Chemical oxygen-iodine laser chemical raw material regeneration method

A technology of oxygen iodine chemistry and chemical raw materials, which is applied in the field of regeneration of chemical raw materials of oxygen iodine chemical lasers, can solve the problems of inconvenient transportation and storage, difficult to effectively guarantee the supply of raw materials, high cost, etc., and achieves low intermediate loss, short production process, The effect of reducing the need for substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

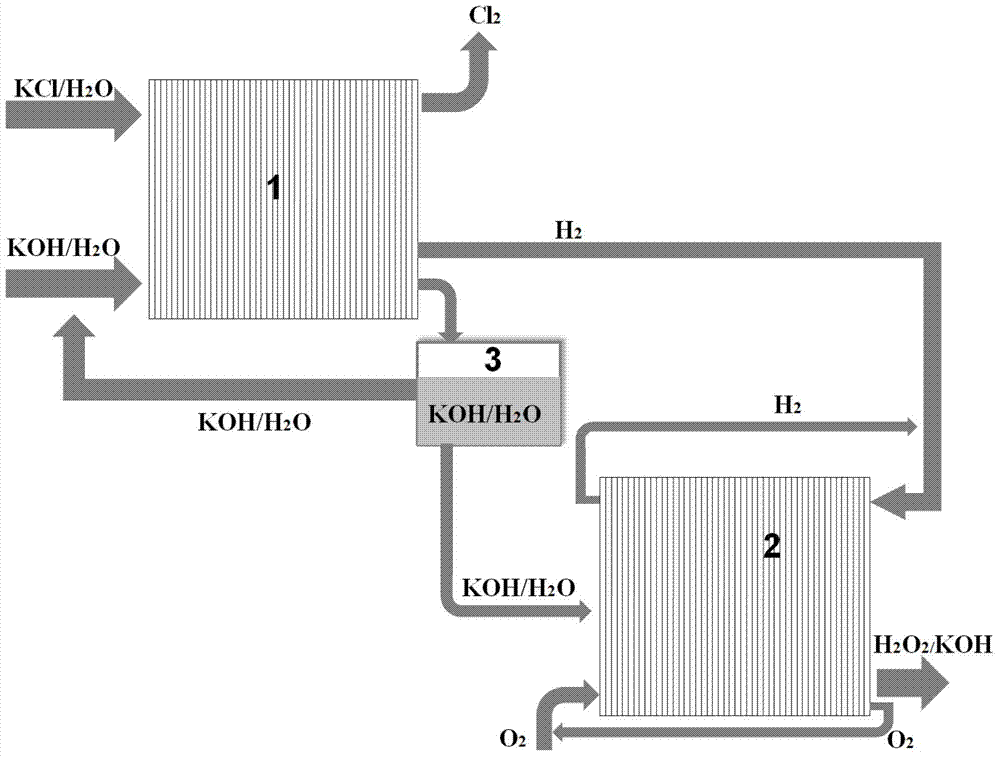

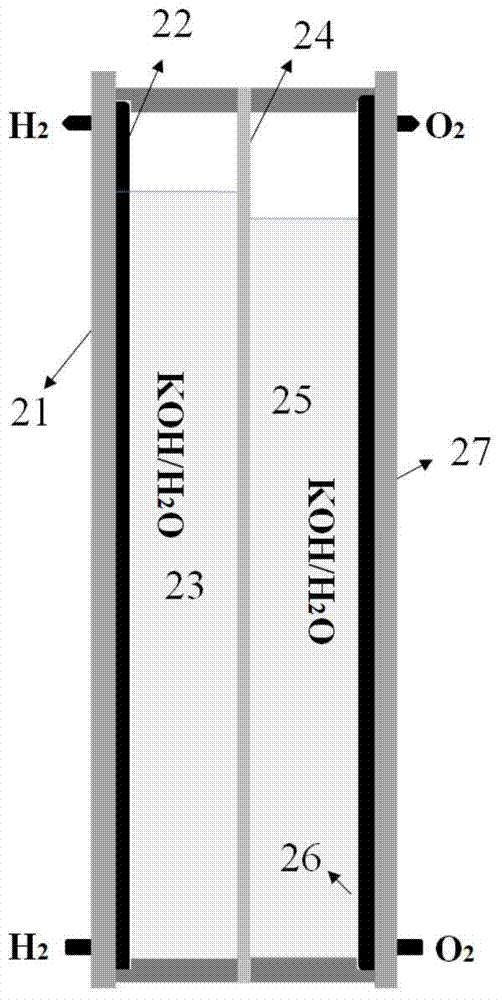

[0027] The selected chlor-alkali electrolytic cell 1 is a conventional electrolytic cell structure in the chlor-alkali industry, that is, the anode is a DSA electrode, the cathode is a nickel mesh, the diaphragm is a DuPont Nafion membrane, and the cell is a single-section structure. Put the 2mol / L potassium chloride aqueous solution obtained through the separation of the oxygen-iodine chemical laser reaction product into the potassium chloride liquid storage tank, and input the potassium chloride aqueous solution to the cathode side of the chlor-alkali electrolyzer 1, and place the potassium chloride aqueous solution on the cathode side of the chlor-alkali electrolyzer 1 Input 2mol / L aqueous solution of potassium hydroxide to the side, and conduct electrolysis through direct current. During electrolysis, chlorine gas is generated on the anode side. The chlorine gas obtained from the anode side of the above-mentioned chlor-alkali electrolyzer is dried and then put into the chl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com