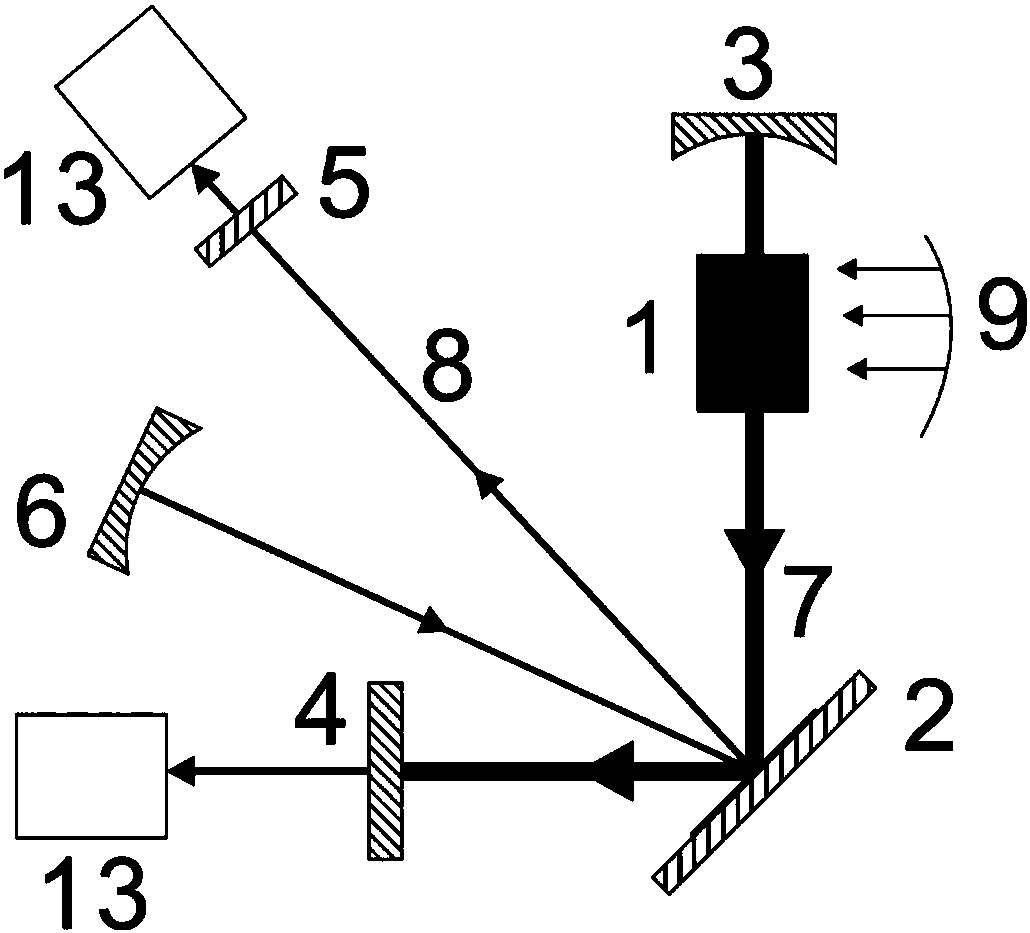

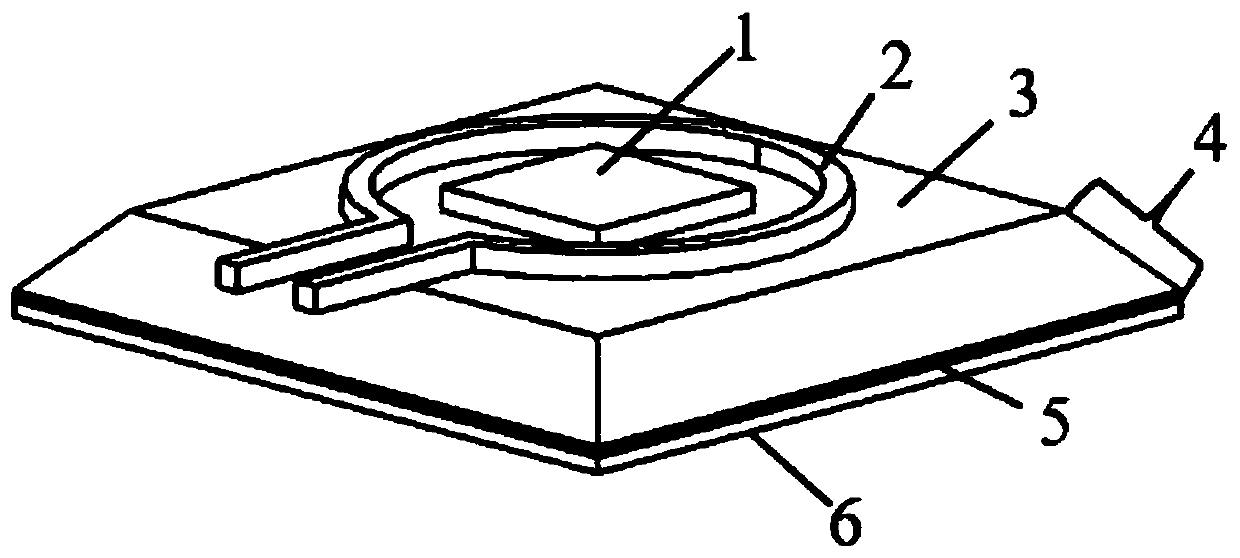

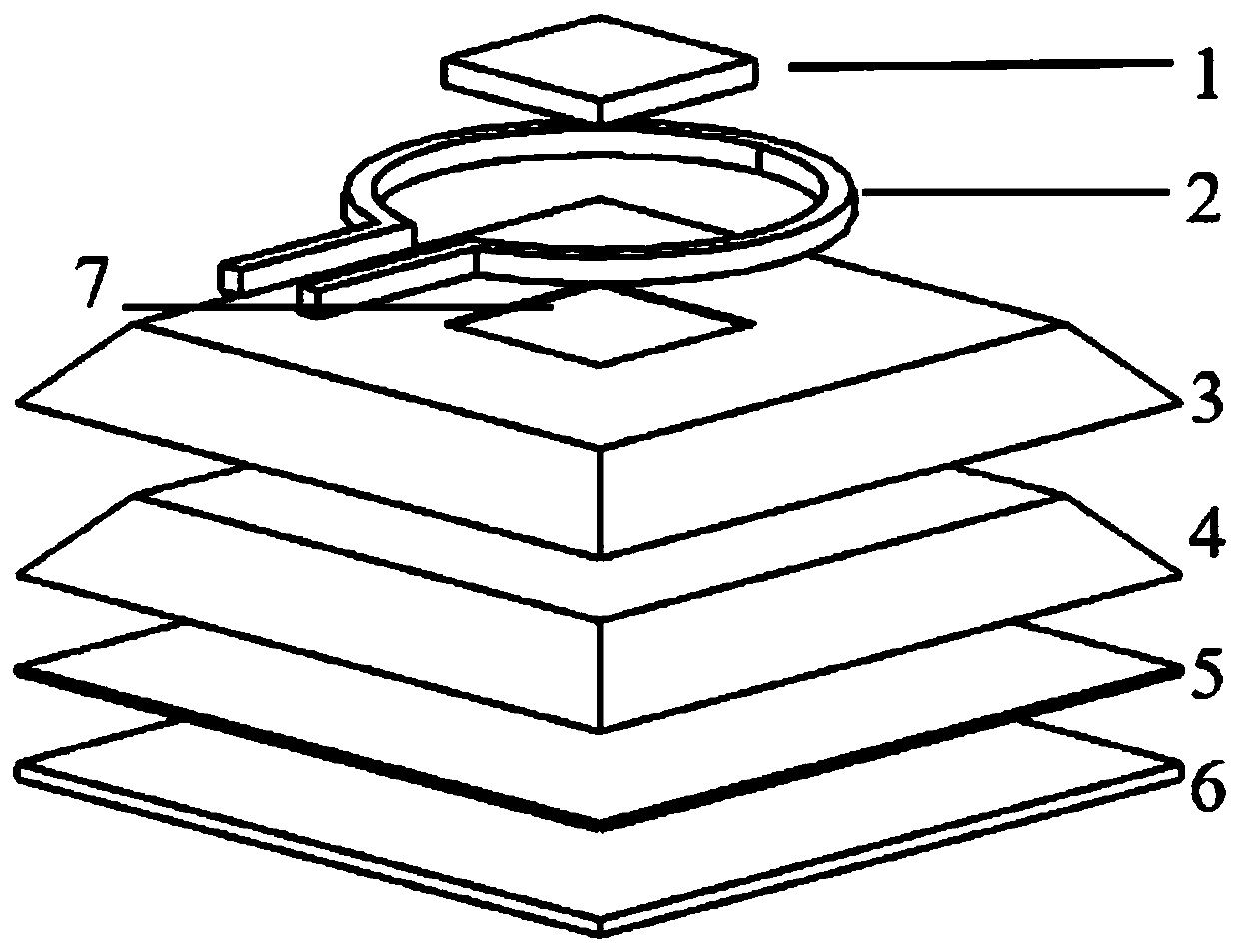

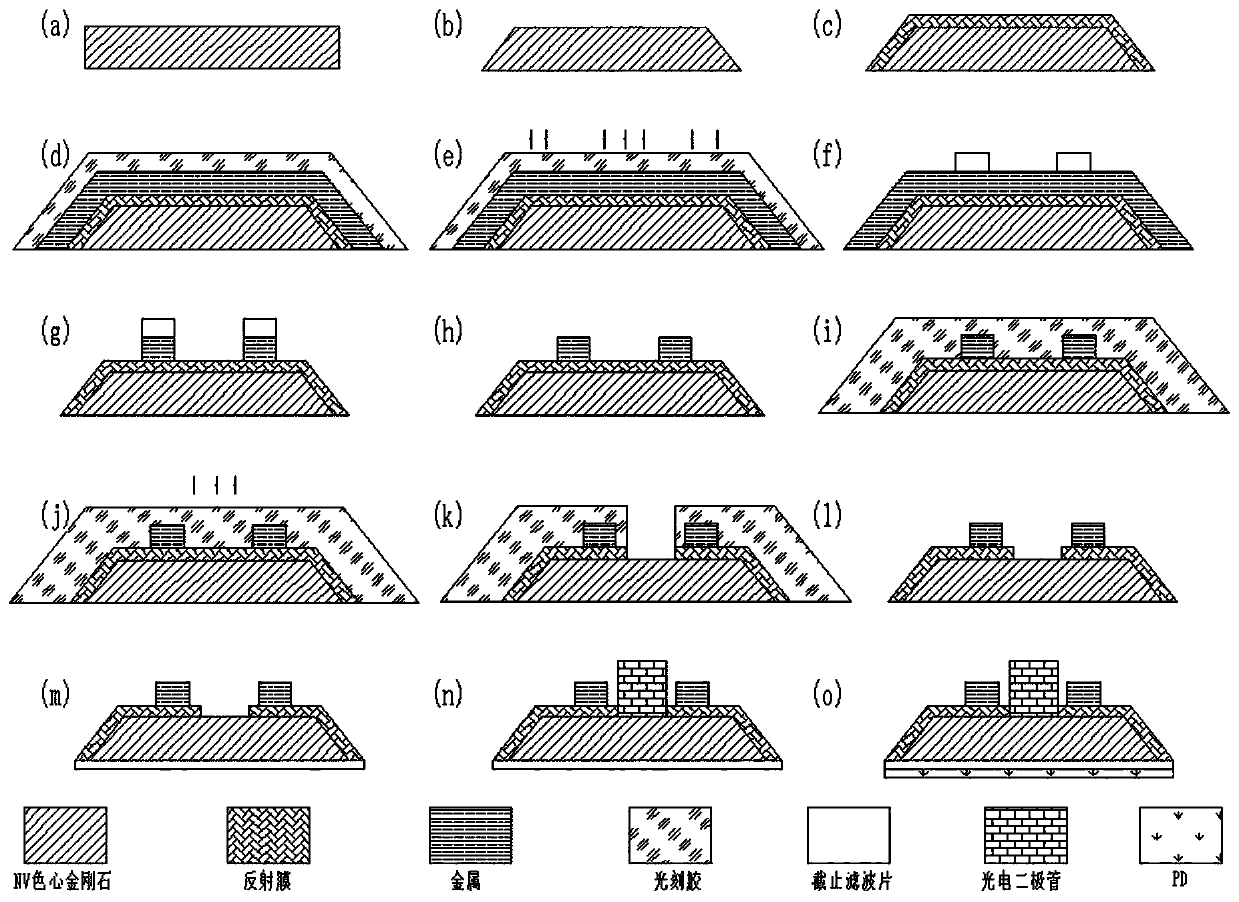

ODMR functional part integrated diamond NV magnetometer and manufacturing technology thereof

ActiveCN108983121AFor maximum integrationEfficient collectionMagnitude/direction of magnetic fieldsMicro nanoManufacturing technology

The invention discloses an ODMR functional part integrated diamond NV magnetometer and a manufacturing technology thereof, and belongs to the fields of solid state atom magnetometers and micro nano processing. A block-shaped diamond prepared with an NV color center ensemble is edged and shaped into a step-shaped diamond, a multi-layer medium combined reflective film is prepared in the upper surface of the diamond in a film growth technology, a multi-layer medium combined cutoff filtering film is prepared in the bottom, the two types of optical functional films wrap a diamond medium to form a light tripping structure, an annular microwave antenna is prepared on the light tripping structure with the diamond as the main body, a light through hole is cut, a laser diode and a photodiode are microfabricated, and the integrated NV magnetometer is realized. The total light tripping cavity structure and system modulation photon collecting functional parts are designed by taking the diamond as the core, the sensitivity of the solid atom magnetometer can be maximized, and the size of the device is reduced.

