Arch-cross-section roadway tunneling support device

A supporting device and roadway technology, which is applied to the mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems of impossible to achieve full-section roof connection, repeated investment in equipment, and loose roof surrounding rock, so as to save the need for advanced The effect of supporting links, reducing repeated investment, and preventing support loopholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

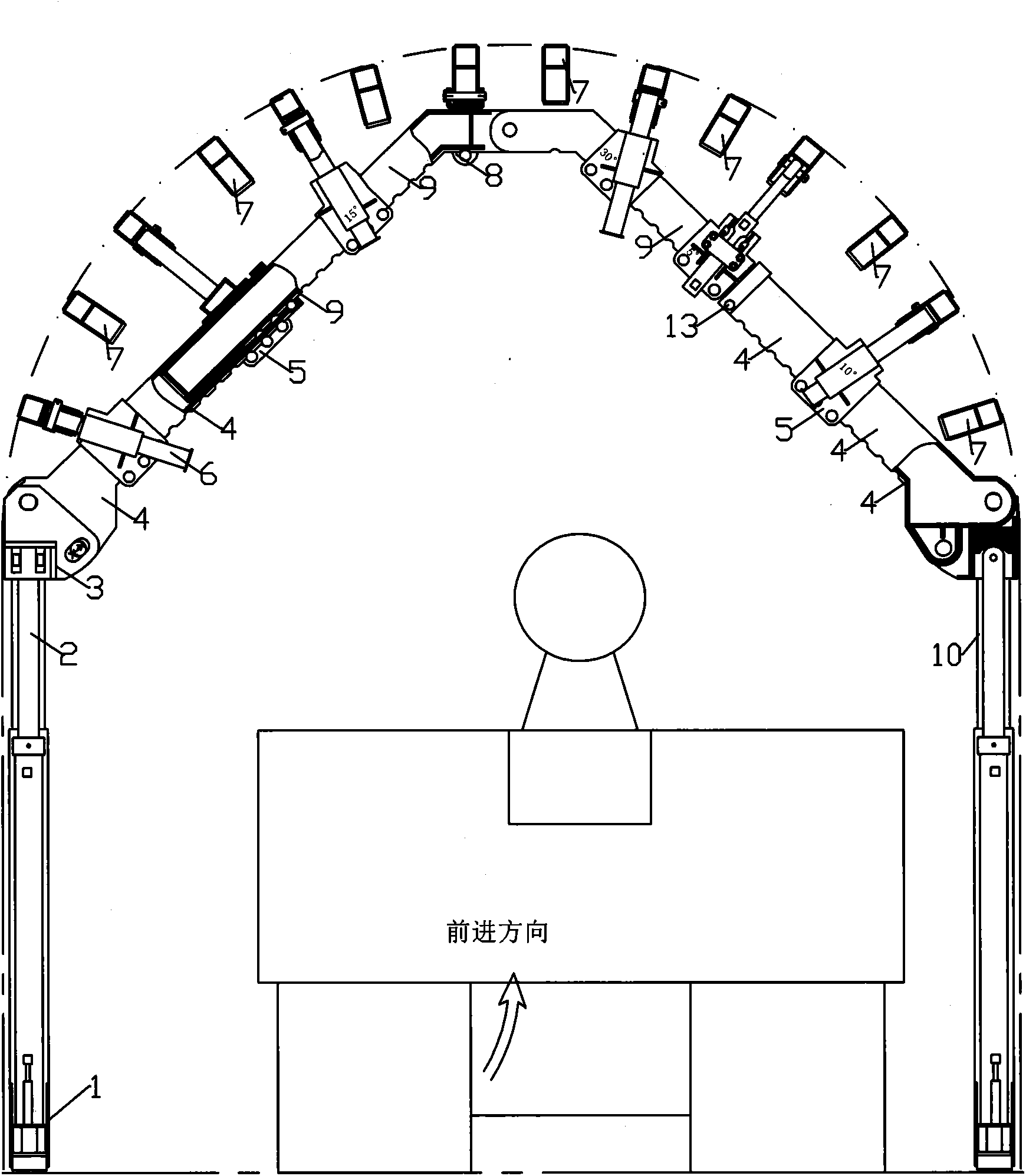

