Manufacturing and mounting method and auxiliary mounting device for reinforcement cage in pile hole

A technology of inner reinforcement cage and installation method, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of large dynamic friction factor of reinforcement weight, increased labor, mechanical construction period, hoisting, and installation difficulty, etc. The probability of accident, the effect of saving equipment and easy quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

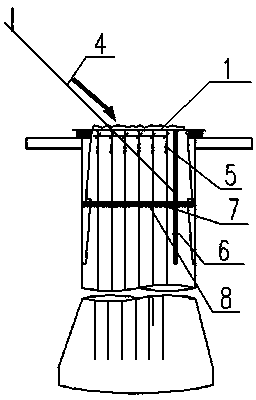

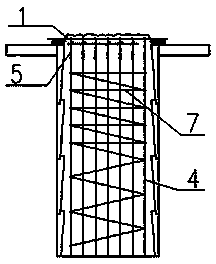

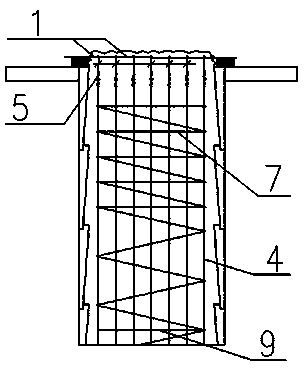

[0018] A method for making and installing a reinforcement cage in a pile hole of the present invention is as follows: the method adopts a polygonal mounting frame with legs provided at each end to be placed at the pile hole that has been dug, and the polygonal mounting frame is provided with a The reference point corresponding to the main reinforcement, the reference point and the angle of the main reinforcement relative to the center of the pile hole are the same, and then the processed outer stirrups are placed in the hole pile at intervals of 2m to 3m through soft ropes, and Bind the outer stirrups on the polygonal mounting frame with a soft rope to fix the outer stirrups, and then place a guide groove with a hook at the reference point of the polygonal mounting frame and fix it. One end of the main re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com