Owner:ZHONGBEI UNIV

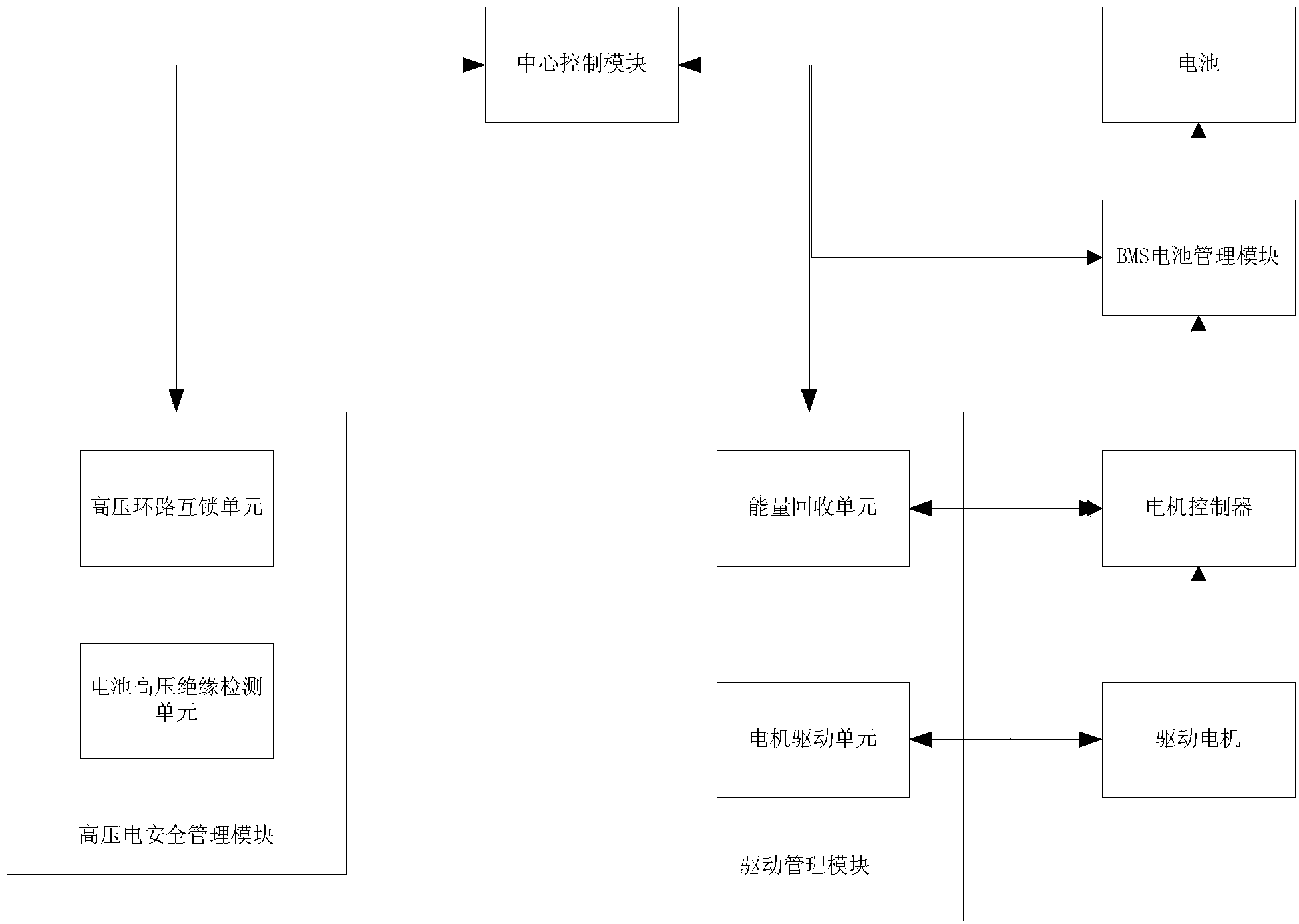

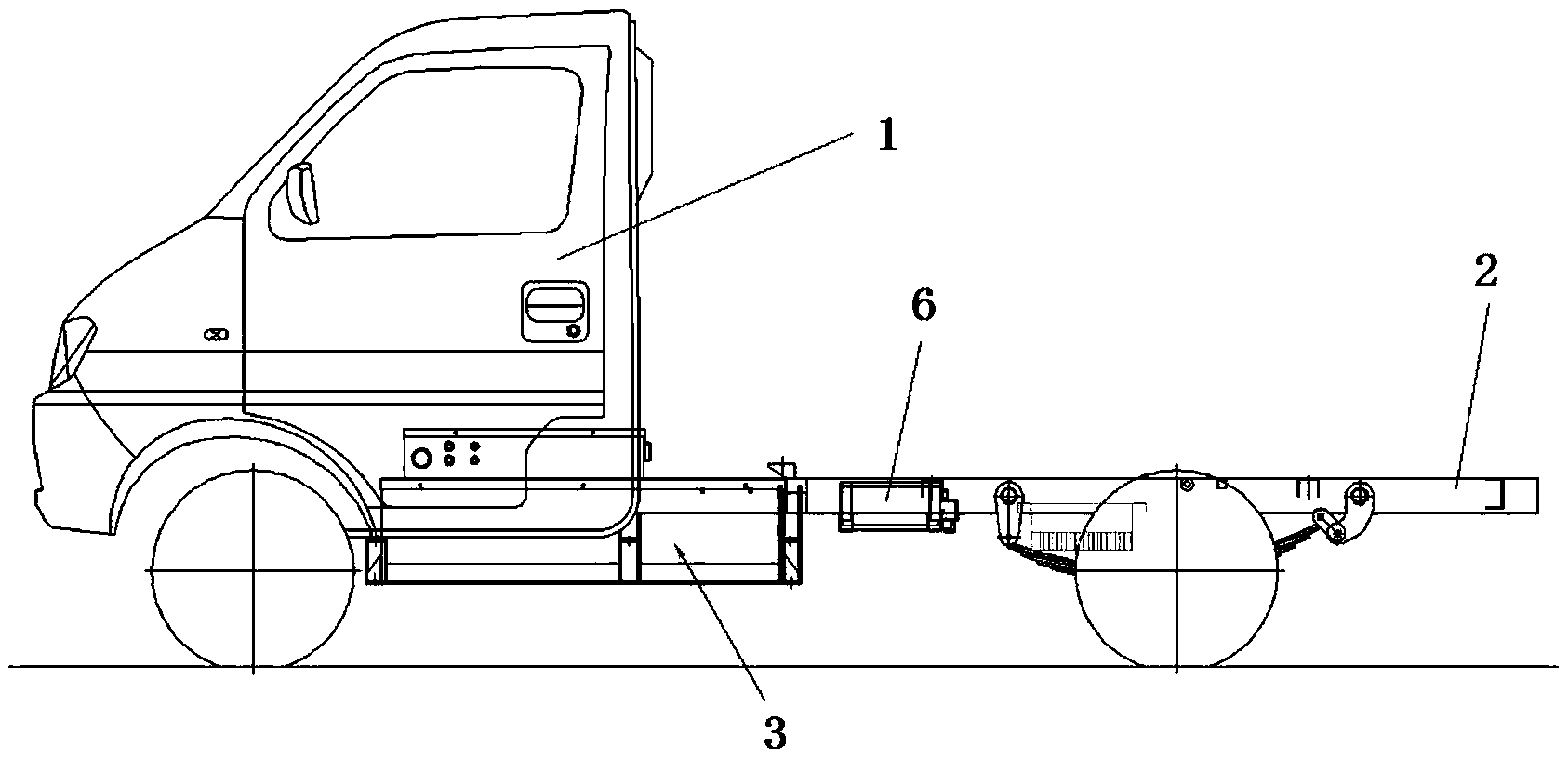

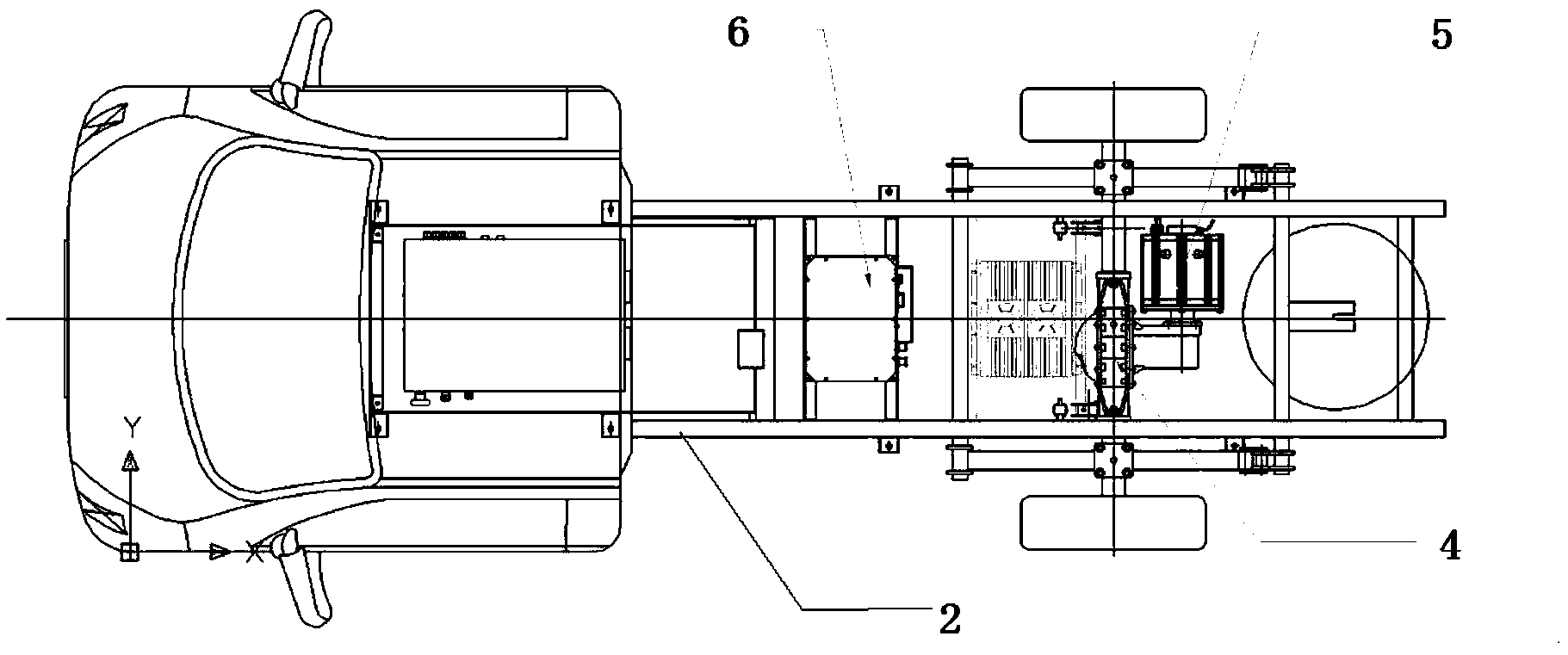

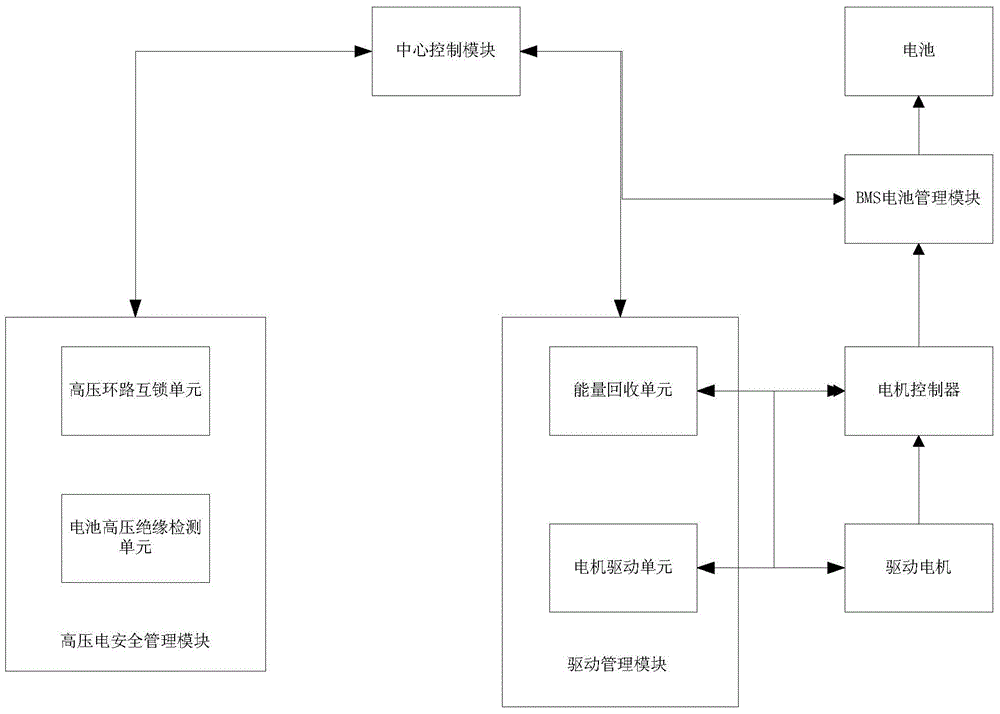

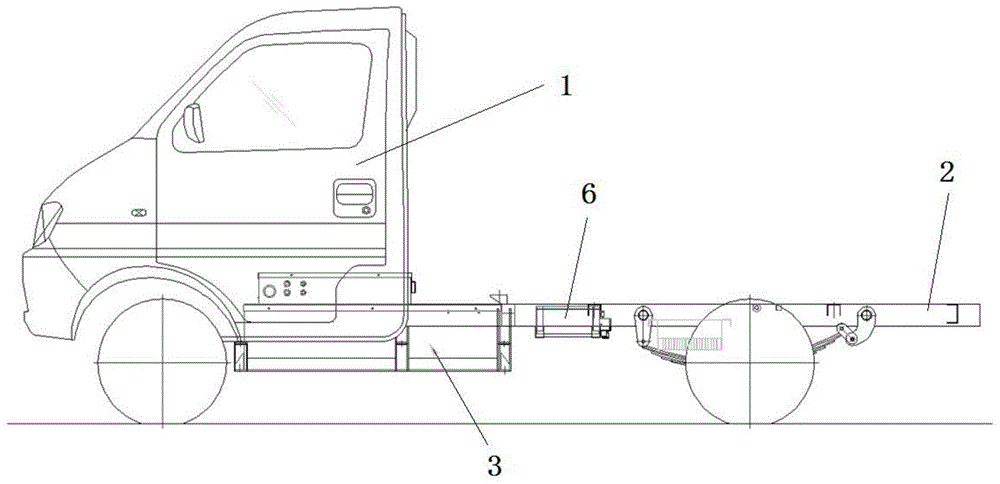

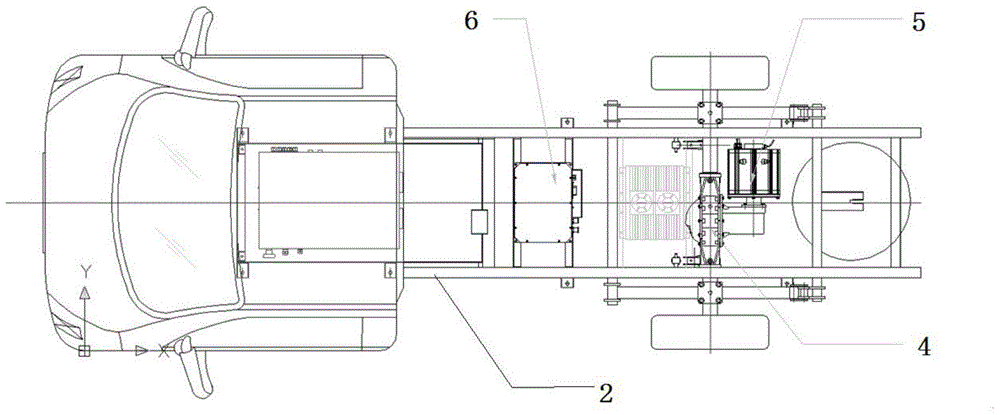

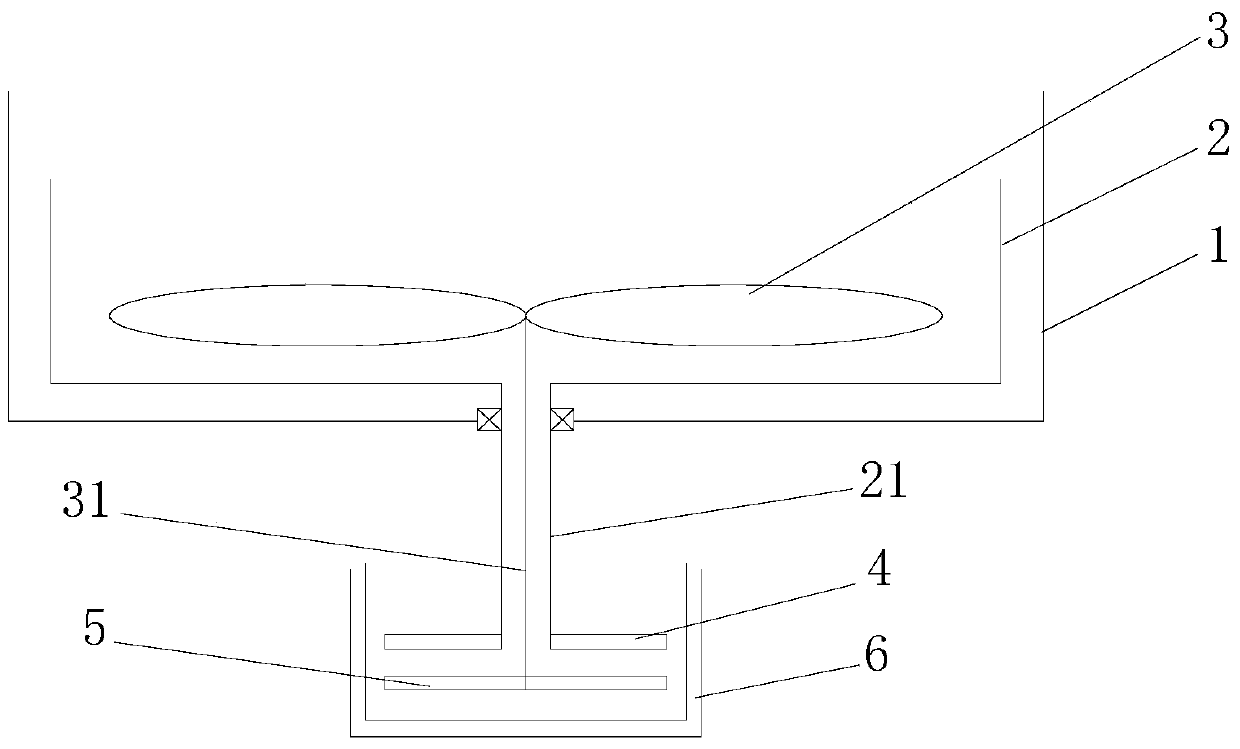

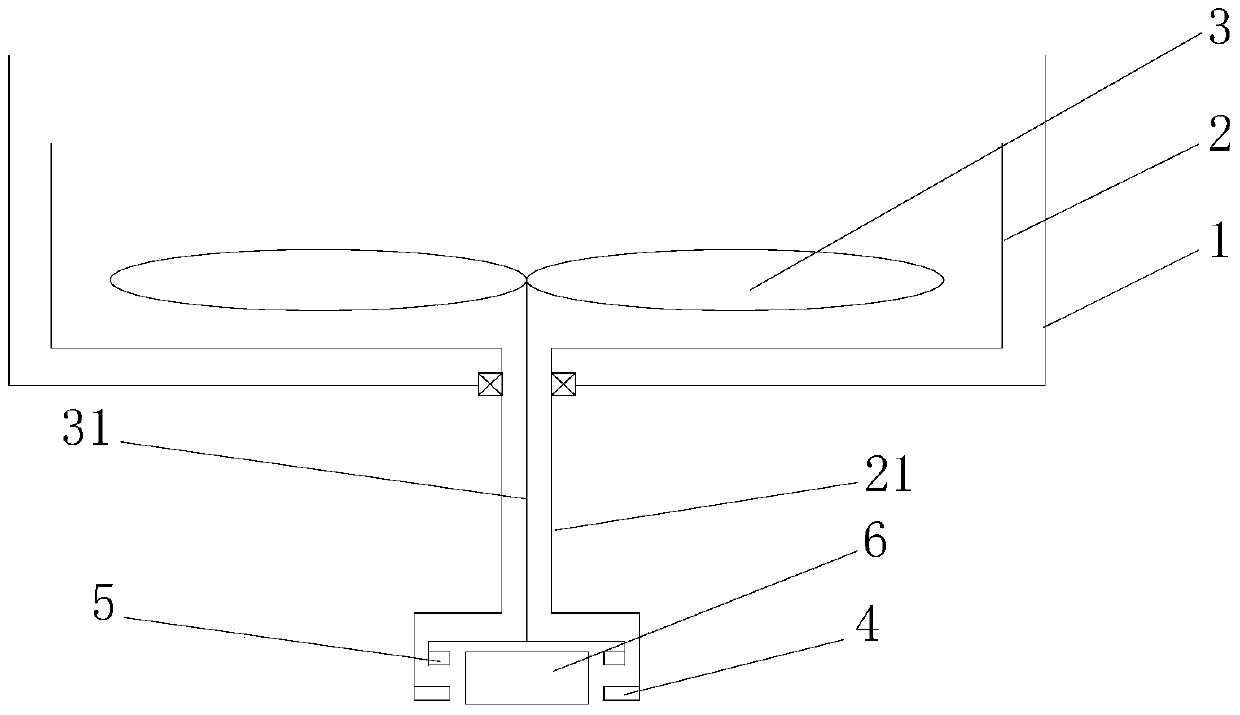

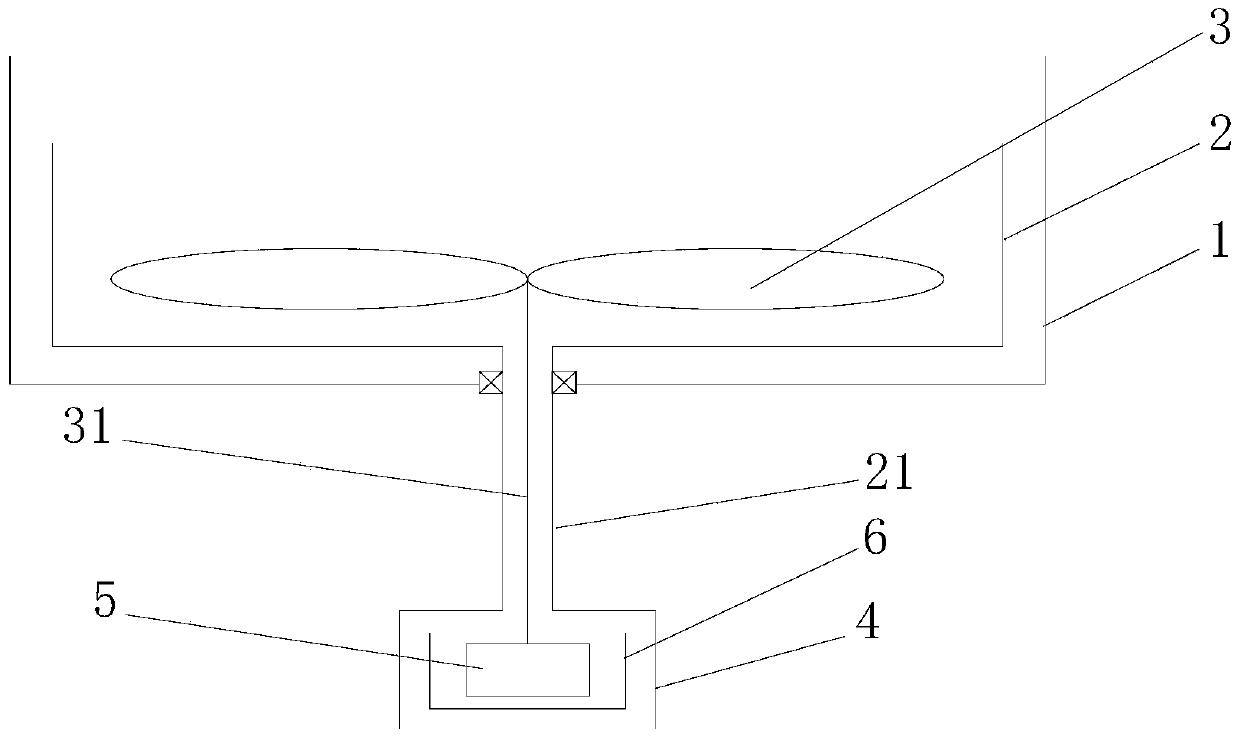

Vehicle control system of blade electric vehicle and blade electric vehicle structure

InactiveCN104015623AImprove battery lifeEasy to use electricitySpeed controllerElectric devicesElectricityControl system

The invention discloses a vehicle control system of a blade electric vehicle and a blade electric vehicle structure. A battery high-voltage insulation detection unit and a high-voltage loop interlocking unit are introduced into a high-voltage safety management module, and a vacuum brake assisting module is set, so that the electricity consumption and safety properties of the vehicle are largely improved. An energy recovery unit is implanted in a drive management system, recoverable energy is generated when the vehicle slides or brakes, the energy utilization rate is largely improved, and the cruising capacity of the vehicle is improved. Meanwhile, the vehicle is driven by a rear axle, a drive motor is connected with the rear axle by directly inserting the motor, an intermediary transmission mechanism is omitted, and the structure is more compact; intermediary losses can also be reduced, and the transmission efficiency is higher. The utilization rate of a battery can be effectively increased, so that the cruising capacity of the vehicle is higher.