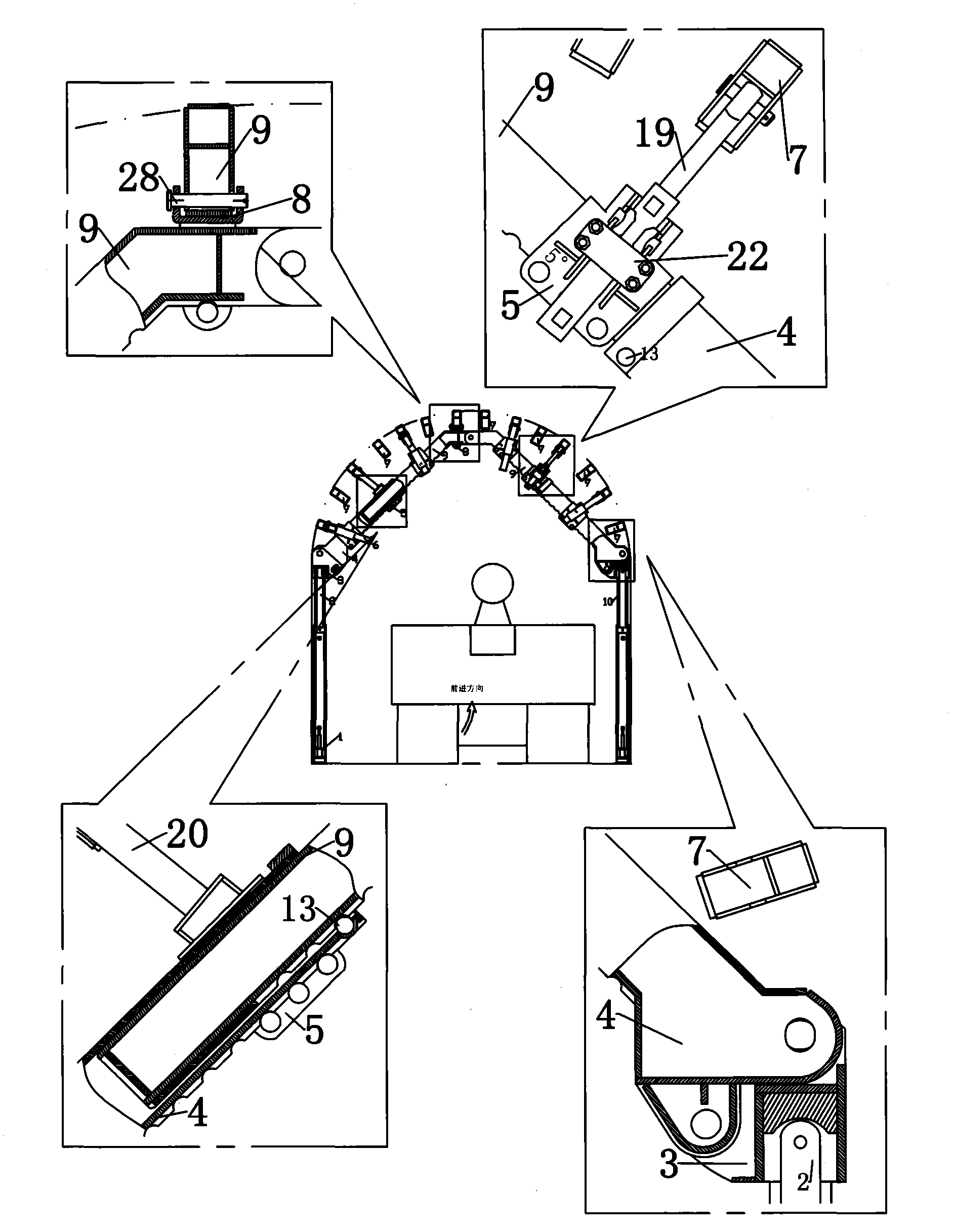

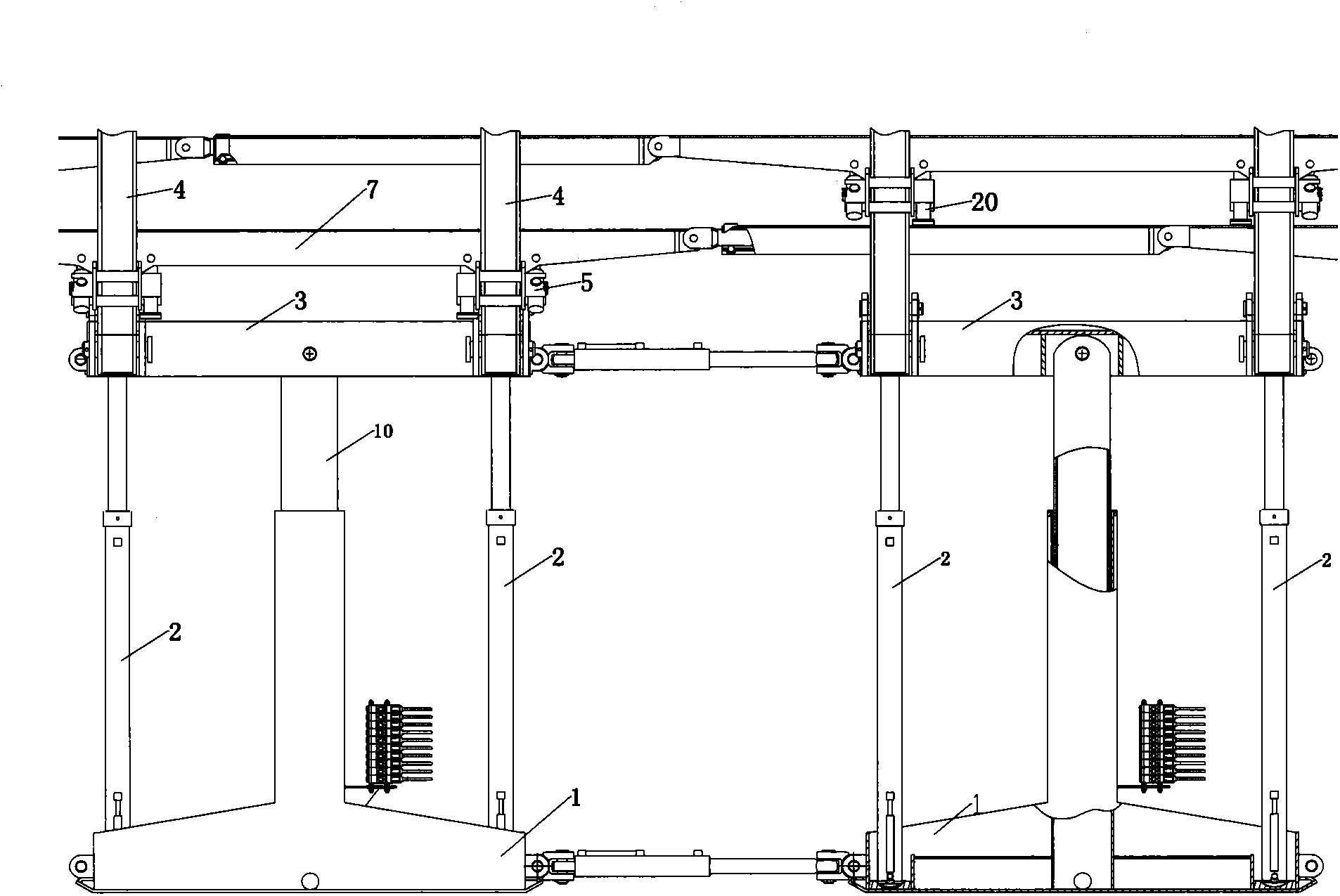

[0022] Such as figure 1 and figure 2 As shown, the support of the arched section roadway support device of the present invention includes a base 1 symmetrically arranged on the left and right sides, and the base 1 is respectively vertically provided with columns 2 along the two sides of the roadway to support the whole support device. Also be provided with vertical vertical beam seat along the roadway both sides on the top, vertical movable vertical beam 16 is installed on the vertical beam seat, the movable vertical beam lower end stretches in the vertical beam seat, the movable vertical beam upper end and along the roadway The top beams 3 arranged vertically and symmetrically on the top of both sides are hinged (the vertical beam mechanism can also be replaced by a planar four-bar linkage); the upper part of the column 2 is supported by a longitudinal top beam 3, and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com