A cutter automatic adjustment device for ceramic raw material granulator

A ceramic raw material, automatic adjustment technology, applied in clay preparation devices, manufacturing tools, chemical instruments and methods, etc., can solve the problems of low cutting and grinding efficiency of ceramic raw materials, short service life of granulator, affecting production efficiency, etc. The effect of maintenance and replacement, simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

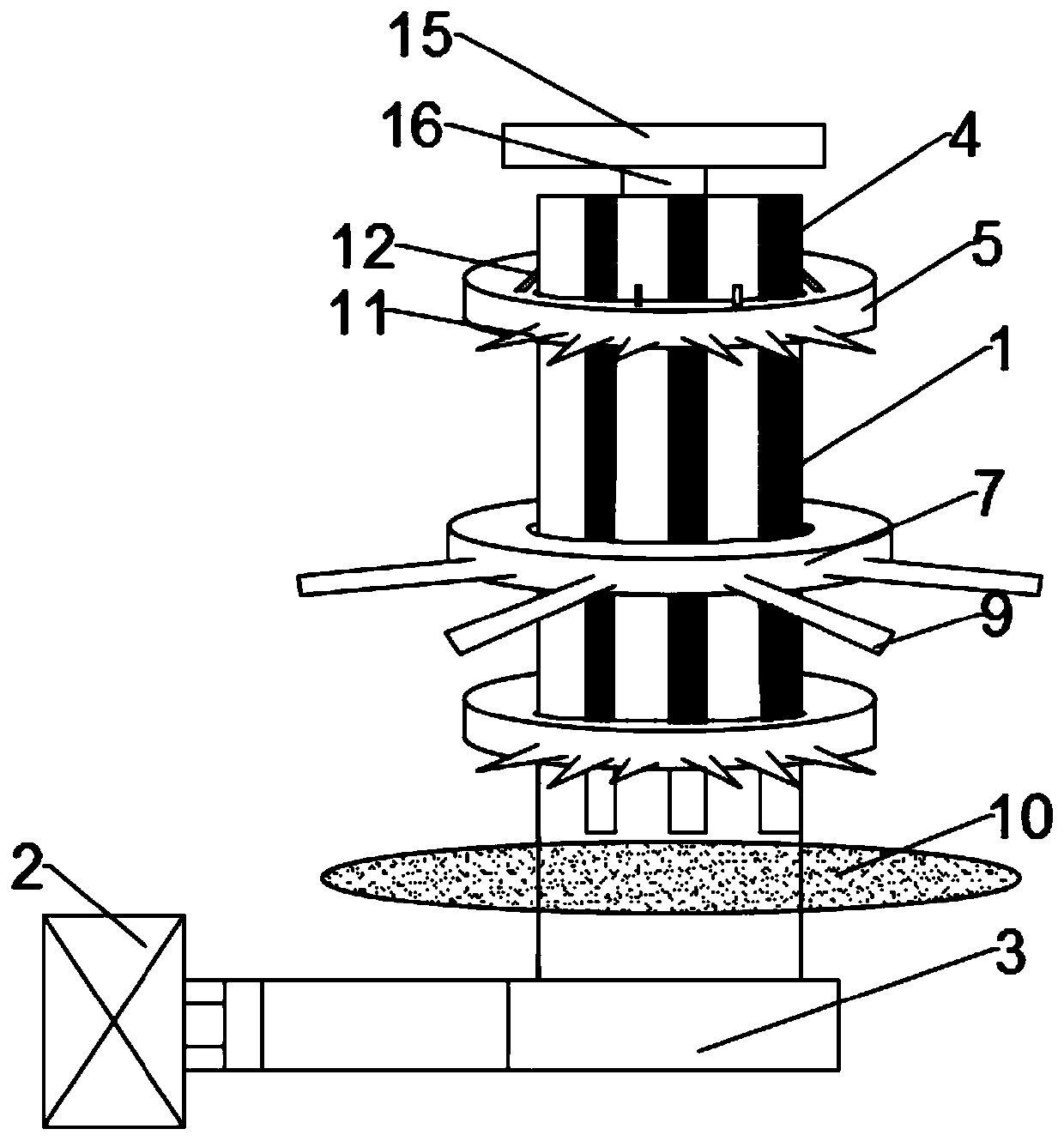

[0022] Such as figure 1 As shown, the present invention provides an automatic cutter adjustment device for a ceramic raw material granulator, which includes a rotating shaft 1 and a motor 2. A pulley 3 is sleeved on the rotating shaft 1, and the pulley 3 is driven by the motor 2. Through the belt drive, the motor 2 drives the rotating shaft 1 through the pulley 3, which can effectively use the space of the present invention, and the use of this type of rotation does not cause energy loss and achieves a better cutting effect.