Owner:苏州市京达环卫设备有限公司

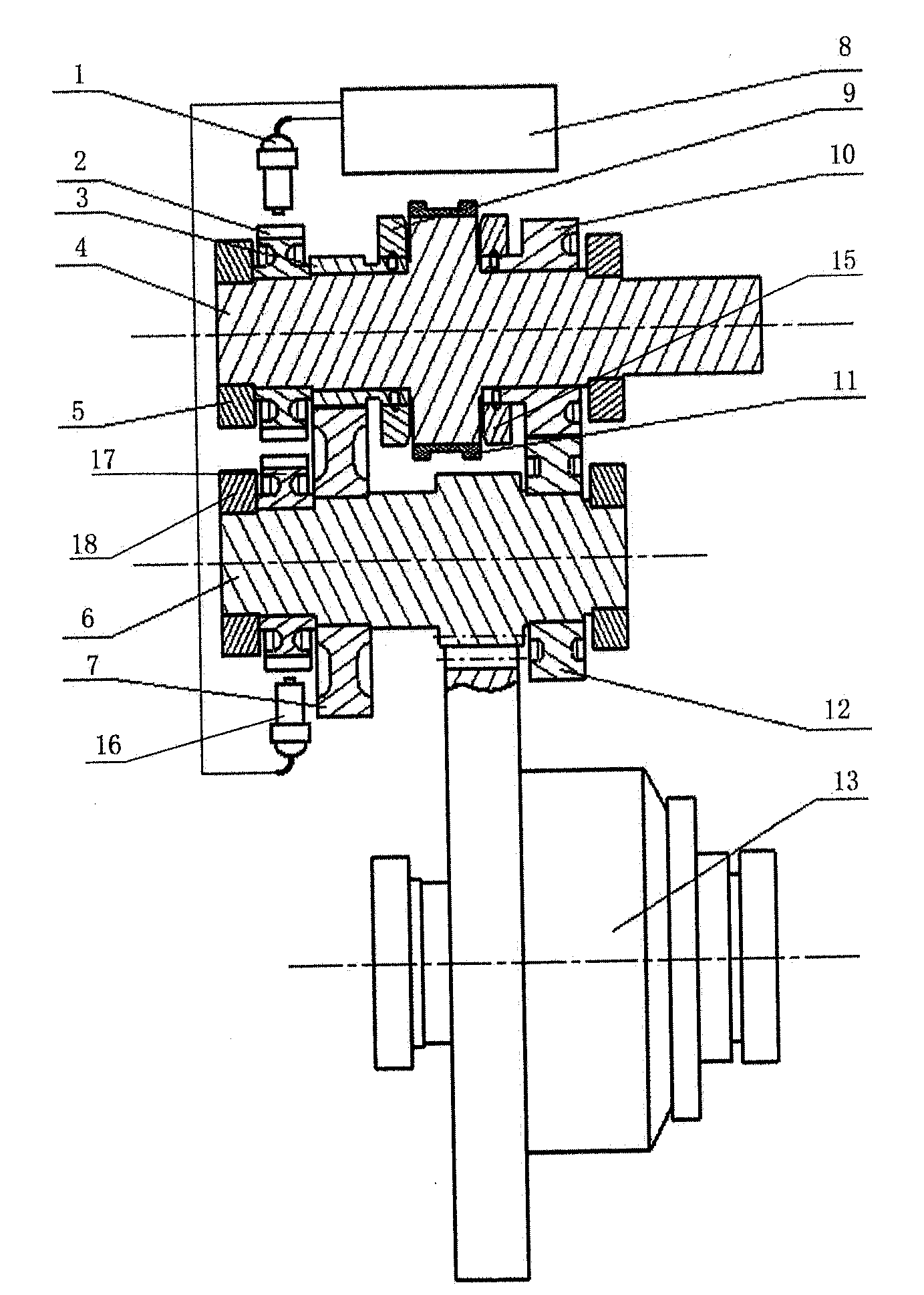

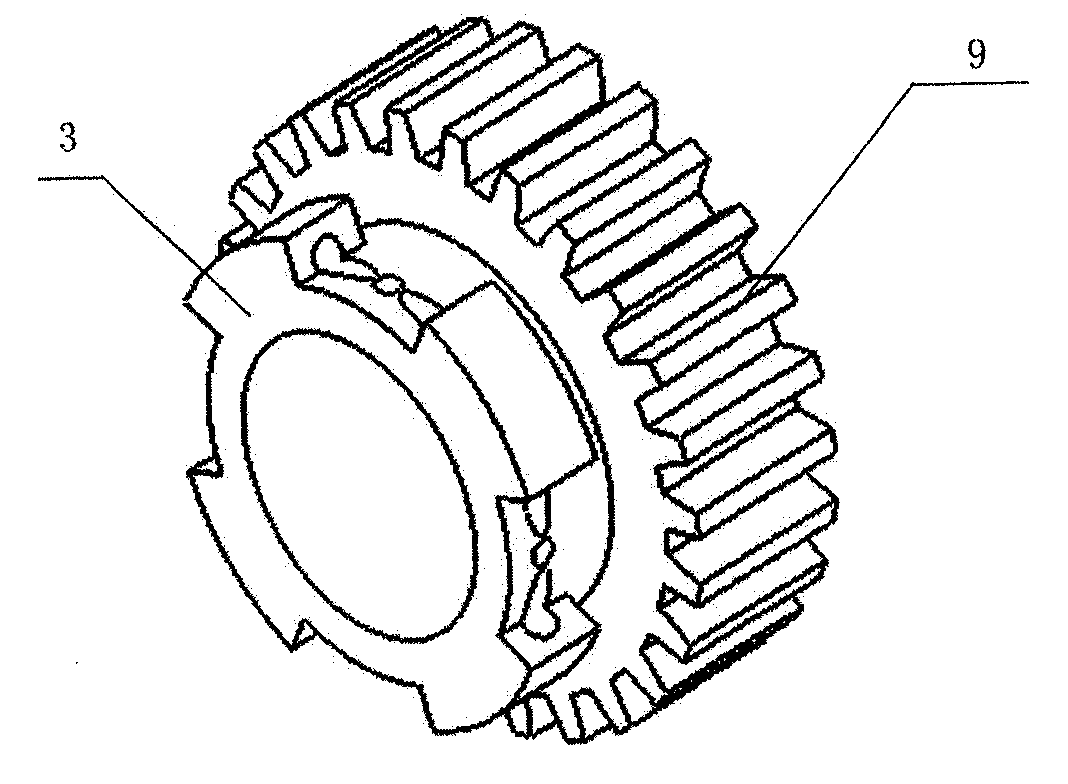

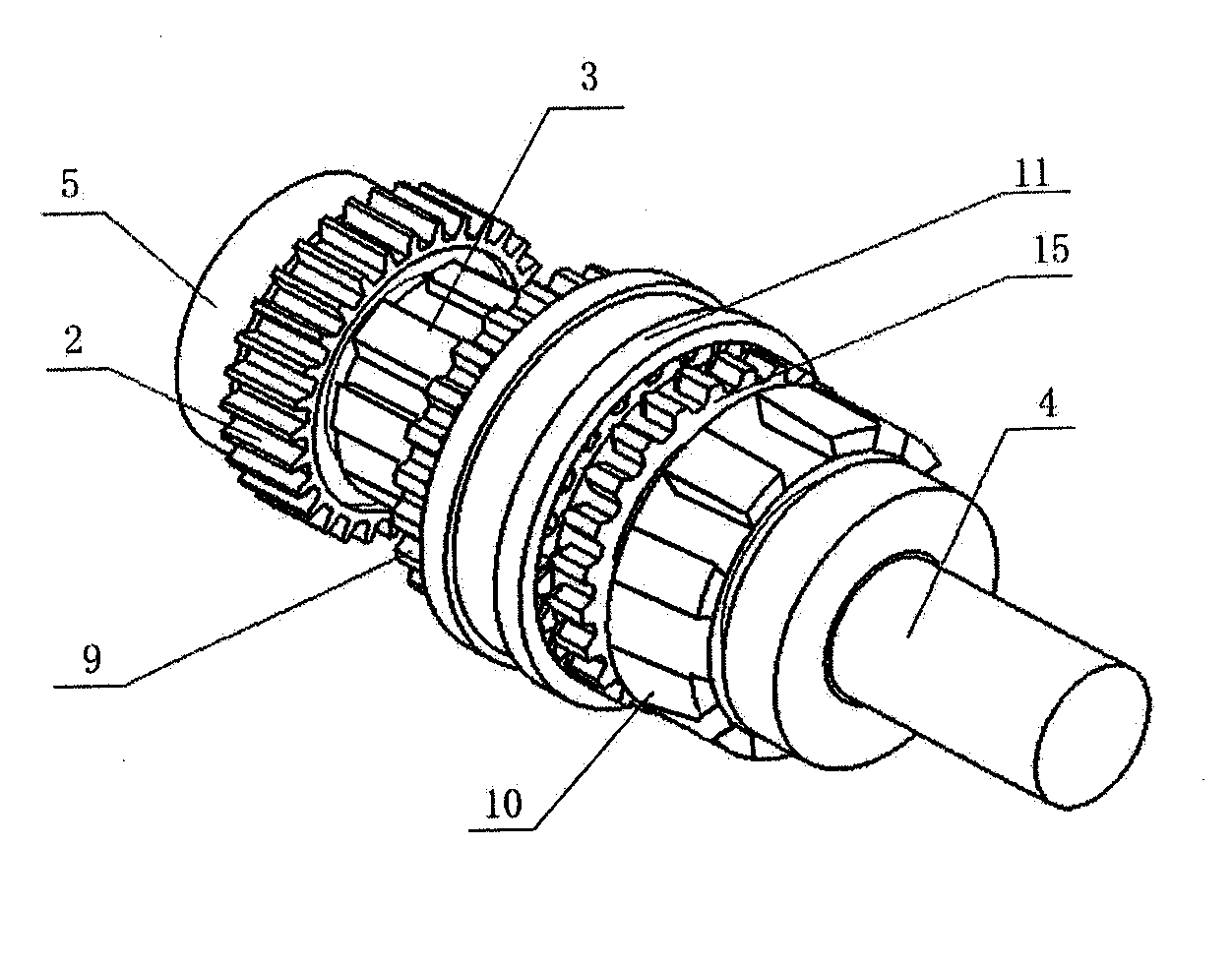

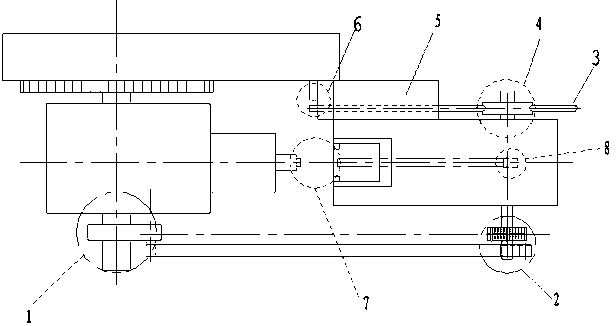

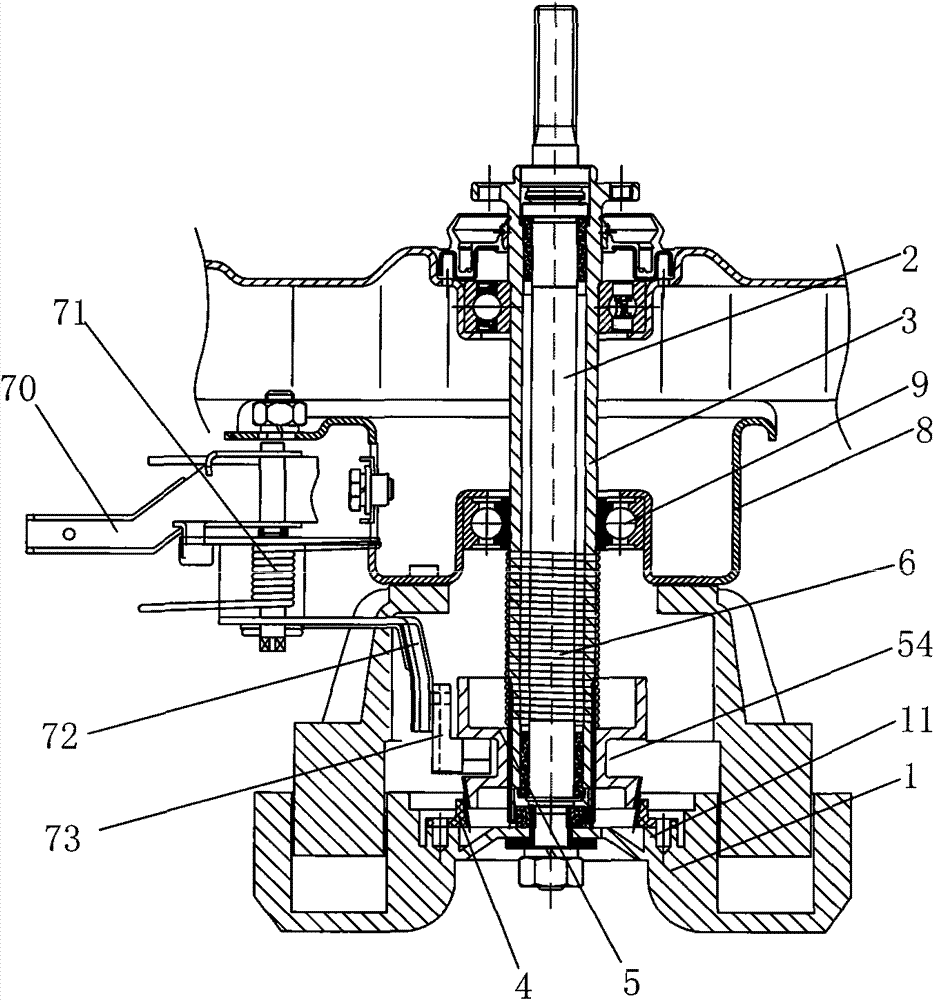

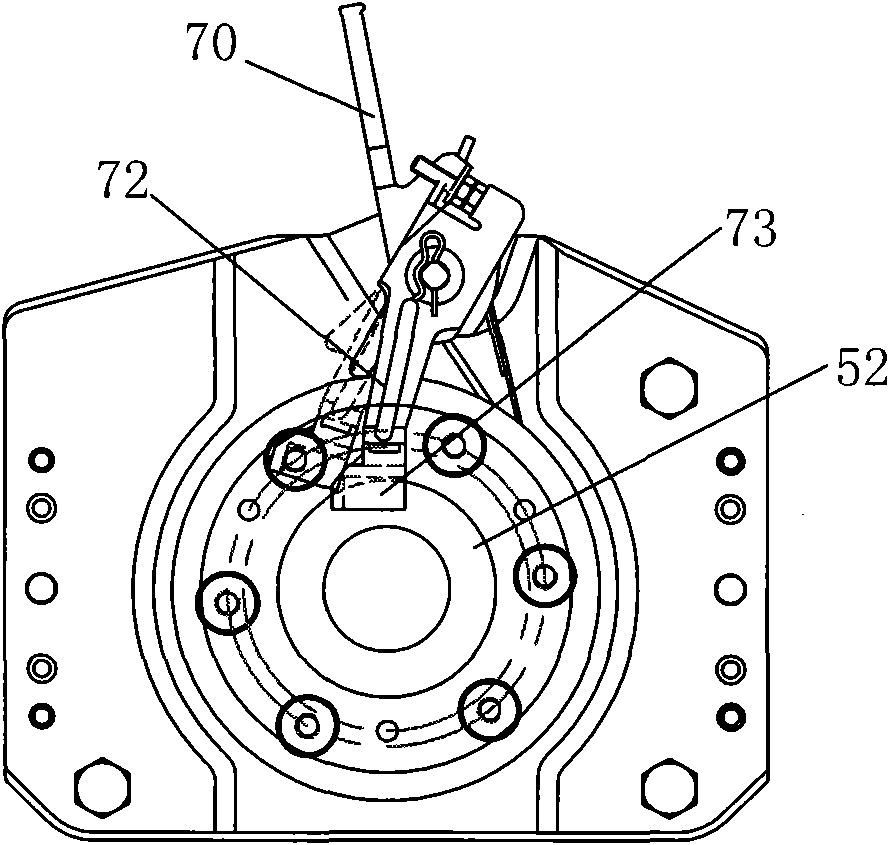

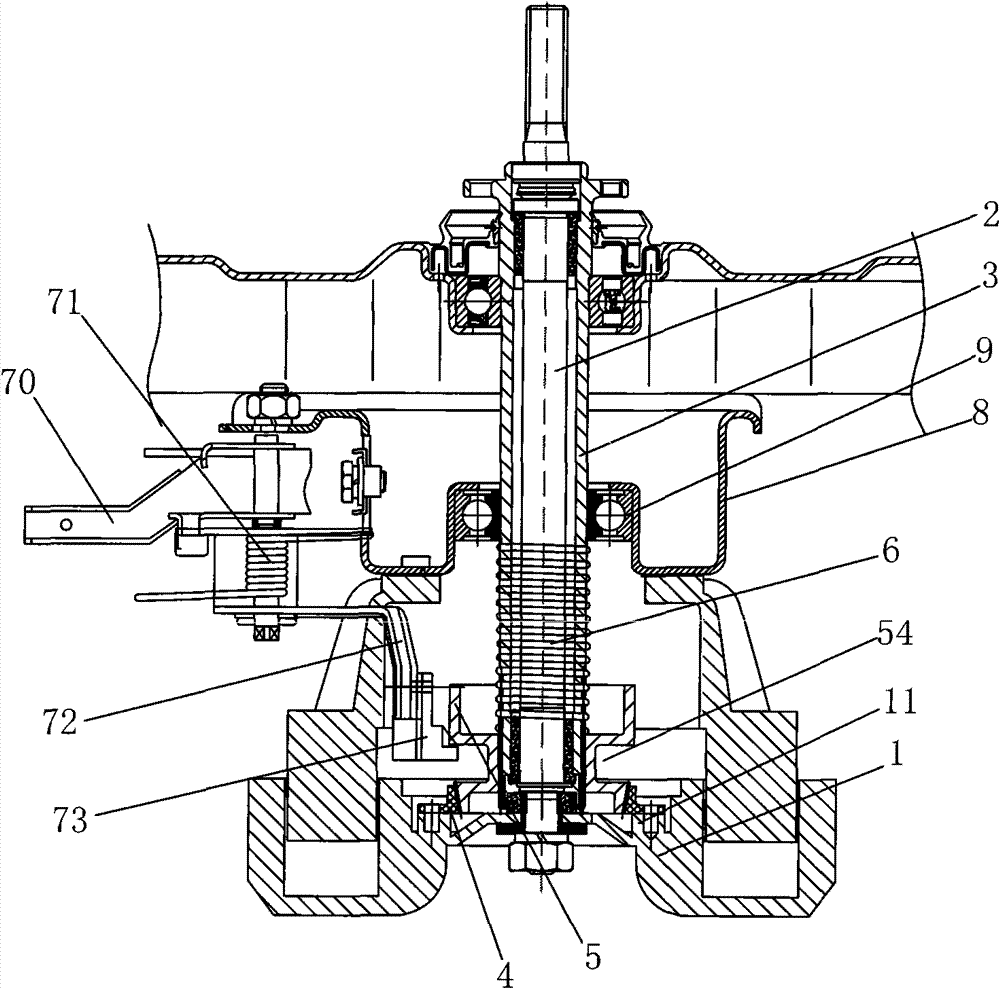

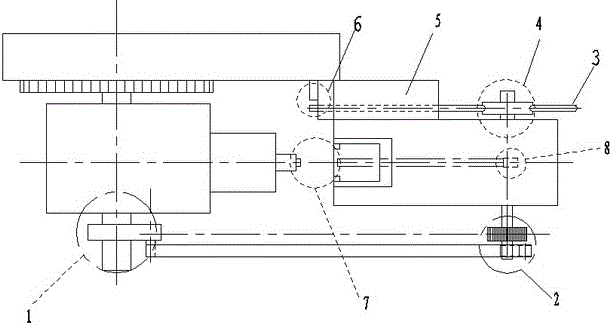

Two-stage automatic gear shift transmission device

InactiveCN101782132AExtended service lifeEasy accessToothed gearingsGearing controlDrive wheelDrive shaft

The invention discloses a two-stage automatic gear shift transmission device. A driving wheel I (3) of a first gear transmission device is engaged with a driven wheel I (7) of the first gear transmission device, and a driving wheel II (10) of a second gear transmission device is engaged with a driven wheel II (12) of the second gear transmission device. The driving wheel I (3) and the driving wheel II (10) are connected with a driving shaft (4) in a sliding way. The driving wheel I (3) and the driving wheel II (10) rotate in circumferential direction along the driving shaft (4). The driven wheel I (7) and the driven wheel II (12) are fixed on a driven shaft (6) and rotate synchronously with the driven shaft (6). The driven shaft (6) is connected with a differential (13) in a gearing way. A gear shift synchronizer is arranged between the driving wheel I (3) and the driving wheel II (10). A gear shift control device is connected to the gear shift synchronizer. The invention can optimally match with electric power output characteristics, reduce the intermediate loss and improve the driving comfort.

