Counter bracing device for installation of pouring formwork of concrete walls

A technology for concrete slabs and formwork, which is applied to the joints of formwork/formwork/work frames, the preparation of building components on site, and construction, which can solve the problems of wasting raw materials, manpower and material resources, etc., to save resources and ensure Quality, cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

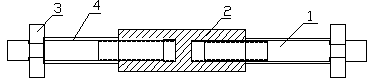

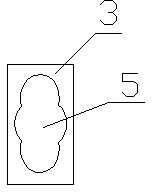

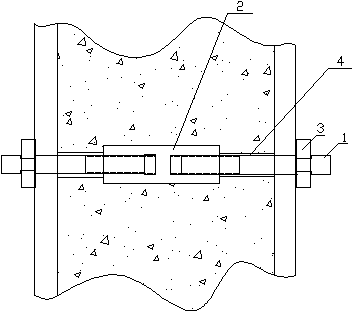

[0011] The tensioning device used for the installation of concrete slab wall pouring formwork is composed of two wall-penetrating screws, sleeves, joints and clamping plates. The wall-penetrating screw and the wall-penetrating screw are connected by joints. On the screw, the end of the wall-through screw connected to the joint is provided with threads, and the two ends of the joint are provided with internal thread holes matching the threads on the wall-through screw, the wall-through screw and the joint are threaded, and the other end of the wall-through screw There is a radial annular groove and an axial square adjustment inner hole. The depth of the square adjustment inner hole is less than the distance from the annular groove to the end of the wall screw. It is matched with the wall-through screw, and the two ends of the card hole are matched with the thin neck formed by the annular groove of the wall-through rod. The sleeve pipe is a plastic pipe, and the inner diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com