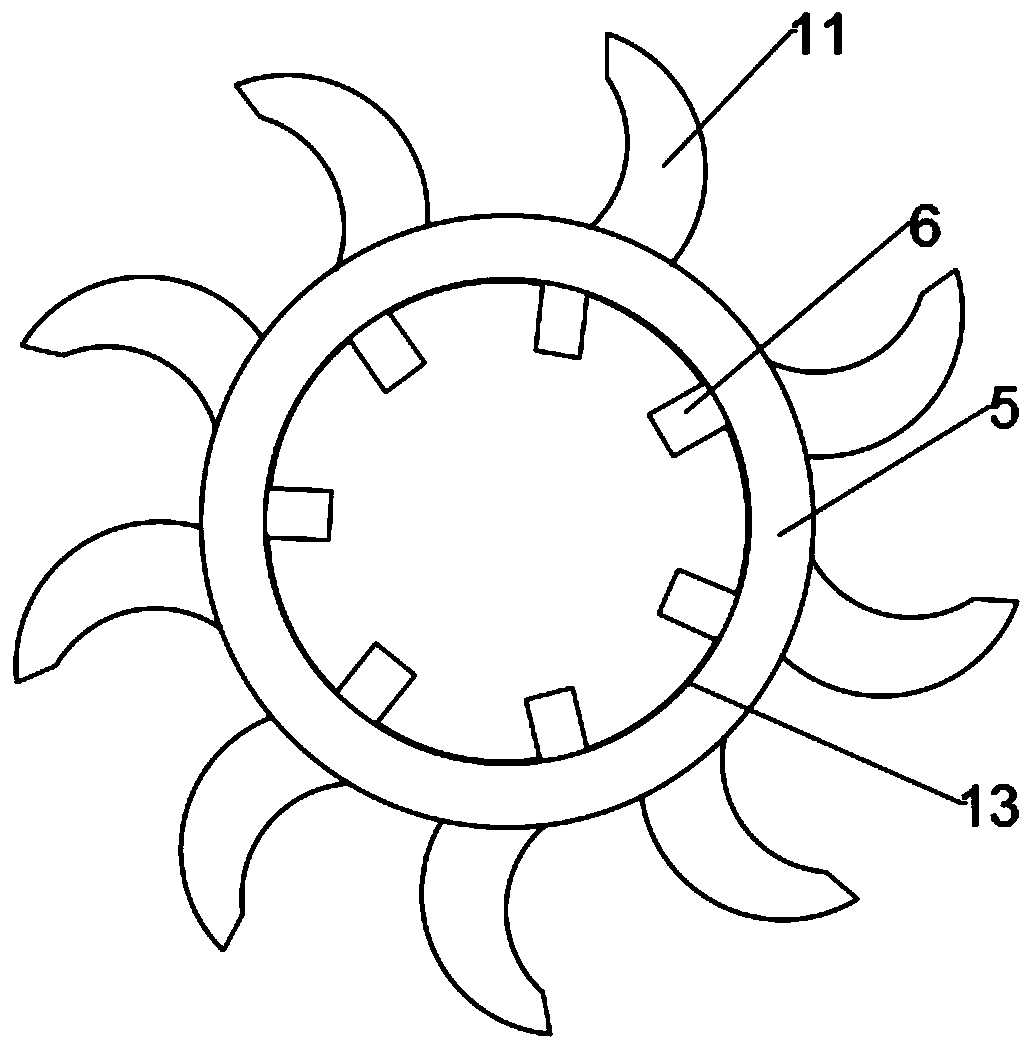

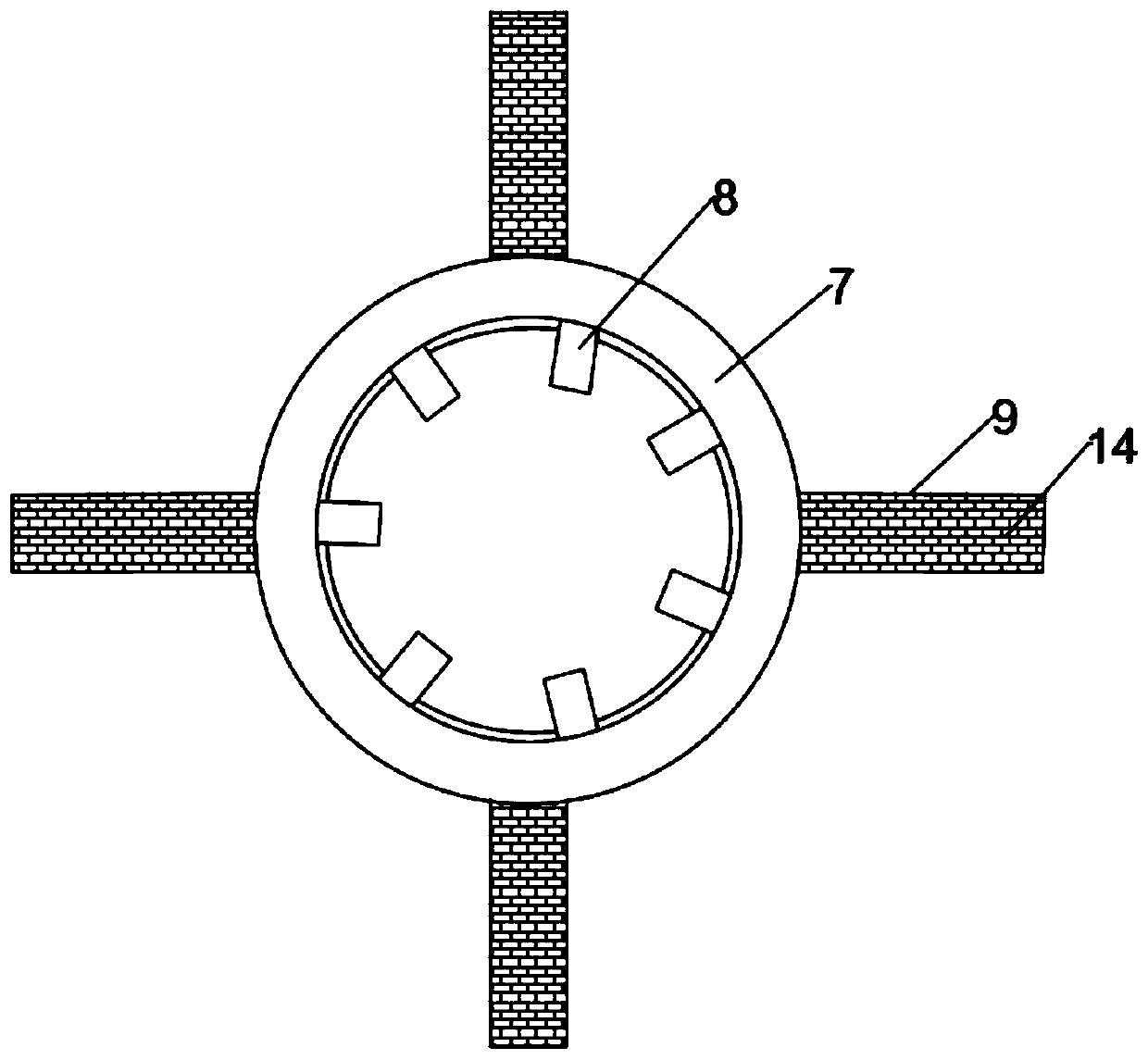

[0023] Such as figure 1 with figure 2 As shown, the rotating shaft 1 is provided with a number of grooves 4, the grooves 4 are evenly spaced, and the center of the cross section of the rotating shaft 1 is taken as the symmetrical point, and the limiting block 5 is sleeved on the rotating shaft 1. There are two limiting blocks 5, and the side section of the limiting block 5 is a circular ring structure, the inner diameter of the limiting block 5 is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com