Owner:TAIZHOU KEMEIDA AUTO TECH DEV

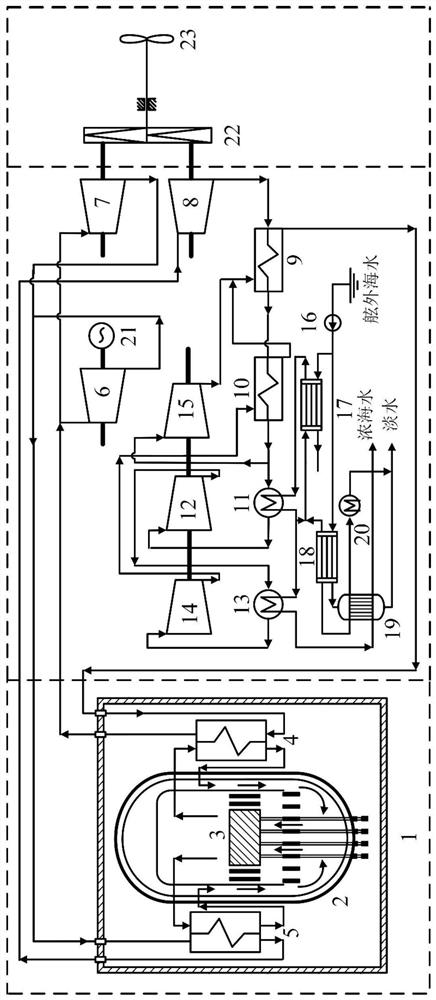

Supercritical carbon dioxide circulation and seawater desalination coupled vessel nuclear power system

InactiveCN112249293AImprove performanceGive full play to the advantages of high efficiencyPower plants using nuclear energyPropulsion based emission reductionIntercoolerSeawater

The invention discloses a supercritical carbon dioxide circulation and sea water desalination coupled vessel nuclear power system which comprises a reactor cabin, a ship cabin and a propelling device,the reactor cabin comprises a high-temperature gas cooled reactor system, and the ship cabin comprises a supercritical carbon dioxide power circulation system and a sea water desalination subsystem.A first-stage intermediate heat exchanger and a second-stage intermediate heat exchanger are arranged on the two sides of a high-temperature gas cooled reactor in the high-temperature gas cooled reactor system correspondingly. The supercritical carbon dioxide power circulation system is coupled with the high-temperature gas cooled reactor system through a first-stage intermediate heat exchanger and a second-stage intermediate heat exchanger. The seawater desalination subsystem is coupled with the supercritical carbon dioxide power circulation system through a precooler and an intercooler. Thepropelling device is connected with the supercritical carbon dioxide power circulation system. Vessel propulsion power and electric power are provided through the supercritical carbon dioxide circulation system, fresh water needed by the whole vessel is provided in cooperation with the sea water desalination system, the vessel is driven to sail in a direct propulsion mode, and the energy conversion rate and the device compactness are improved.

Owner:SOUTHEAST UNIV

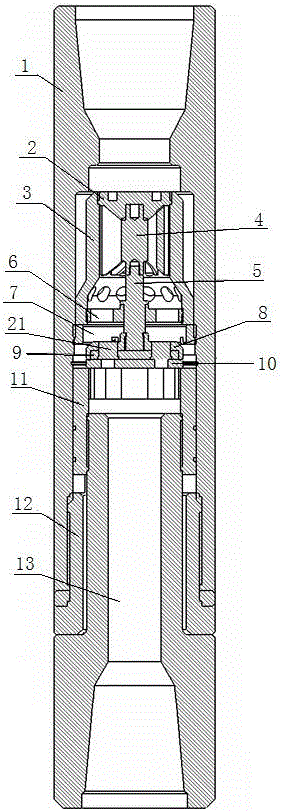

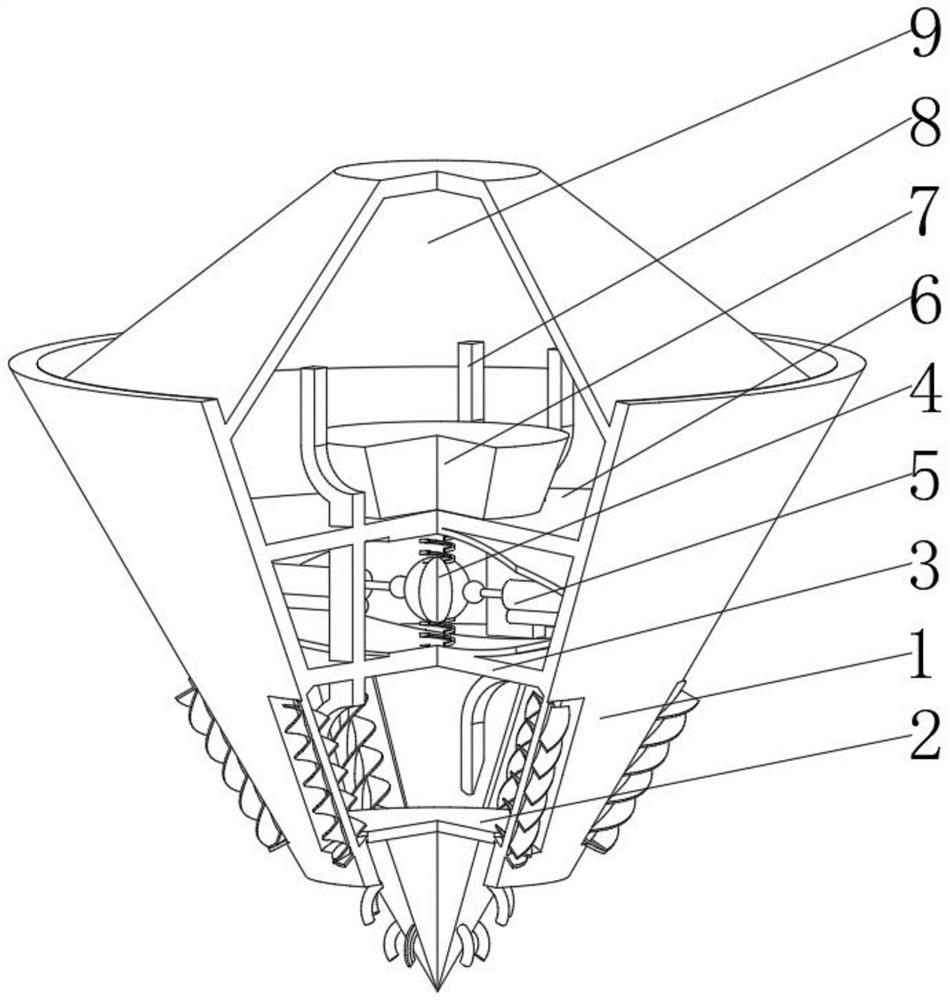

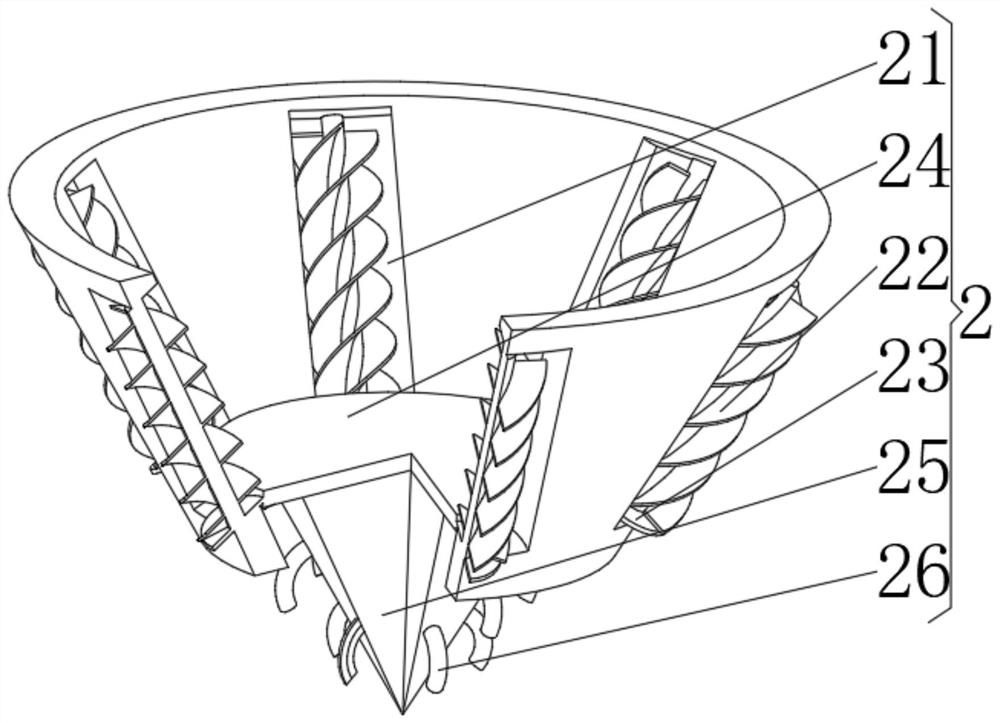

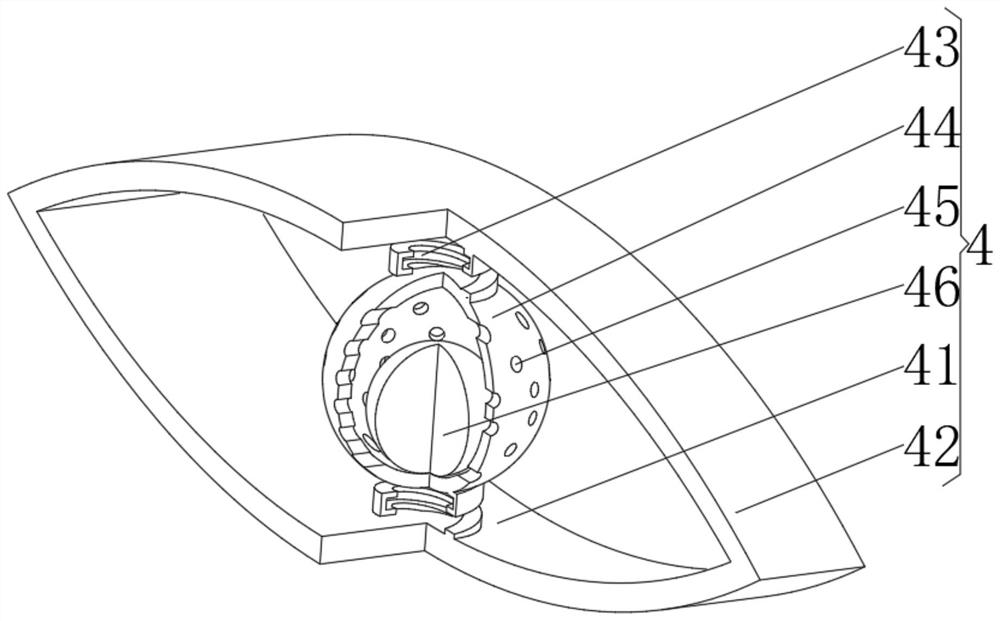

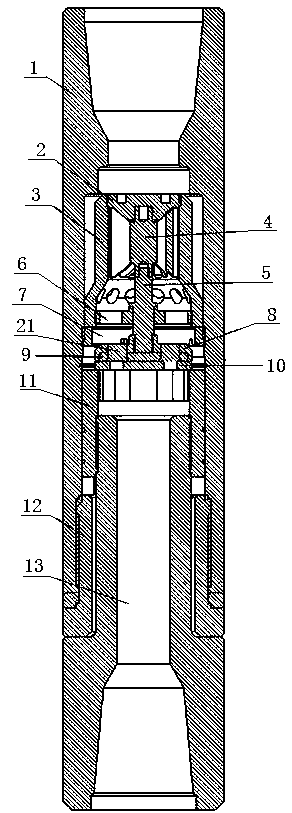

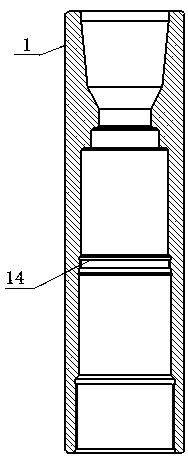

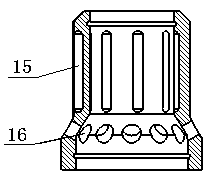

Pulsed-jet longitudinal impactor

InactiveCN106703686AImprove rock breaking efficiencyReduce intermediate lossBorehole drivesEngineeringEnergy consumption

The invention relates to a pulsed-jet longitudinal impactor. The lower end of a pump upper cover and the upper end of a pump outer cover are connected through a thread, the lower end of the pump upper cover is connected with a central rotor, the upper end of a pump middle shaft is provided with a thread, and the pump middle shaft is fixed at the lower end of the central rotor and sits on a lower cover plate through a boss; the lower cover plate is fixed inside the lower end of the pump outer cover and fixes the central rotor and the pump middle shaft inside the pump outer cover at the same time, the pump outer cover is fixed inside a main pup joint by a fixing cover nut, a valve is fixed at the lower end of the pump middle shaft, and an upper valve plate is fixed inside the valve through a fixing bolt; a lower valve plate is fixed at the upper end of an impact valve which is provided with a thread, the impact valve is in threaded connection with an impact joint which is fixed inside a hexagonal sleeve, the upper portion of the main pup joint is connected with an upper drill column while the lower portion of the same is connected with the hexagonal sleeve, and the impact valve is fixed above the hexagonal sleeve and provided with a passageway inside. The pulsed-jet longitudinal impactor is few in middle structure, low in energy consumption, large in impact force and long in service life.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

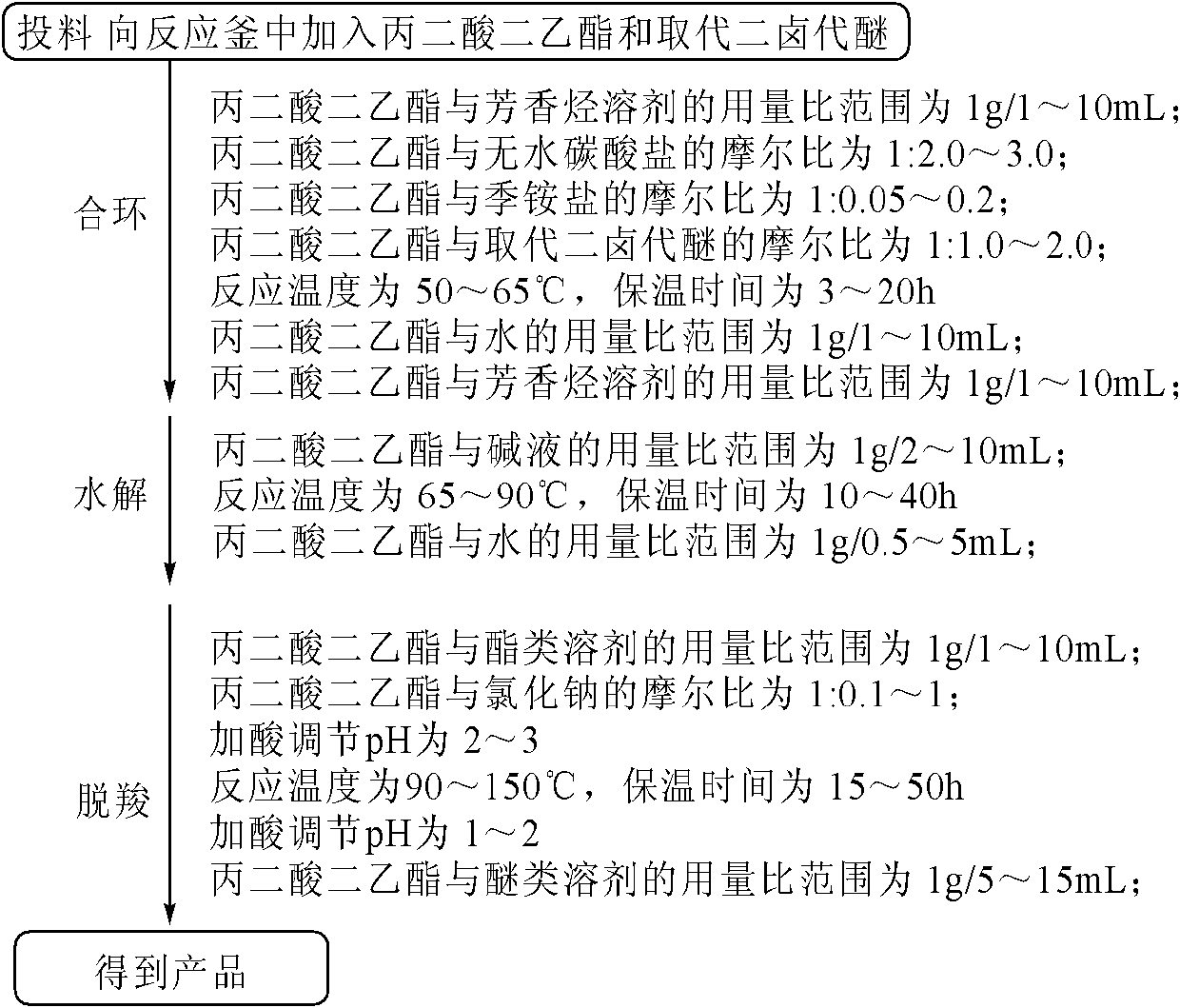

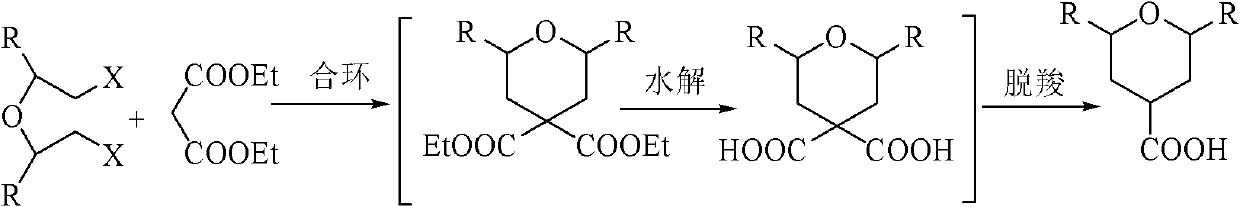

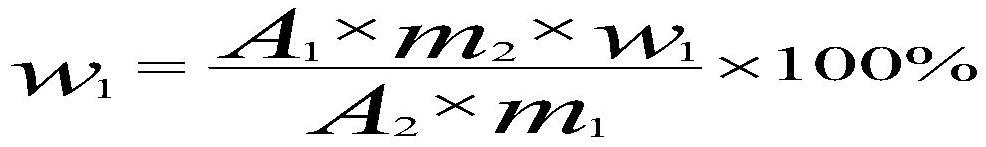

Preparation method of tetrahydropytanyl-4-formic acid and derivatives thereof by one-pot process

The invention relates to a preparation method of tetrahydropytanyl-4-formic acid and derivatives thereof by a one-pot process, which comprises the following steps: by using diethyl malonate which is industrialized in the market or easily prepared as an initial raw material, cyclizing with substituted dihalogenated ether (X is -Cl, -Br or -I), hydrolyzing, and decarboxylating to obtain the tetrahydropytanyl-4-formic acid and derivatives thereof. The method has the advantages of cheap and accessible raw materials, stable technological conditions and higher reaction purity and yield (the yield is 75.6-82.2%), is simple to operate in the whole production process, shortens the production time, enhances the yield, is suitable for large-scale production, and provides a new thinking and method for preparing the tetrahydropytanyl-4-formic acid and derivatives thereof.

