Premixed secondary flame fired civil boiler with furnace basin

A furnace basin and boiler technology, which is used in household stoves/stoves, solid heating fuels, lighting and heating equipment, etc., can solve problems such as air pollution, waste of coal, pollution, etc., to ensure heat exchange efficiency, improve combustion efficiency, avoid Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

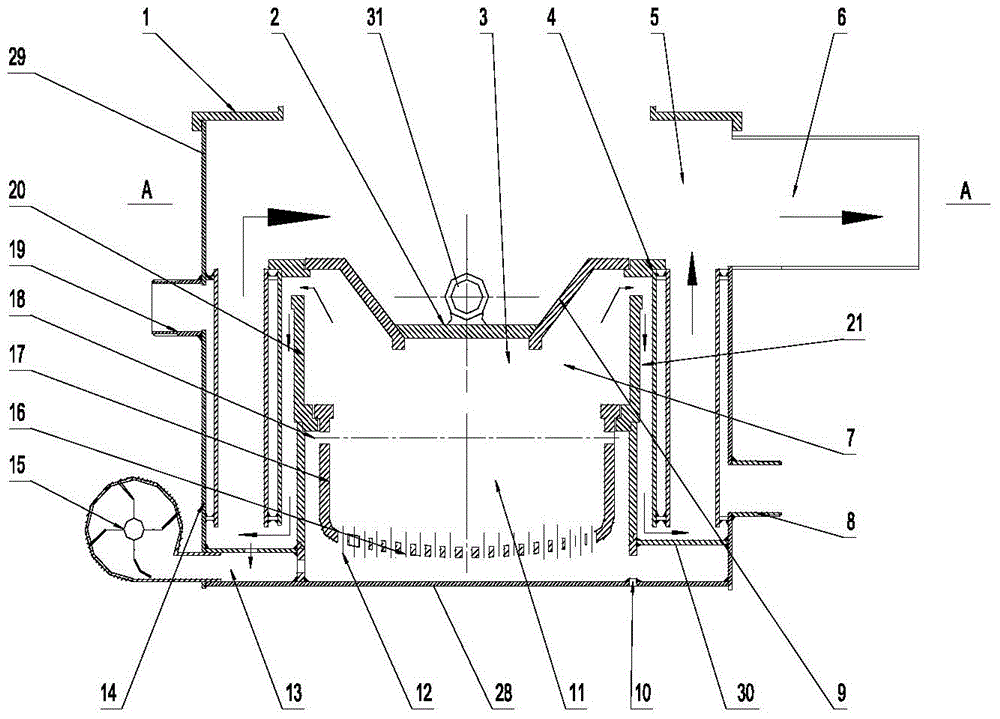

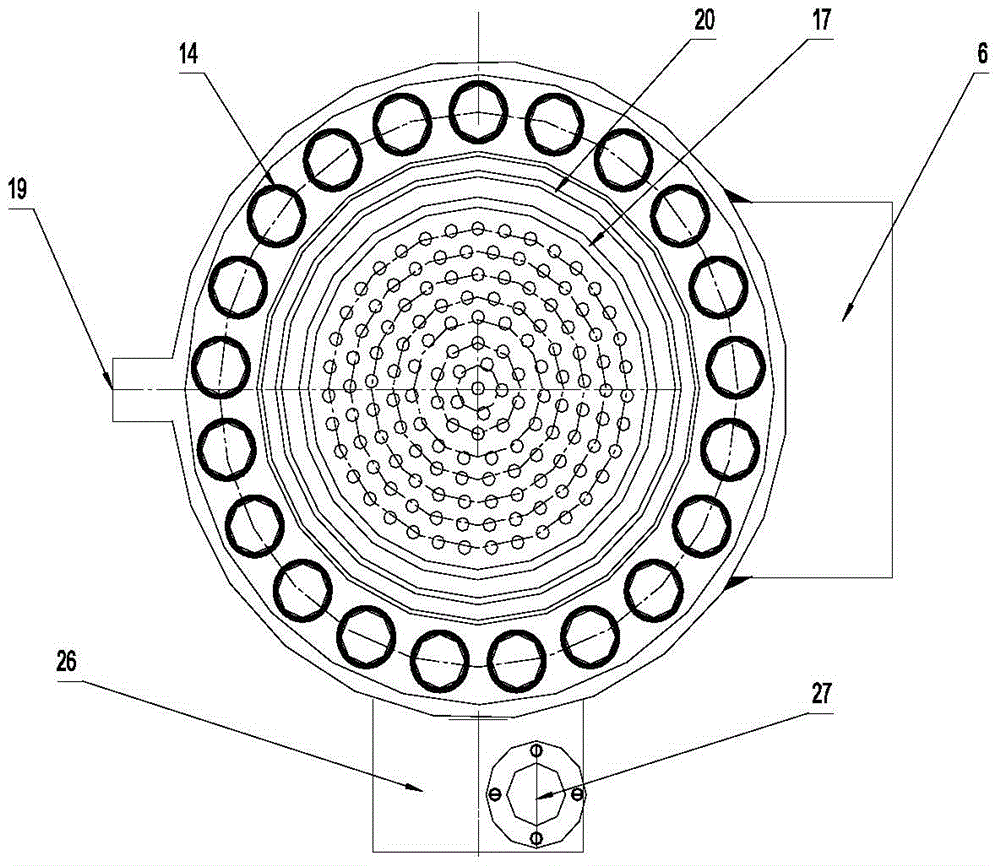

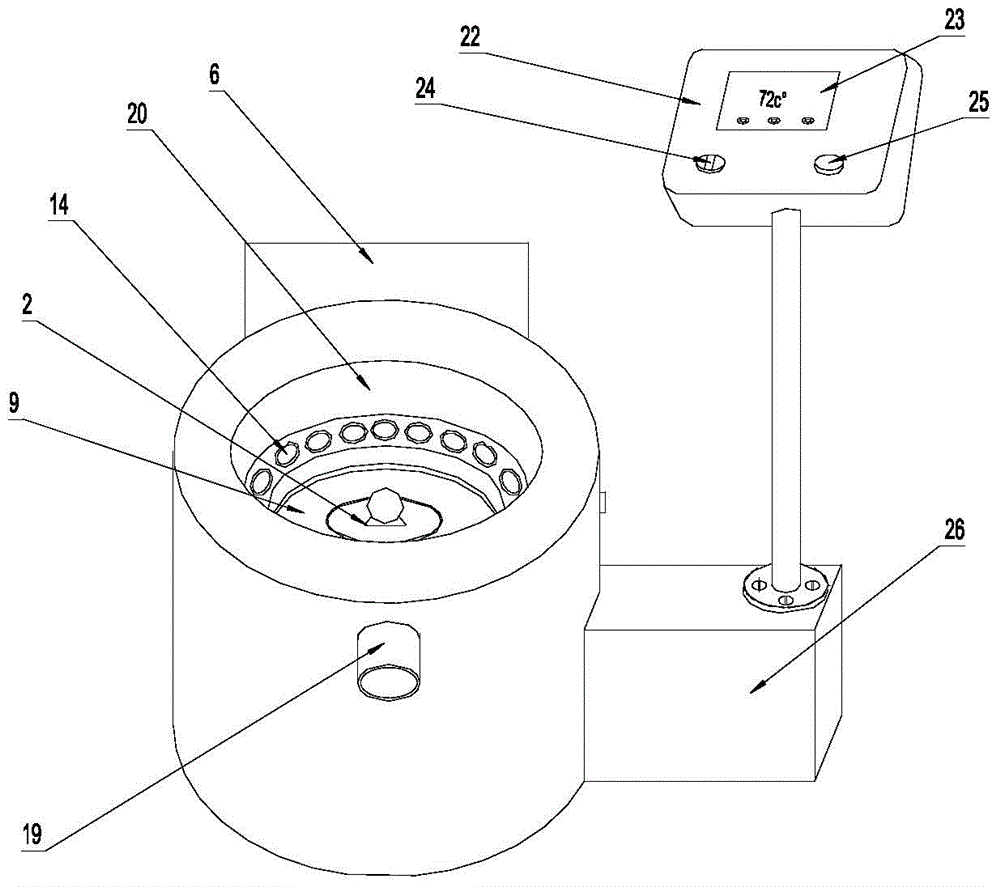

[0014] Depend on Figure 1 to Figure 3 As shown, the premixed secondary fire-injection combustion civil boiler with a furnace basin includes a furnace body 29, a base 28, a water return port 8 and a water outlet 19, a smoke exhaust port 6, and a fan 15. The periphery of the furnace body 29 is welded Fixed on the base 28, the top of the furnace body 29 is covered with an upper furnace cover 1, and the inner circumference of the furnace body 29 is coiled with a heat exchange tube 14, and the heat exchange tube 14 is connected with the water return port 8 and the water outlet on the furnace wall 19 is connected, wherein, the L-shaped upper furnace basin support 30 is arranged at the lower part of the heat exchange tube 14 in the furnace body, and the periphery of the upper furnace basin support 30 is fixed on the furnace wall, and the upper mouth of the upper furnace basin sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com