Method for extracting hesperidin from citrus to prepare hesperetin

A technology of hesperidin and hesperetin, applied in the field of hesperetin, can solve the problems of waste, complicated process conditions, increased cost of hesperetin, etc., and achieve the effects of reducing intermediate loss and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] a) Preparation of reference substance solution: Accurately weigh 0.01g hesperetin reference substance, accurate to 0.0001g, dissolve it with mobile phase, transfer it into a 100mL volumetric flask, add mobile phase to constant volume to 100mL, and filter the obtained solution with a 0.45μm filter membrane Filter and use the filtrate for later use.

[0043] b) Preparation of sample solution: Accurately weigh 0.01g sample, accurate to 0.0001g, dissolve it with mobile phase, transfer it into a 100mL volumetric flask, add mobile phase to make the volume to 100mL, filter the obtained solution with a 0.45μm filter membrane, and filter the filtrate spare.

[0044] c) Determination: Under the above-mentioned chromatographic conditions, measure the reference substance solution and the sample solution respectively, and record the main peak area.

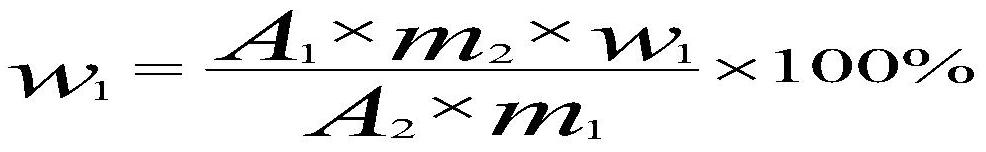

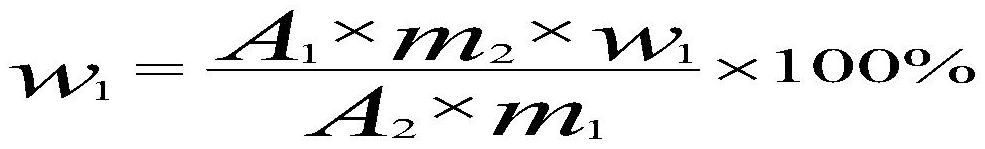

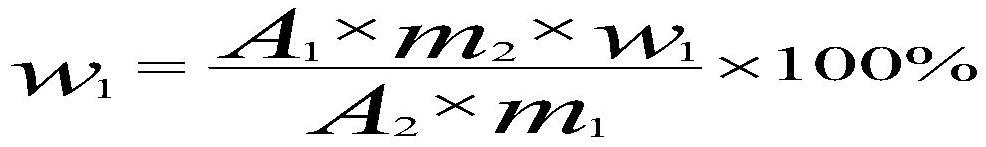

[0045] d) Calculation of results: mass fraction w of hesperetin content 1 Calculated according to the following formula

[0046] ...

Embodiment 1

[0061] Example 1: Grind the dried citrus, pass through a 100-mesh sieve, weigh 100kg of powder, add solvent water, the ratio of solid to liquid (w / v) is 1:10, adjust the pH of the solution to 11.0, and place it in a homemade Extract in the ultrasonic countercurrent extraction device for 120min, filter, and collect the extract; after extracting twice, combine the extract, concentrate the combined extract to 1 / 3 of the volume of the original extract, adjust the concentrated extract Liquid pH to 3.0, settling for 8 hours, filtering to collect the precipitate, washing the precipitate with pure water to neutrality and drying into powder, weighing to obtain citrus crude extract, adding water to the weighed citrus crude extract, the ratio of solid to liquid (w / v) is 1:40, add amylase (1:20), pectinase (1:20), protease (1:20), rhamnosidase (1:30), β-glucoside Enzyme (1:30) for hydrolysis reaction, the reaction conditions are: temperature 50°C, pH 5.5, time 5h, after the reaction is co...

Embodiment 2

[0062] Example 2: Grind the dried citrus, pass through a 100-mesh sieve, weigh 100kg of powder, add solvent water, the ratio of solid to liquid (w / v) is 1:15, adjust the pH of the solution to 11.0, and place it in a homemade Extract in an ultrasonic countercurrent extraction device for 120min, filter, collect the extract, extract twice, combine the extract, concentrate the combined extract to 1 / 4 of the volume of the original extract, and adjust the concentrated extract Liquid pH to 3.0, settling for 8 hours, filtering to collect the precipitate, washing the precipitate with pure water to neutrality and drying into powder, weighing to obtain citrus crude extract, adding water to the weighed citrus crude extract, the ratio of solid to liquid (w / v) is 1:50, add amylase (1:30), pectinase (1:30), protease (1:30), rhamnosidase (1:40), β-glucoside Enzyme (1:40) for hydrolysis reaction, the reaction conditions are: temperature 50°C, pH 5.5, time 5h, after the reaction is completed, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com