Owner:ASYMCHEM LAB TIANJIN +4

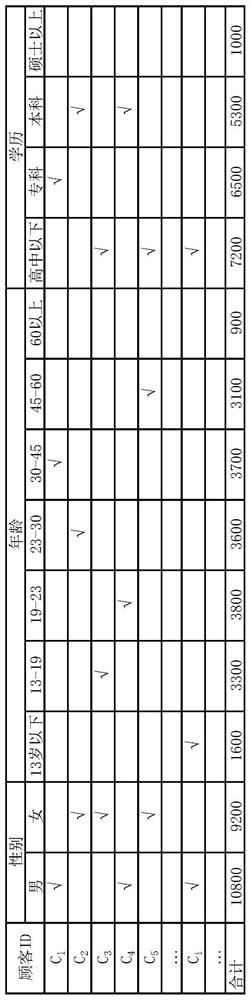

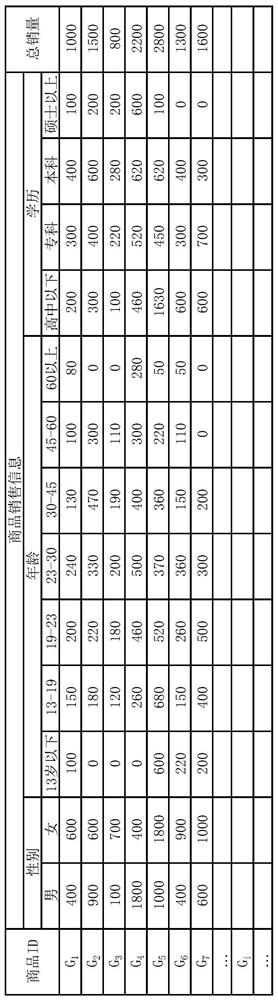

Electronic mall management system integrating agricultural service resources

PendingCN111652697AReduce lossReduce expenditure costBuying/selling/leasing transactionsResourcesData profilingUser management

The invention provides an electronic mall management system integrating agricultural service resources, which comprises an online server and an offline server, and is characterized in that the onlineserver comprises a user management unit, a commodity management unit, a data analysis unit, an artificial intelligence management unit and an order management unit, and the offline server comprises aheadquarters service platform and a basic service station. The system provided by the invention can improve the usability of the user and the probability of finding the commodity in a short time, andsaves the commodity selection and purchase time.

Owner:刘海涛

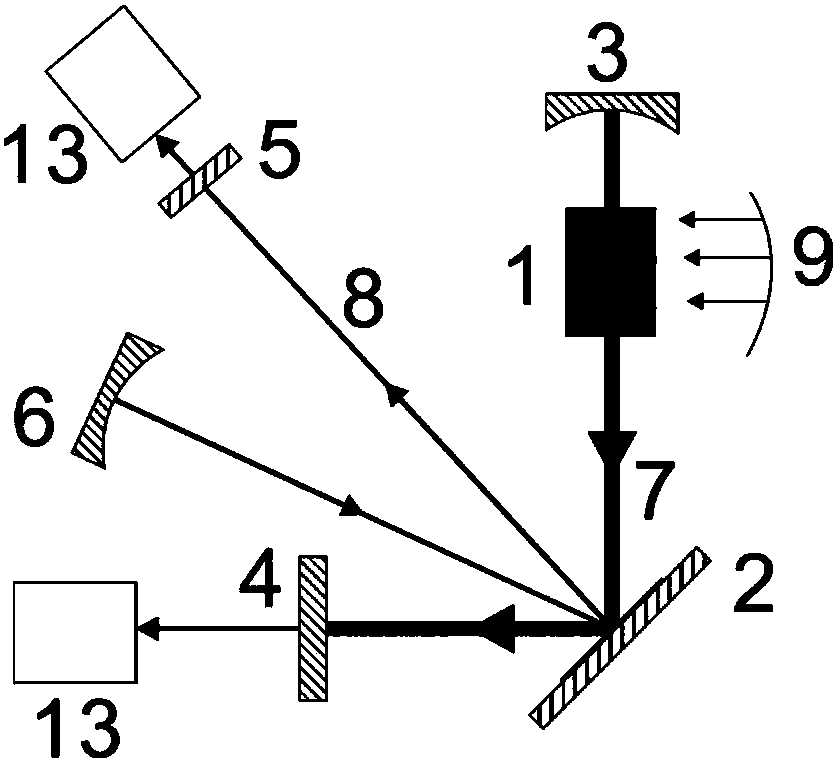

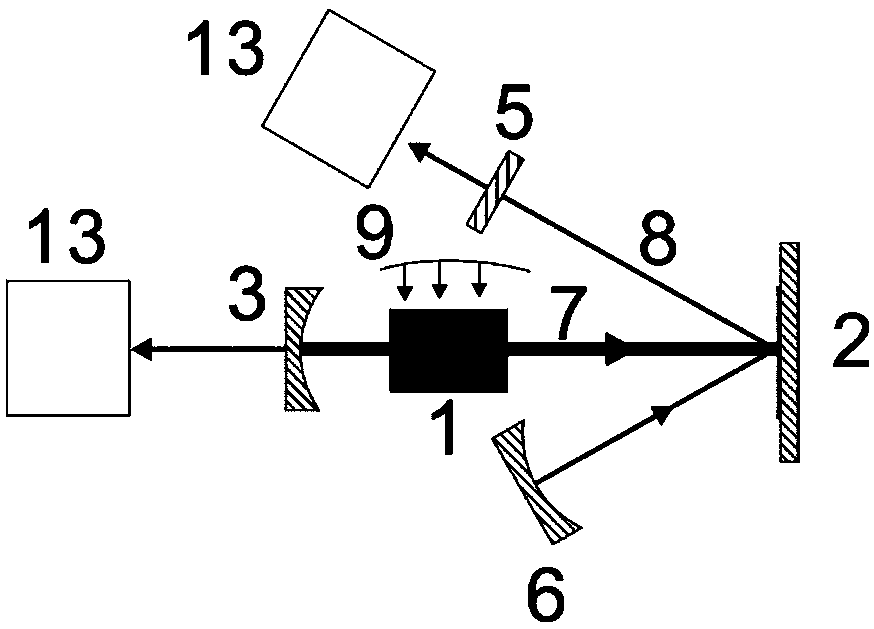

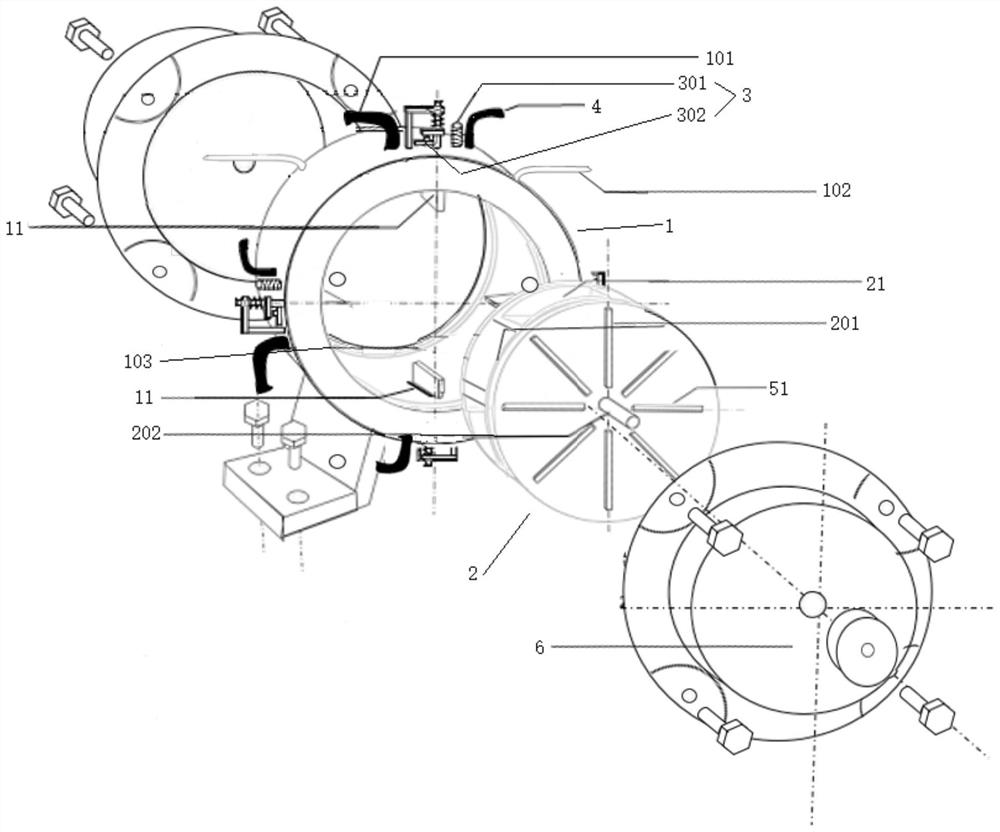

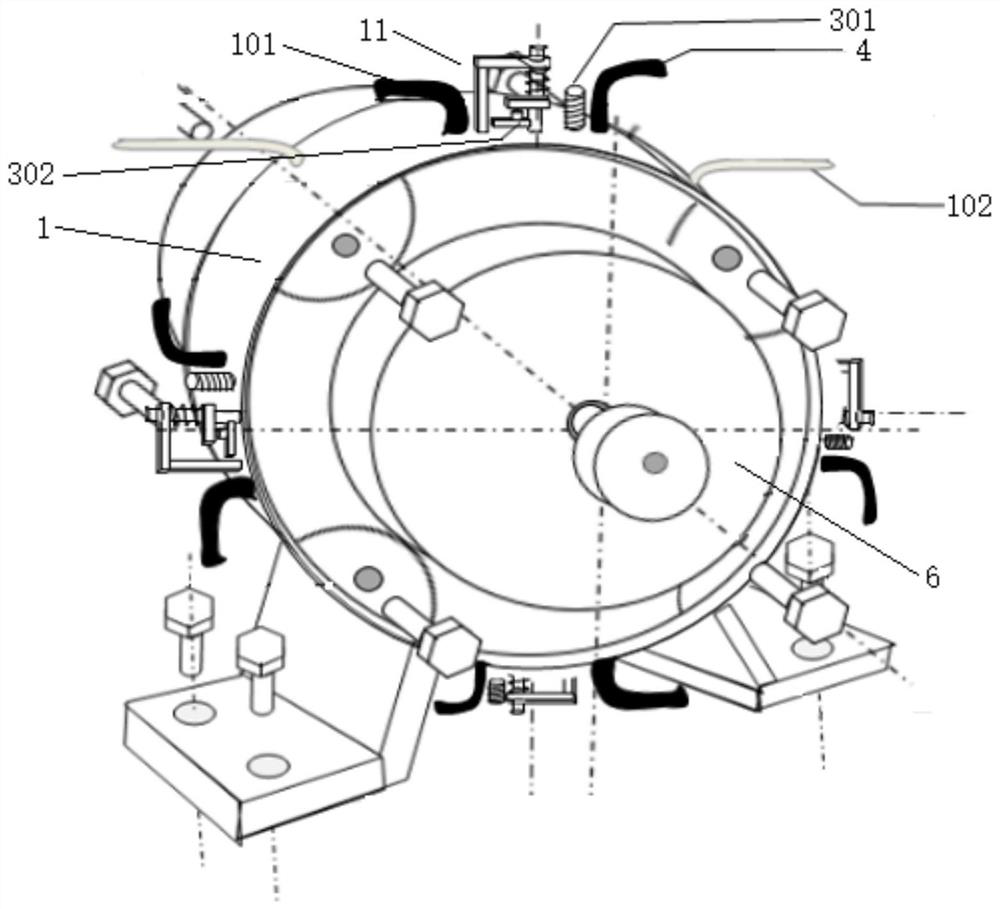

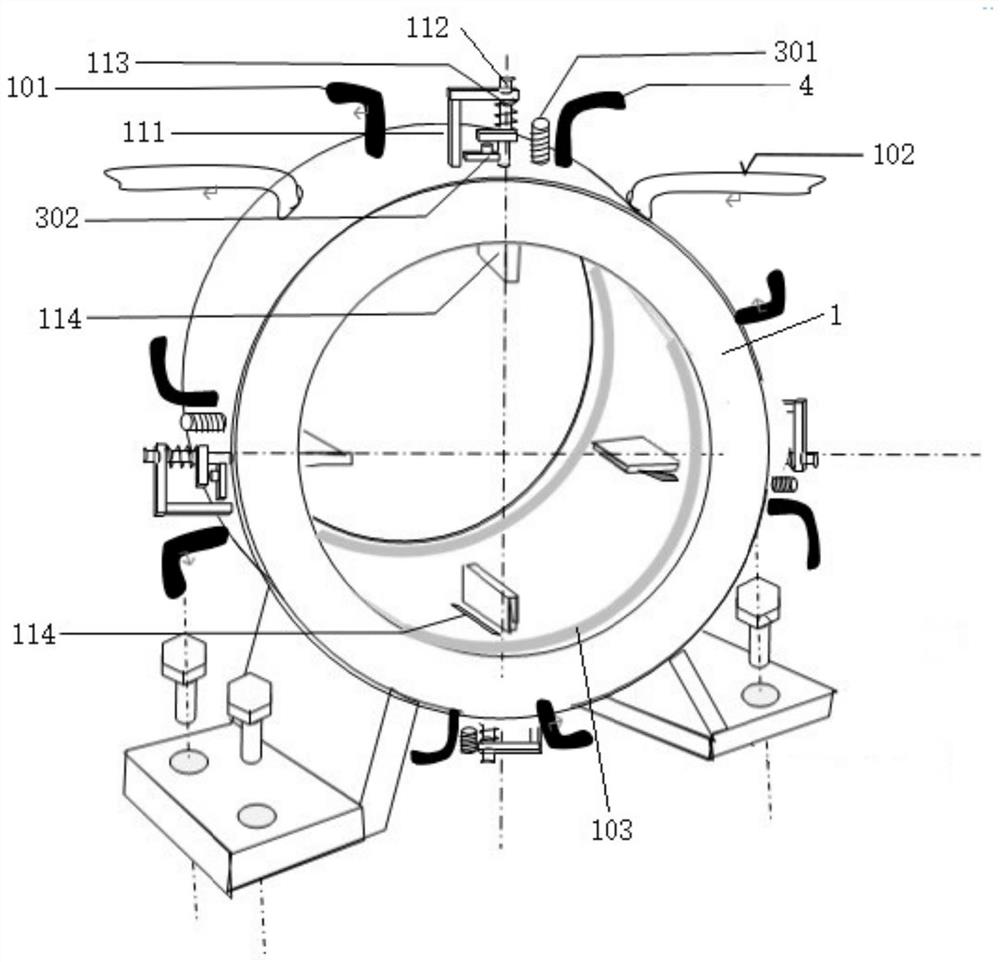

Resonant cavity inside-pumped disk laser

PendingCN107845948AIncrease laser powerAbsorb moreActive medium shape and constructionResonant cavityDisk laser

The invention discloses a resonant cavity inside-pumped disk laser, which comprises an active gain mirror, a pump laser with the active gain mirror inserted in a resonant cavity, and a disk laser resonant cavity. According to the invention, a resonant cavity is based on a conventional pump cavity and is further inserted with a gain material made into a sheet to form a reflective mirror of the resonant cavity, or is a resonant cavity formed by amplifying the stimulated radiation light of the sheet crystal itself. According to the invention, the high-power roundtrip laser in a laser resonant cavity is used to achieve the multi-pumping purpose for the disk laser, the disk laser crystal pumped power density in the resonant cavity is more than ten times higher than that outside the cavity, andthe absorption efficiency of the pump light by the disk crystal can be improved, especially for non-absorption peak pumping conditions. In the invention, the pump resonant cavity and the disk laser resonant cavity are independent of each other, the cascade pumping of the disk laser can be realized, and the Q modulation of the pump cavity can also realized to obtain the multi-wavelength, the narrowpulse width and the high peak power pulsed laser output.

