Multi-phase fault-tolerant permanent magnet synchronous motor disk rotor

A permanent magnet synchronous motor, disc rotor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of poor short-circuit current suppression effect, etc., to achieve easy fixation, high electrical and mechanical Reliability, the effect of halving the usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

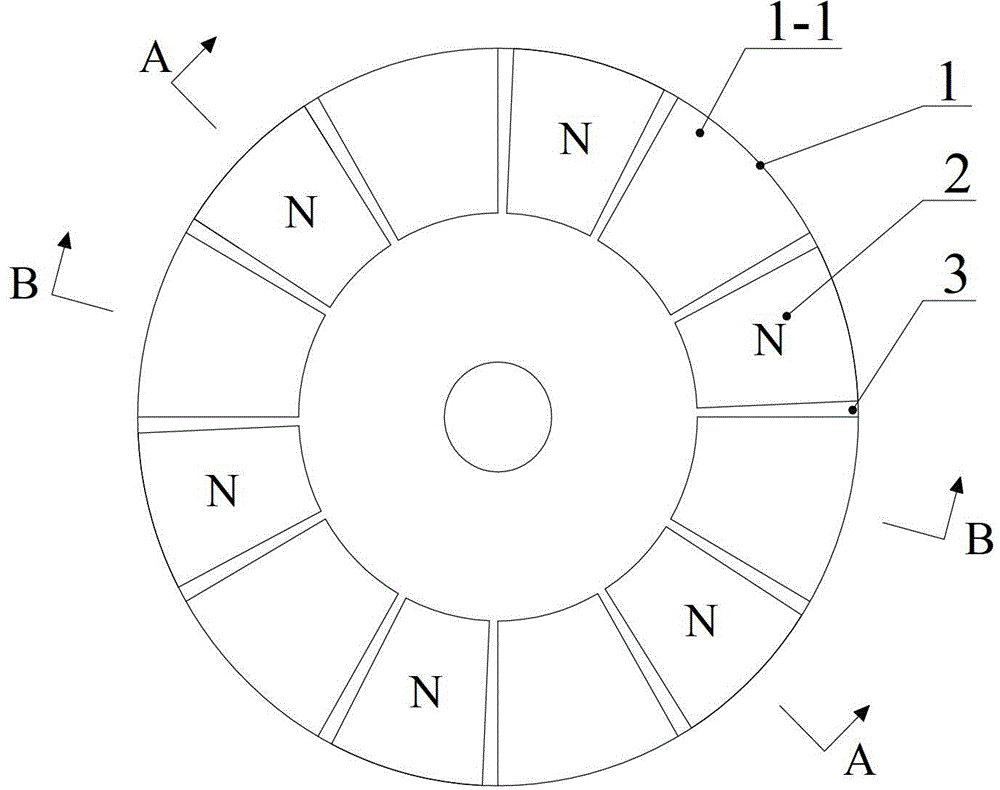

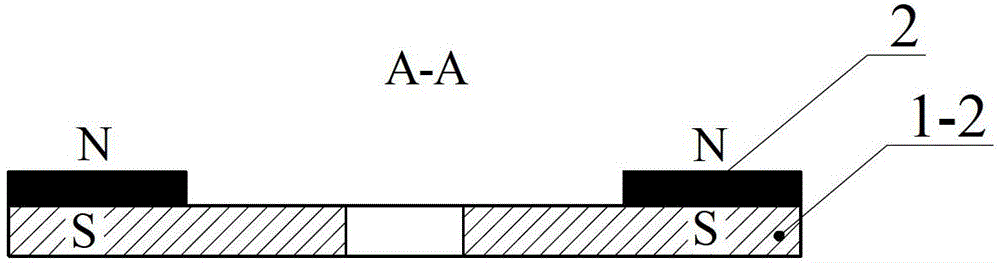

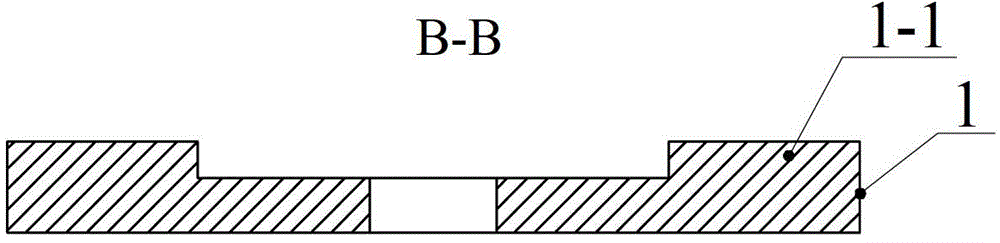

[0014] Specific implementation mode one: the following combination Figure 1 to Figure 7 Describe this embodiment, the multiphase fault-tolerant permanent magnet synchronous motor disk rotor described in this embodiment includes a rotor core 1 and p permanent magnets 2, and the rotor core 1 includes rotor core yokes 1-2 and p rotor core poles 1 -1, there are p rotor core poles 1-1 arranged on the disc surface of the circular rotor core yoke 1-2, and the p rotor core poles 1-1 are evenly arranged along the circumferential direction, every two adjacent rotor core poles A permanent magnet slot 3 is formed between 1-1, and a permanent magnet 2 is embedded in each permanent magnet slot 3. The central angle of the sector of the permanent magnet 2 is less than or equal to the central angle of the sector of the permanent magnet slot 3, and p permanent magnets 2 The polarity of the surface opposite to the stator is the same, and it is magnetized in the axial direction, and p is the num...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment further describes Embodiment 1. The rotor core 1 is made of solid steel or stacked silicon steel sheets.

specific Embodiment approach 3

[0025] Embodiment 3: In this embodiment, Embodiment 1 is further described. The rotor core 1 is made of amorphous ferromagnetic composite material or SMC soft magnetic composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com