Owner:HUAZHONG UNIV OF SCI & TECH

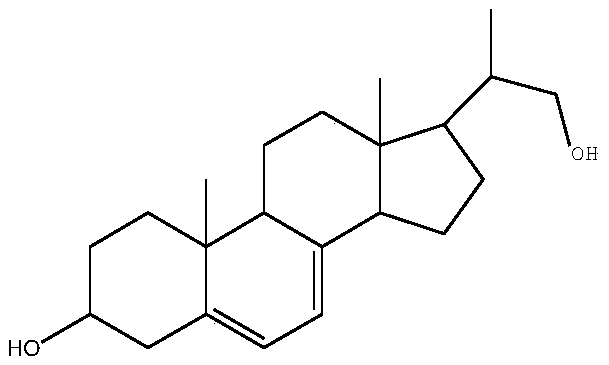

Method for preparing pregna-5-ene-3beta,21-diol by cell growth

InactiveCN111808906AReduce polarityImprove solubilityBacteriaMutant preparationBiotechnologyCell growth

The invention relates to a production method of steroid drug intermediates, in particular to a method for preparing pregna-5-ene-3beta,21-diol by cell growth. The method comprises the following steps:(1) 3-site protection on phytosterol; (2) transforming of growth cells; (3) extracting; (4) hydrolyzing; and (5) refining. The preparation method disclosed by the invention is relatively low in costand shorter in route, and omits a plurality of reaction steps and post-treatment steps. The shortening of the reaction route is also beneficial to the improvement of the reaction yield, and the intermediate loss is reduced. According to the method, the step of 3-site hydroxyl protection is adopted firstly, and growth cell biological fermentation reaction is carried out later, so that the solubility of the fermentation substrate in the fermentation liquor is directly increased, the fermentation is facilitated, the yield of the product can be increased, and the generation of impurities is reduced. The preparation method provided by the invention can also reduce the use of chemical reagents and is beneficial to environmental protection.

Owner:HUNAN NORCHEM PHARMACEUTICAL CO LTD

Synthetic technology for ofloxacin

The invention discloses a synthetic technology for ofloxacin. The synthetic technology comprises the following steps: weighting (S)-(-)-9,10-difluoro-2,3-dihydro-3-methyl-7-oxo-7 hydrogen pyridine (1,2,3-de) (1,4) benzo oxazine-6 carboxylic acid, N-methyl piperazine and dimethyl sulfoxide at a ratio; adding into a reactor in turn; heating, stirring and reacting for 4-8h under the environment at 110-150 DEG C, thereby forming a mixed solution; filtering, adding an alkyl imidazole L-tartrate ionic solution, and heating, stirring and reacting for 30-45min under the environment at 60-80 DEG C; adding an organic solvent, mixing and stirring; reducing pressure and recycling dimethyl sulfoxide and excessive N-methyl piperazine; utilizing 90-95% ethyl alcohol to crystallize the residual solution; and performing hydrolysis reaction, thereby obtaining the ofloxacin. The invention can effectively reduce the happening of side reaction and can increase the yield of condensation reaction.

Owner:武汉励合生物医药科技有限公司

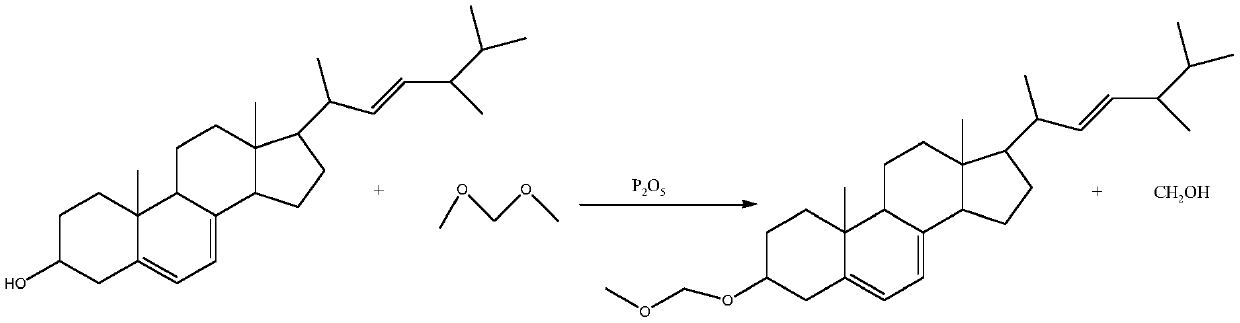

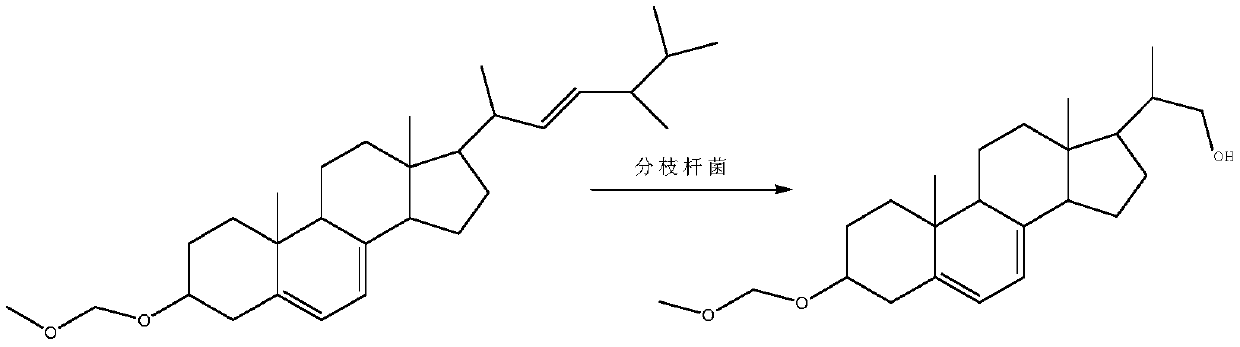

Method for preparing intermediate by using resting cell biological fermentation of ergosterol etherate

InactiveCN110951815AReduce polarityImprove solubilityBacteriaMicroorganism based processesBiotechnologyHydrolysis

The invention belongs to production methods of steroidal drug intermediates, and in particular relates to a method for preparing an intermediate by using resting cell biological fermentation of an ergosterol etherate. The method comprises the following steps: (1) 3-position protection; (2) resting cell transformation; (3) extraction; (4) hydrolysis; and (5) refining. The preparation method of theinvention has relatively low cost and relatively short route, and saves many reaction steps and post-treatment steps, and the shortening of the reaction route is also beneficial to improvement of thereaction yield and reduction of intermediate loss. According to the method, the step of 3-hydroxyl protection is performed first, and then a biological fermentation reaction of growing cells is performed, so that the solubility of a fermentation substrate in a fermentation liquid is directly increased, fermentation is conducive to performing, the yield of a product can be improved, and the production of impurities is reduced. The preparation method of the invention can also reduce the use of chemical reagents, and is beneficial to environmental protection.

Owner:HUNAN NORCHEM PHARMACEUTICAL CO LTD

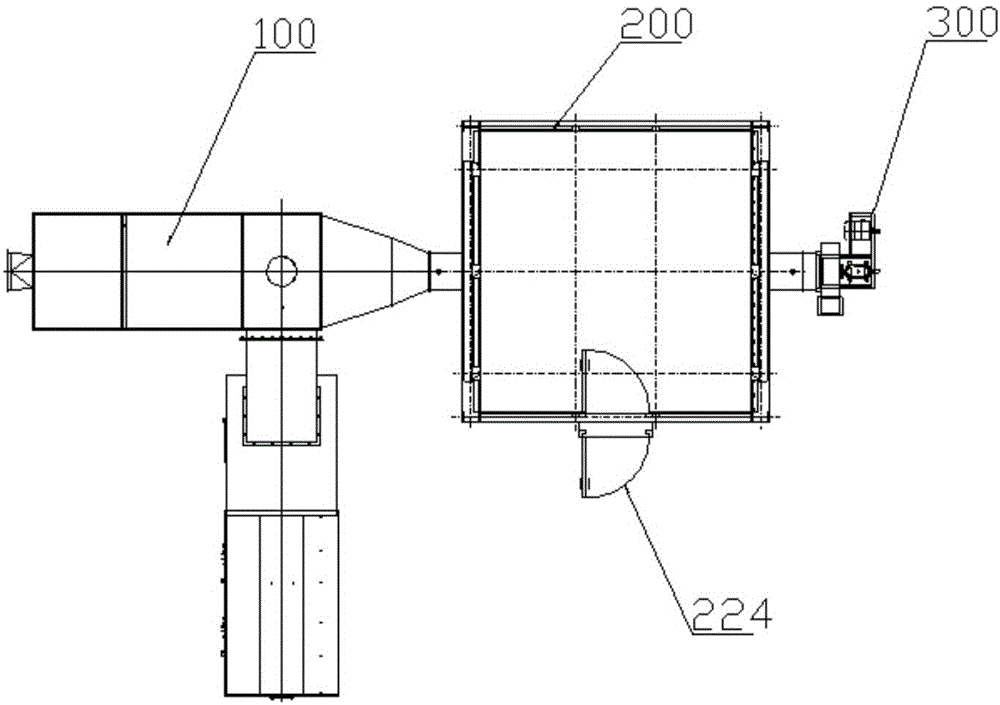

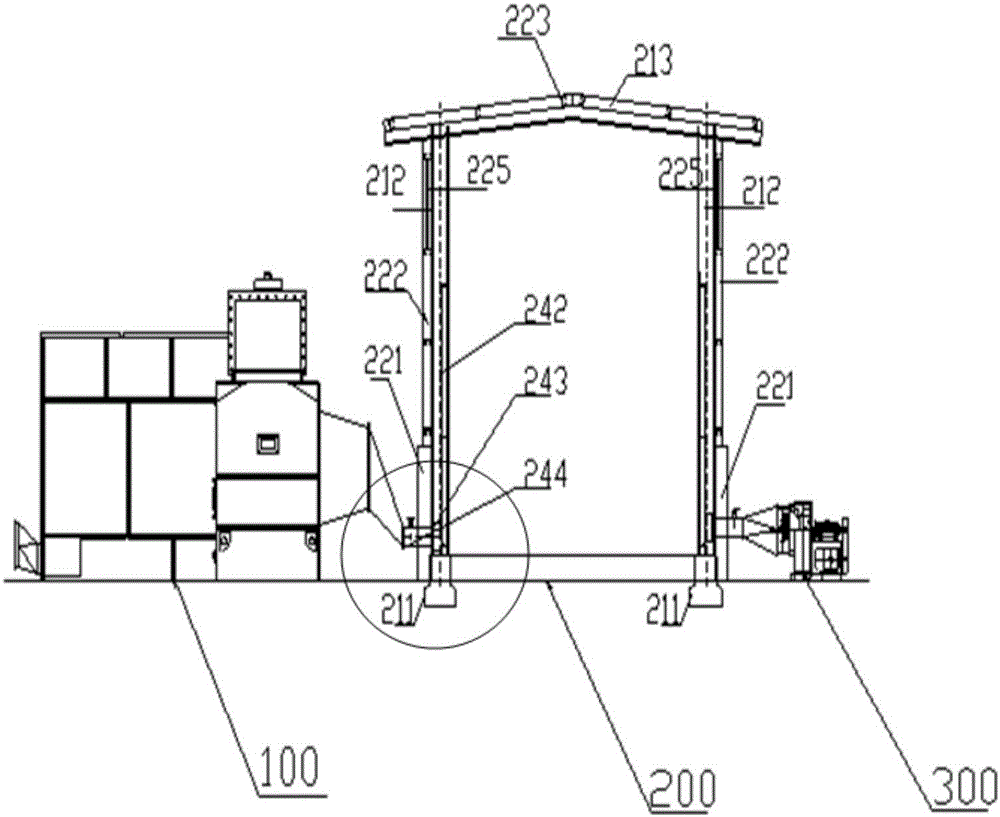

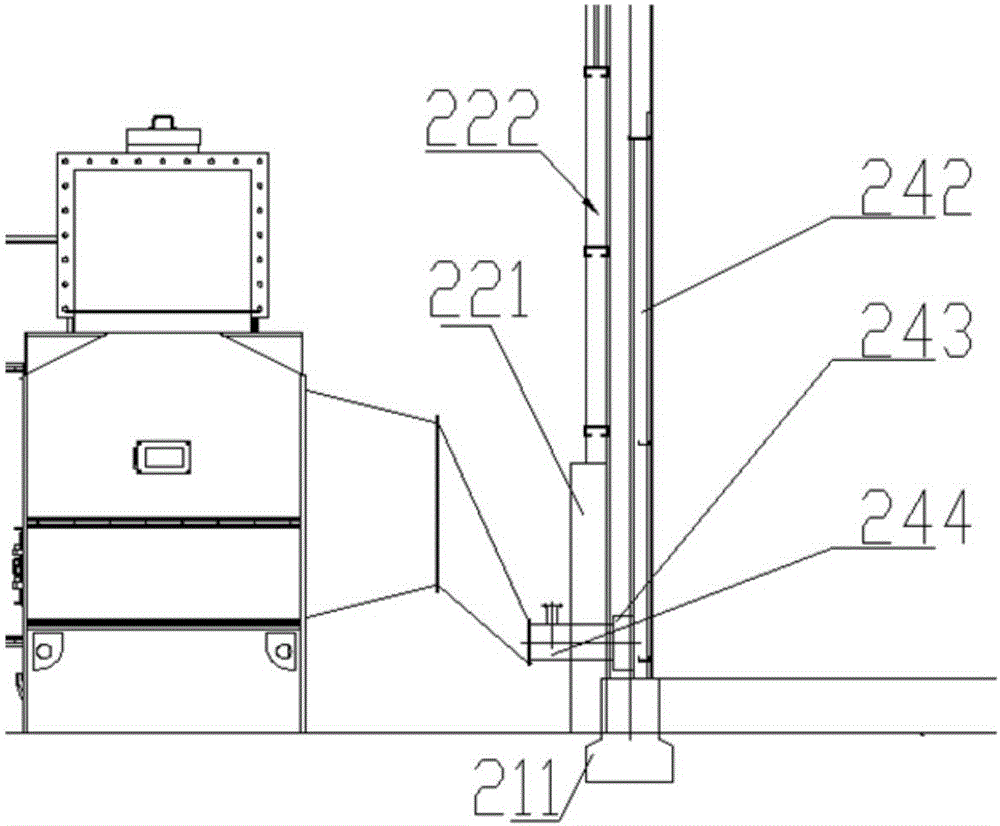

Grain drying bin with hidden air ducts and control method of grain drying bin

ActiveCN106063412ASimple structureSimple and fast operationAgriculture tools and machinesSeed preservation by dryingAgricultural engineeringHot blast

The invention discloses a grain drying bin with hidden air ducts. The grain drying bin comprises a bin body, a hot-blast stove, and an induced draft fan, wherein the bin body comprises two inlet and outlet air ducts, and is used for accommodating to-be-dried grain; the hot-blast stove is connected to one side of the bin body through one inlet and outlet air duct, and is used for introducing a hot blast into the drying bin; the induced draft fan is connected to the other side of the bin body through the other inlet and outlet air duct, and is used for pumping out the hot blast in the bin body; the bin body is of an interlayer structure, a horizontal main air duct and vertical hidden air ducts, the horizontal main air duct is connected with the two inlet and outlet air ducts, and the plurality of vertical hidden air ducts are evenly distributed in an interlayer of two side surfaces of the bin body; the upper ends of the vertical hidden air ducts are sealed, and the lower ends of the vertical hidden air ducts are communicated with the horizontal main air duct; vent holes are evenly distributed in the side, close to the grain, of each vertical hidden air duct, and are used for introducing a hot blast into the grain. The grain drying bin with the hidden air ducts realizes the combination of drying and storage, reduces the cost for transportation, and has the advantage of reducing middle loss.

Owner:JILIN UNIV +1

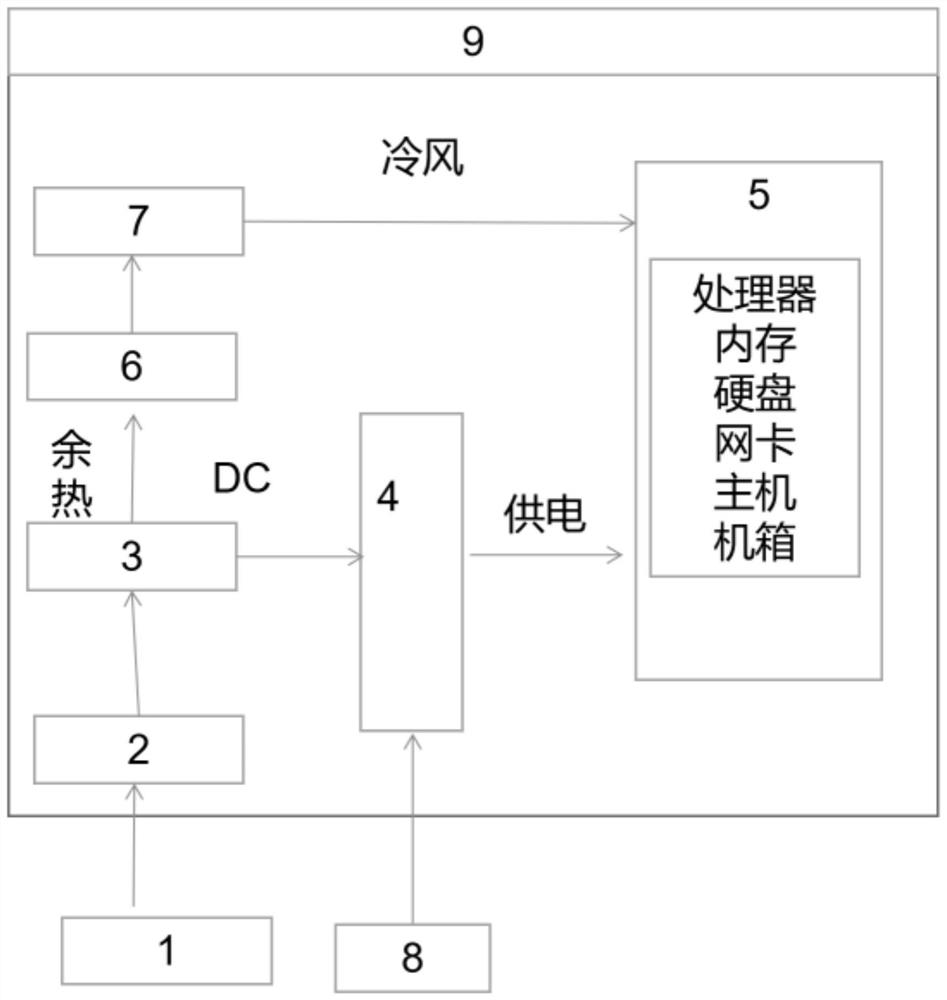

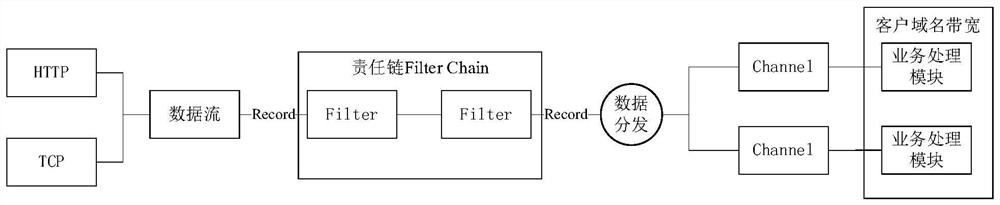

Fuel cell power supply and refrigeration integrated cabinet and data center

PendingCN114071963AReduce intermediate lossImprove efficiencyFuel cellsCooling/ventilation/heating modificationsFuel cellsPower usage

The invention discloses a fuel cell power supply and refrigeration integrated cabinet and data center, and aims to solve problems of complex structure and serious energy loss of the data center due to the fact that energy supply and energy use are separately arranged in the existing data center. A fuel cell is directly combined with a terminal energy consumption equipment cabinet, so direct power supply is realized, distributed refrigeration of the cabinet can be realized, refrigeration efficiency is greatly improved, electric cooling energy supply efficiency is remarkably improved, and the PUE is obviously reduced. Through the integrated design, the power supply module, the refrigeration module and the power utilization module are combined together, direct-current power supply and direct cooling for the cabinet server are achieved, popularization of green electricity in a data center is achieved, intermediate loss of power supply and refrigeration is greatly reduced, and efficiency is improved.

Owner:宝武清洁能源有限公司

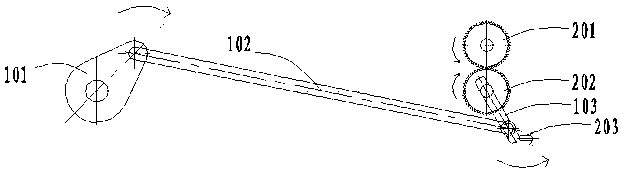

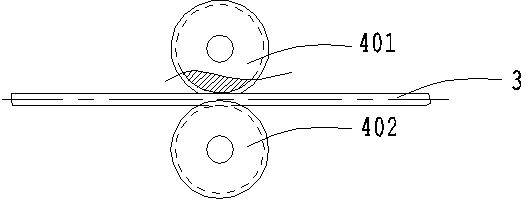

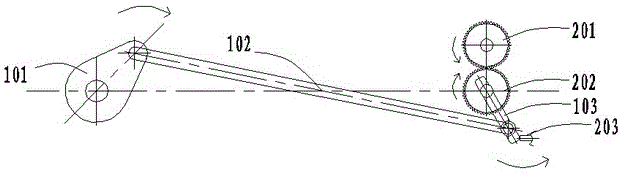

Hot forging composite machining device and method

ActiveCN103264283AImprove performanceImprove machining accuracyOther manufacturing equipments/toolsEngineeringMachining

The invention provides a hot forging composite machining device and method. The device comprises a drive mechanism, a transmission mechanism, a heating mechanism, a blanking mechanism, a hot forging forming mechanism, a discharging mechanism and an induction mechanism. The transmission mechanism is connected with the drive mechanism, the heating mechanism is arranged between the feeding mechanism and the transmission mechanism, the hot forging forming mechanism is arranged below the blanking mechanism and connected with the discharging mechanism, and transmission variables of the transmission mechanism are transmitted to the blanking mechanism through the induction mechanism. The hot forging composite machining method comprises the steps that a) the drive mechanism drives the transmission mechanism to transfer hot forging materials to the heating mechanism, and the transmission variables are transmitted to the blanking mechanism through the induction mechanism; b) the hot forging materials are heated; c) the heated hot forging materials are transferred to the blanking mechanism for blanking; d) forging forming is performed, and e) discharging is performed. According to the hot forging composite machining device and method, unmanned operation and smooth transition of work sections during hot forging are guaranteed, the stable performance of the work sections is guaranteed, automation is achieved, the machining efficiency is high, and molded parts are stable in quality.

Owner:RIFENG ENTERPRISE GRP CO LTD +1

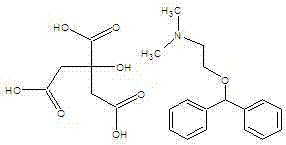

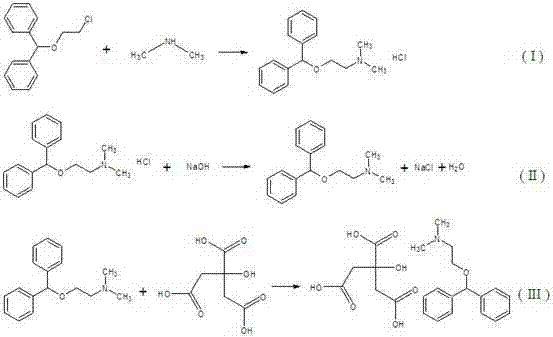

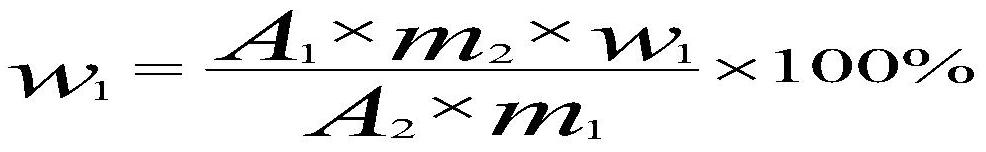

Method for synthesizing citric acid diphenhydramine

InactiveCN102229537ASimplify operation stepsReduce intermediate lossOrganic compound preparationCarboxylic acid salt preparationBenzeneOrganic solvent

The invention relates to a method for synthesizing citric acid diphenhydramine by a 'one boiler method'. The method comprises the following steps of: reacting diphenyl methanol-beta-chloroethylether with dimethylamine to generate diphenhydramine hydrochloride; adding sodium hydroxide to treat, so that the diphenhydramine is freed; and directly adding citric acid into the same reactor to perform acid-base reaction to prepare the citric acid diphenhydramine. By the method, an intermediate is not required to be separated and purified, so the operating steps can be simplified, yield of the products can be increased, production cycle can be shortened, and production cost can be reduced; the starting raw material diphenyl methanol-beta-chloroethylether can be obtained from a commercial channel or can be prepared by reacting diphenyl methanol with 2-chlorohydrin in the presence of concentrated sulfuric acid without using a toxic organic solvent, so the subsequent purification step is simplified and safety of personnel operation and products is improved; and a method for synthesizing the diphenyl methanol-beta-chloroethylether is combined with the method for synthesizing the citric acid diphenhydramine, remarkable effects of simplifying the operating steps, increasing the yield of the products and reducing the production cost are achieved.

Owner:SOUTHWEST UNIVERSITY

Method for preparing dehydroepiandrosterone by microbial fermentation

ActiveCN102816825BConvenient researchLow costMicroorganism based processesFermentationMicroorganismPlant sterol

The invention relates to a production method of midbodies of sterides drugs, in particular to a method for preparing dehydroepiandrosterone by microbial fermentation. The method includes the following steps of firstly, protecting three hydroxy of sterol to obtain protections; secondly, fermenting the protections by bacterial strain Mycobacteriumsp.NRRLB-3683 or 3805; thirdly, hydrolyzing a target object; and fourthly, purifying. The invention further provides a new path for preparing dehydroepiandrosterone from plant sterol, production cost of dehydroepiandrosterone is greatly reduced and quality yield of the dehydroepiandrosterone is improved.

Owner:HUNAN NORCHEM PHARMACEUTICAL CO LTD

Method for extracting hesperidin from citrus to prepare hesperetin

InactiveCN113686990AReduce intermediate lossShorten the production cycleComponent separationCitrus volkamerianaProcess engineering

The invention relates to the technical field of extraction of plant effective components, in particular to a method for extracting hesperidin from citrus to prepare hesperetin, which comprises the following specific steps: S1, drying citrus, crushing, filtering with a screen, weighing 100 kg of powder, adding a solvent for extraction, adjusting the pH value to be alkaline, putting the powder into a self-made ultrasonic countercurrent extraction device for extraction for 120 minutes, filtering, collecting an extracting solution, extracting twice, combining the extracting solution, concentrating the combined extracting solution until the volume is 1 / (2-4) of the volume of the original extracting solution, filtering, adjusting the pH value to 3-4, standing and precipitating for 8 hours, filtering and collecting a precipitate, washing the precipitate with pure water until the precipitate is neutral, drying into powder, and weighing to obtain the citrus crude extract. According to the invention, the hesperetin is produced by designing and utilizing the waste citrus. Compared with the traditional process for preparing hesperetin by taking hesperidin as a raw material, the method has the advantages that the intermediate loss is reduced, the purification and drying links of the hesperidin are reduced, and the production period is greatly shortened.

Owner:广州健顺生物医药研究院有限公司

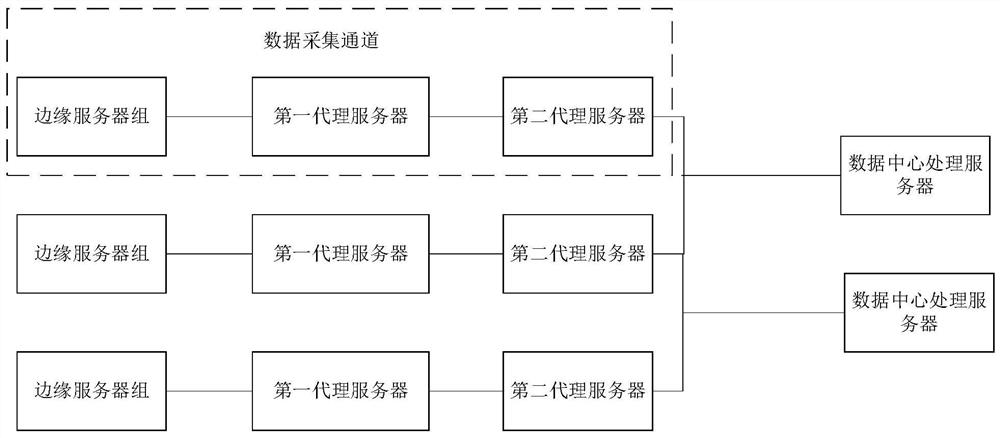

Data acquisition system

The embodiment of the invention relates to a data acquisition system, and the system comprises each edge server in an edge server group, which is used for receiving a user request; the first proxy server is used for performing first classification processing on the user request to obtain first summarized data; sending the first summarized data to a second proxy server; the second proxy server is used for carrying out second classification processing on the first summarized data to obtain second summarized data and respectively sending the second summarized data to each data processing center server; and each data processing center server is used for performing third classification processing on the second summarized data to obtain third summarized data when determining that the second summarized data is to-be-processed data in the jurisdiction range of the data processing center server. And the problems of overlarge load and low timeliness caused by the fact that the data processing center server classifies and processes all massive complex data at the same time are avoided.

Owner:CHINA TELECOM CLOUD TECH CO LTD

Fishing ground protecting equipment

InactiveCN112438248AProtection securityIncrease motivationPiezoelectric/electrostriction/magnetostriction machinesAnimal repellantsMarine engineeringStructural engineering

The invention discloses fishing ground protecting equipment which comprises a frustum outer frame, wherein a balancing mechanism is arranged at the bottom of the outer surface of the frustum outer frame, a sealing partition plate is fixedly connected to the position above the balancing mechanism on the inner surface of an inner cavity of the frustum outer frame, a floating strengthening mechanismis fixedly connected to a middle position of the top of the sealing partition plate, a vibration power generation mechanism is fixedly connected to a middle position between two sides of the inner cavity of the floating strengthening mechanism, a reflective partition plate is fixedly connected to the position above the floating strengthening mechanism on the inner surface of the inner cavity of the frustum outer frame, a sound wave emitter is fixedly connected to a middle position of the top of the reflective partition plate, the reflective partition plate is fixedly connected to transfer mechanisms on the front surface and the back surface of the sound wave emitter, and a protecting top cover is fixedly connected to the top of the inner surface of the frustum outer frame. The equipment relates to the technical field of cultivation. The equipment is energized by means of wave fluctuation of a water surface, threatening fishes are dispelled around by sound waves, and the safety of the equipment and the cultured fishes is protected.

Owner:周波

A vehicle control system of a pure electric vehicle and its vehicle structure

InactiveCN104015623BImprove battery lifeEasy to use electricitySpeed controllerElectric devicesElectricityControl system

The invention discloses a vehicle control system of a blade electric vehicle and a blade electric vehicle structure. A battery high-voltage insulation detection unit and a high-voltage loop interlocking unit are introduced into a high-voltage safety management module, and a vacuum brake assisting module is set, so that the electricity consumption and safety properties of the vehicle are largely improved. An energy recovery unit is implanted in a drive management system, recoverable energy is generated when the vehicle slides or brakes, the energy utilization rate is largely improved, and the cruising capacity of the vehicle is improved. Meanwhile, the vehicle is driven by a rear axle, a drive motor is connected with the rear axle by directly inserting the motor, an intermediary transmission mechanism is omitted, and the structure is more compact; intermediary losses can also be reduced, and the transmission efficiency is higher. The utilization rate of a battery can be effectively increased, so that the cruising capacity of the vehicle is higher.

Owner:苏州市京达环卫设备有限公司

Diamond nv magnetometer with integrated odmr functional components and its manufacturing process

ActiveCN108983121BFor maximum integrationEfficient collectionMagnitude/direction of magnetic fieldsMicro nanoManufacturing technology

The invention discloses an ODMR functional part integrated diamond NV magnetometer and a manufacturing technology thereof, and belongs to the fields of solid state atom magnetometers and micro nano processing. A block-shaped diamond prepared with an NV color center ensemble is edged and shaped into a step-shaped diamond, a multi-layer medium combined reflective film is prepared in the upper surface of the diamond in a film growth technology, a multi-layer medium combined cutoff filtering film is prepared in the bottom, the two types of optical functional films wrap a diamond medium to form a light tripping structure, an annular microwave antenna is prepared on the light tripping structure with the diamond as the main body, a light through hole is cut, a laser diode and a photodiode are microfabricated, and the integrated NV magnetometer is realized. The total light tripping cavity structure and system modulation photon collecting functional parts are designed by taking the diamond as the core, the sensitivity of the solid atom magnetometer can be maximized, and the size of the device is reduced.

Owner:ZHONGBEI UNIV

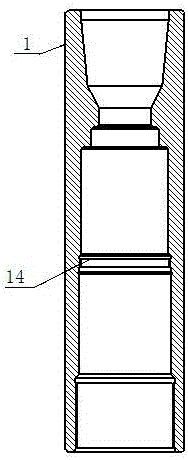

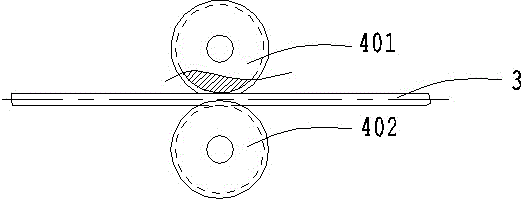

Direct drive engaging and disengaging device of washing machine

ActiveCN102051790BReduce weightReduce volumeOther washing machinesTextiles and paperImpellerDrive motor

Owner:HAIER GRP CORP +2

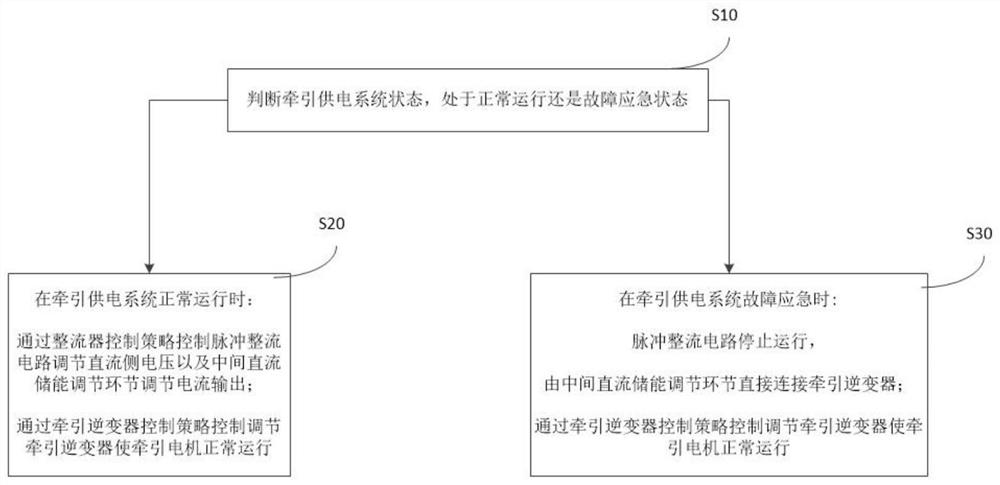

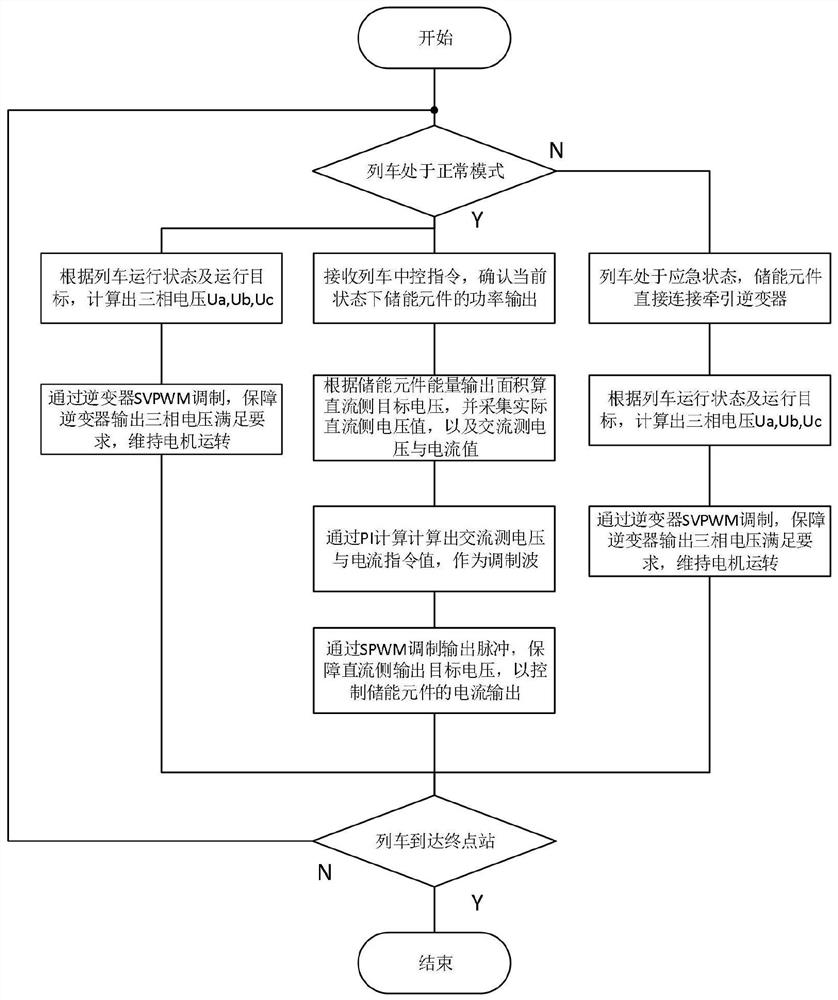

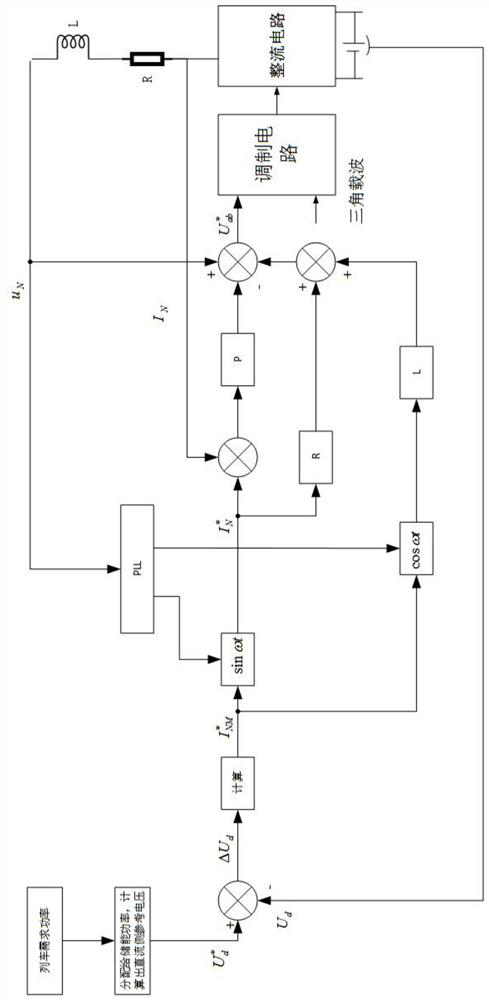

Train emergency energy storage power supply topological structure and control method thereof

ActiveCN111959530AImprove emergency performanceIncrease installed capacityAC motor controlElectric locomotivesElectric machineTraction transformer

The invention discloses a train emergency energy storage power supply topological structure and a control method thereof. The train emergency energy storage power supply topological structure comprises a traction transformer, a pulse rectifying circuit, an intermediate DC energy storage adjusting link and a traction inverter. The pulse rectifying circuit is connected with a traction network through the traction transformer; the intermediate DC energy storage adjusting link is connected between the pulse rectifying circuit and the traction inverter, and the pulse rectifying circuit controls thevoltage of the intermediate DC energy storage adjusting link to control the energy output of the emergency energy storage power supply. The output end of the traction inverter is connected to a traction motor, and the traction motor is controlled to operate through the traction inverter. According to the invention, the defects of high cost, more devices and lower efficiency in the traditional topology scheme can be solved; cost can be effectively saved, emergency energy storage power supply installation capacity is increased, operation efficiency is improved, train emergency capacity is enhanced, and passenger safety is guaranteed.

Owner:SOUTHWEST JIAOTONG UNIV +1

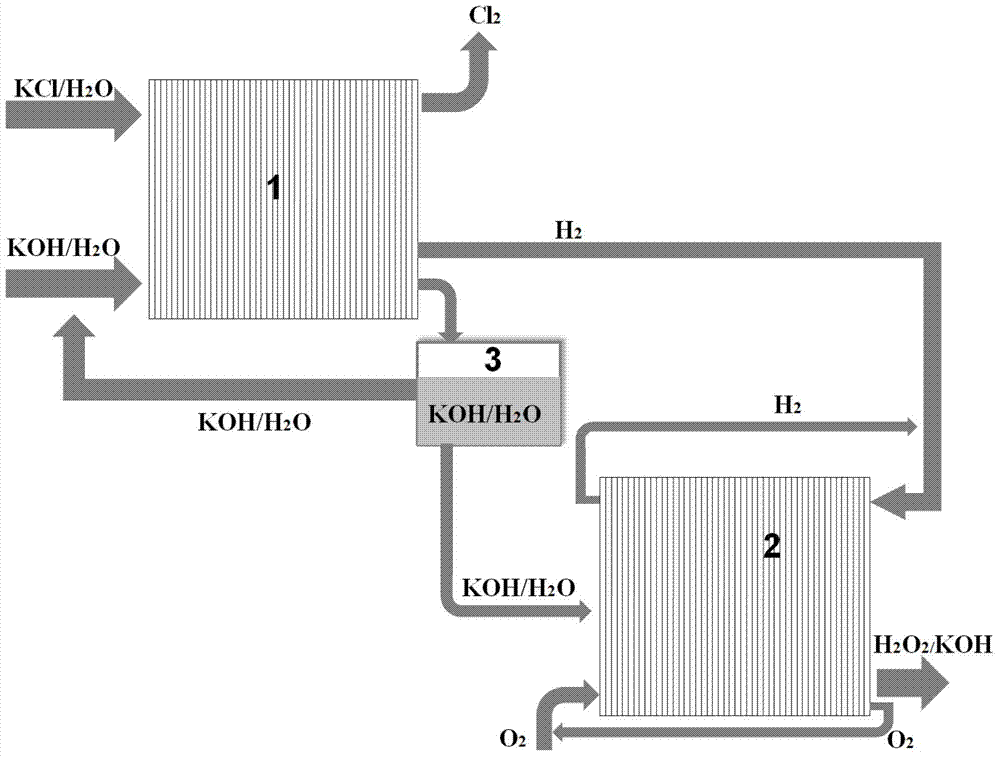

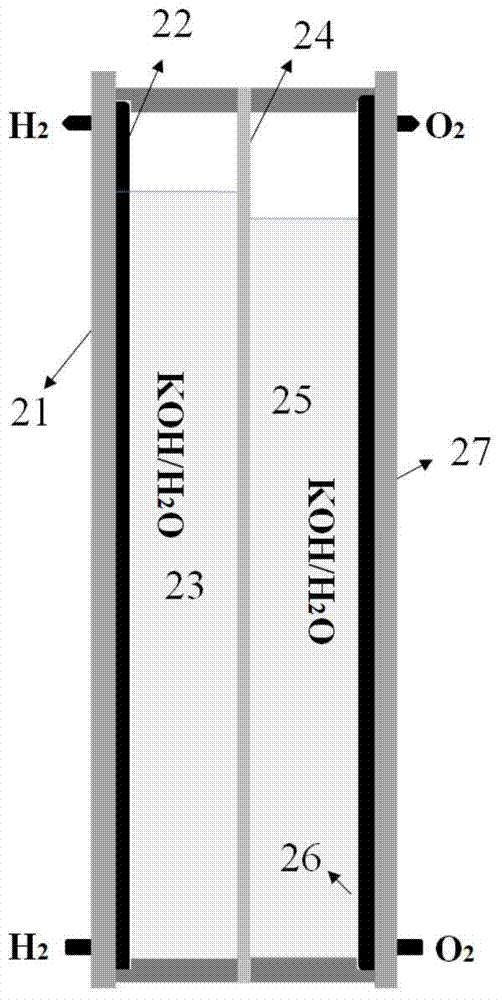

Chemical oxygen-iodine laser chemical raw material regeneration method

InactiveCN104711633AShort production processReduce intermediate lossElectrolysis componentsElectrogenerative processesCompound (substance)Aqueous solution

The present invention relates to a chemical oxygen-iodine laser chemical raw material regeneration method, wherein an electrolysis technology and a fuel cell technology are combined to make the aqueous solution of the chemical oxygen-iodine laser product potassium chloride or sodium chloride and oxygen be subjected to two-step conversion so as to obtain the chemical raw materials such as the chlorine gas and the alkali hydrogen peroxide solution, such that the chemical oxygen-iodine laser chemical raw material regeneration is achieved, wherein the obtained chemical raw materials are required by the chemical oxygen-iodine laser. The regeneration method of the present invention is applicable for on-site regeneration and recycling of the chemical oxygen-iodine laser chemical raw material.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Internal combustion engine and transmission system

PendingCN114352403AReduce in quantitySimple structureInternal combustion piston enginesCrankInternal combustion engine

The invention belongs to the technical field of engines, and particularly relates to an internal combustion engine and a transmission system.The internal combustion engine comprises a stator, a rotor, an ignition system and a fuel supply system.The rotor is rotatably arranged in the stator, a driving structure is arranged between the rotor and the stator, and the ignition end of the ignition system is fixed to the stator and extends to the driving structure; the driving structure does work and drives the rotor to rotate in the stator, and the fuel supply system penetrates through the stator to supply fuel to the driving structure. The transmission system comprises the internal combustion engine. According to the internal combustion engine and the transmission system, a combination of a piston and a crank connecting rod mechanism is replaced by the rotor, the whole engine structure is effectively simplified, the number of high-speed moving parts is reduced, the failure rate in the using process is reduced, the structure is simple, maintenance is simpler even if faults occur, and disassembly and assembly are convenient.

Owner:温向含

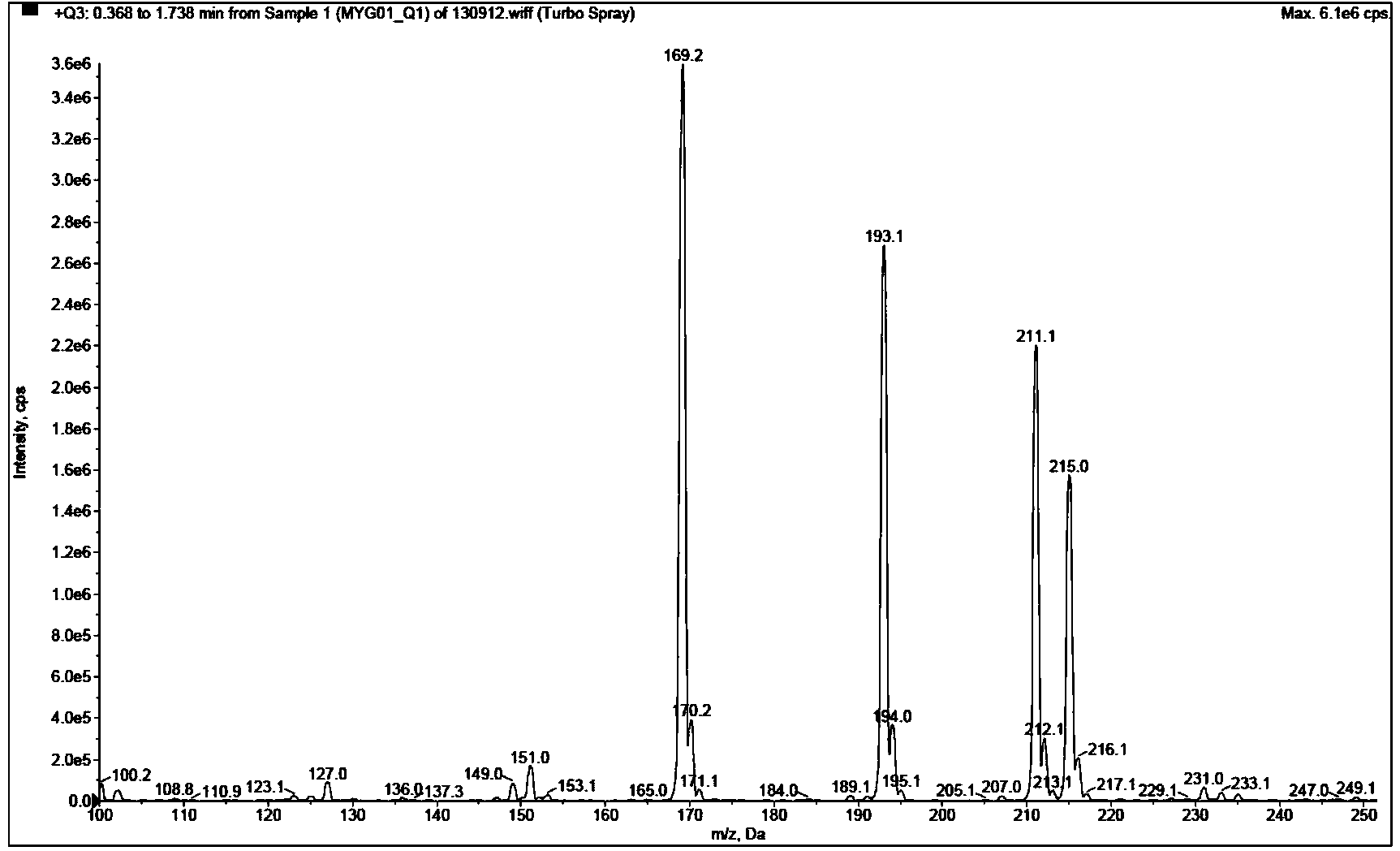

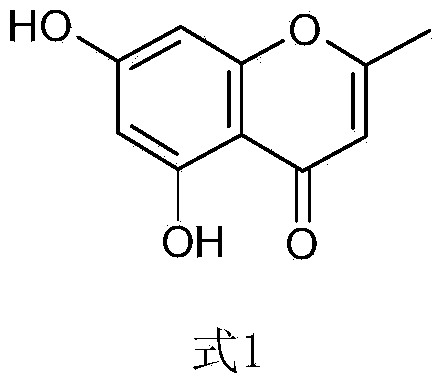

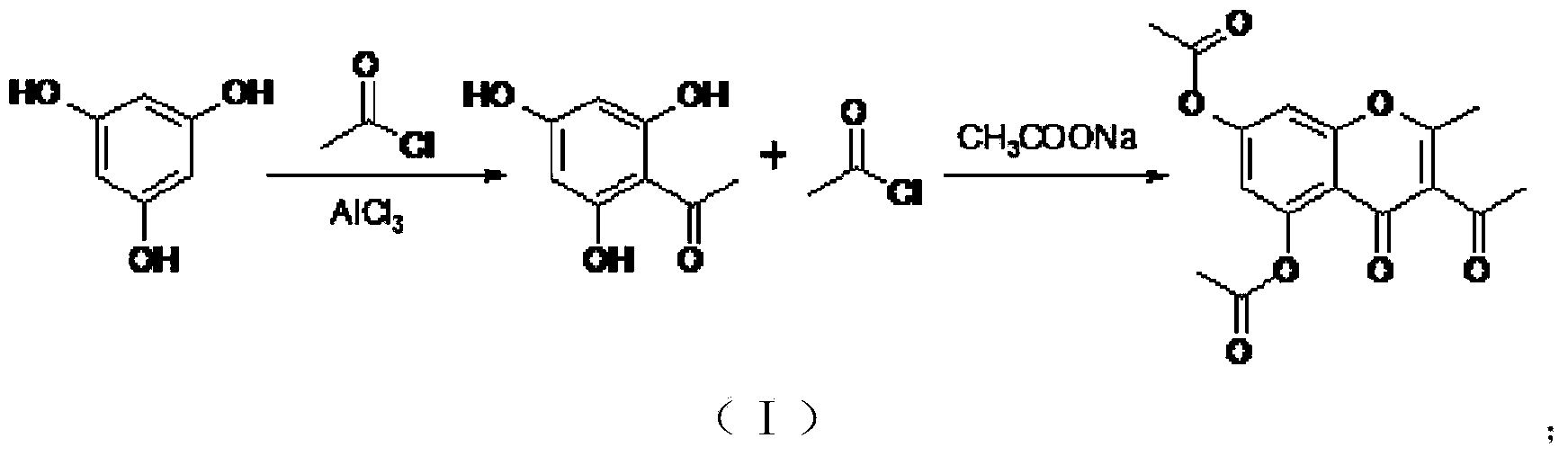

Chemical preparation method of compound 2-methyl-5,7-dihydroxy chromone

The invention provides a chemical preparation method of a compound 2-methyl-5,7-dihydroxy chromone. The chemical preparation method comprises the following steps: by mainly adopting phloroglucinol and acetyl chloride as raw materials, firstly synthesizing 2,4,6-trihydroxy acetophenone by using Lewis acid as a catalyst in an organic solvent system; then replenishing acetyl chloride and a condensation catalyst namely anhydrous sodium acetate, further performing condensation with generated 2,4,6-trihydroxy acetophenone, and performing 'one-pot reaction' to obtain 2-methyl-3-acetyl-5,7-diacetoxyl chromone; and finally, removing acetyl and acetoxyl of 2-methyl-3-acetyl-5,7-diacetoxyl chromone by virtue of soda boiling to obtain a target product namely 2-methyl-5,7-dihydroxy chromone. The method provided by the invention is simple and easily-available in adopted raw material, can simplify the reaction steps, and has the advantages of low cost, high yield, mild reaction condition, applicability in industrial production, environmental protection and the like.

Owner:GUANGDONG SYNYOO NEW MATERIAL

Pulse Jet Longitudinal Impactor

The invention relates to a pulsed-jet longitudinal impactor. The lower end of a pump upper cover and the upper end of a pump outer cover are connected through a thread, the lower end of the pump upper cover is connected with a central rotor, the upper end of a pump middle shaft is provided with a thread, and the pump middle shaft is fixed at the lower end of the central rotor and sits on a lower cover plate through a boss; the lower cover plate is fixed inside the lower end of the pump outer cover and fixes the central rotor and the pump middle shaft inside the pump outer cover at the same time, the pump outer cover is fixed inside a main pup joint by a fixing cover nut, a valve is fixed at the lower end of the pump middle shaft, and an upper valve plate is fixed inside the valve through a fixing bolt; a lower valve plate is fixed at the upper end of an impact valve which is provided with a thread, the impact valve is in threaded connection with an impact joint which is fixed inside a hexagonal sleeve, the upper portion of the main pup joint is connected with an upper drill column while the lower portion of the same is connected with the hexagonal sleeve, and the impact valve is fixed above the hexagonal sleeve and provided with a passageway inside. The pulsed-jet longitudinal impactor is few in middle structure, low in energy consumption, large in impact force and long in service life.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

automatic washing machine

InactiveCN104141212BReduce weightReduce volumeOther washing machinesTextiles and paperImpellerDrive motor

The invention discloses a full-automatic washing machine comprises an outer tub, an inner basket, an impeller and a drive device, wherein the drive device comprises at least two rotors and at least one stator, one rotor is connected with an inner basket shaft, and the other rotor is connected with an impeller shaft; the drive device adopts a variable-frequency direct drive motor; the rotors, the stator, the inner basket shaft and the impeller shaft are coaxially arranged, the inner basket shaft is hollow, and the impeller shaft is arranged in the inner basket shaft; and during washing of the washing machine, the impeller and the inner basket rotate in the same direction or in reverse directions, or either of the impeller and the inner basket rotates, and the impeller and the inner basket rotate in the same direction at the same speed during spinning. According to the full-automatic washing machine, the two rotors are connected with the inner basket shaft and the impeller shaft respectively, the inner basket and the impeller are driven to rotate respectively by the two rotors, the weight, size and cost of a drive system are reduced to a great extent by means of the structure, and the transmission efficiency and stability are improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Hot forging composite processing device and hot forging composite processing method

ActiveCN103264283BImprove performanceImprove machining accuracyOther manufacturing equipments/toolsEngineeringMachining

The invention provides a hot forging composite machining device and method. The device comprises a drive mechanism, a transmission mechanism, a heating mechanism, a blanking mechanism, a hot forging forming mechanism, a discharging mechanism and an induction mechanism. The transmission mechanism is connected with the drive mechanism, the heating mechanism is arranged between the feeding mechanism and the transmission mechanism, the hot forging forming mechanism is arranged below the blanking mechanism and connected with the discharging mechanism, and transmission variables of the transmission mechanism are transmitted to the blanking mechanism through the induction mechanism. The hot forging composite machining method comprises the steps that a) the drive mechanism drives the transmission mechanism to transfer hot forging materials to the heating mechanism, and the transmission variables are transmitted to the blanking mechanism through the induction mechanism; b) the hot forging materials are heated; c) the heated hot forging materials are transferred to the blanking mechanism for blanking; d) forging forming is performed, and e) discharging is performed. According to the hot forging composite machining device and method, unmanned operation and smooth transition of work sections during hot forging are guaranteed, the stable performance of the work sections is guaranteed, automation is achieved, the machining efficiency is high, and molded parts are stable in quality.

Owner:RIFENG ENTERPRISE GRP CO LTD +1

Honeysuckle black tea making process

The invention belongs to the technical field of tea leaves, relates to a honeysuckle black tea making process, and the honeysuckle black tea making process is simple to operate and low in cost, the made honeysuckle black tea product is uniform in quality, the quality is greatly improved, and the economic benefit is greatly improved.

Owner:涉县以岭燕赵中药材有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com