Swing core type purification energy-saving ventilator

A ventilator, core-type technology, applied in energy-saving heating/cooling, heating mode, climate sustainability, etc., can solve the problems of large pressure and kinetic energy loss, difficulty in balancing the air volume of the two channels, and high failure rate, and achieve a simplified structure. , Improve the utilization of space inside the machine and the effect of high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

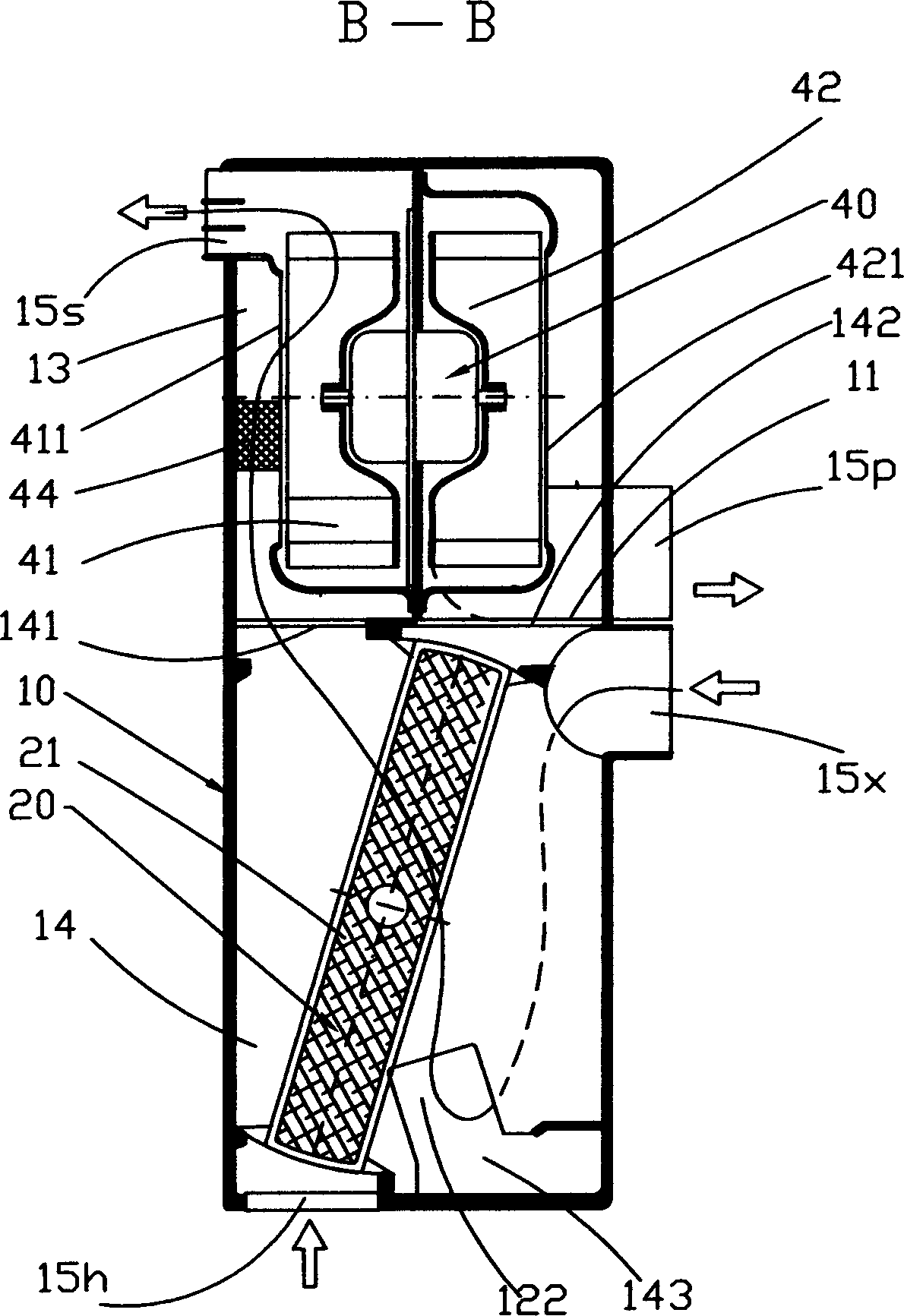

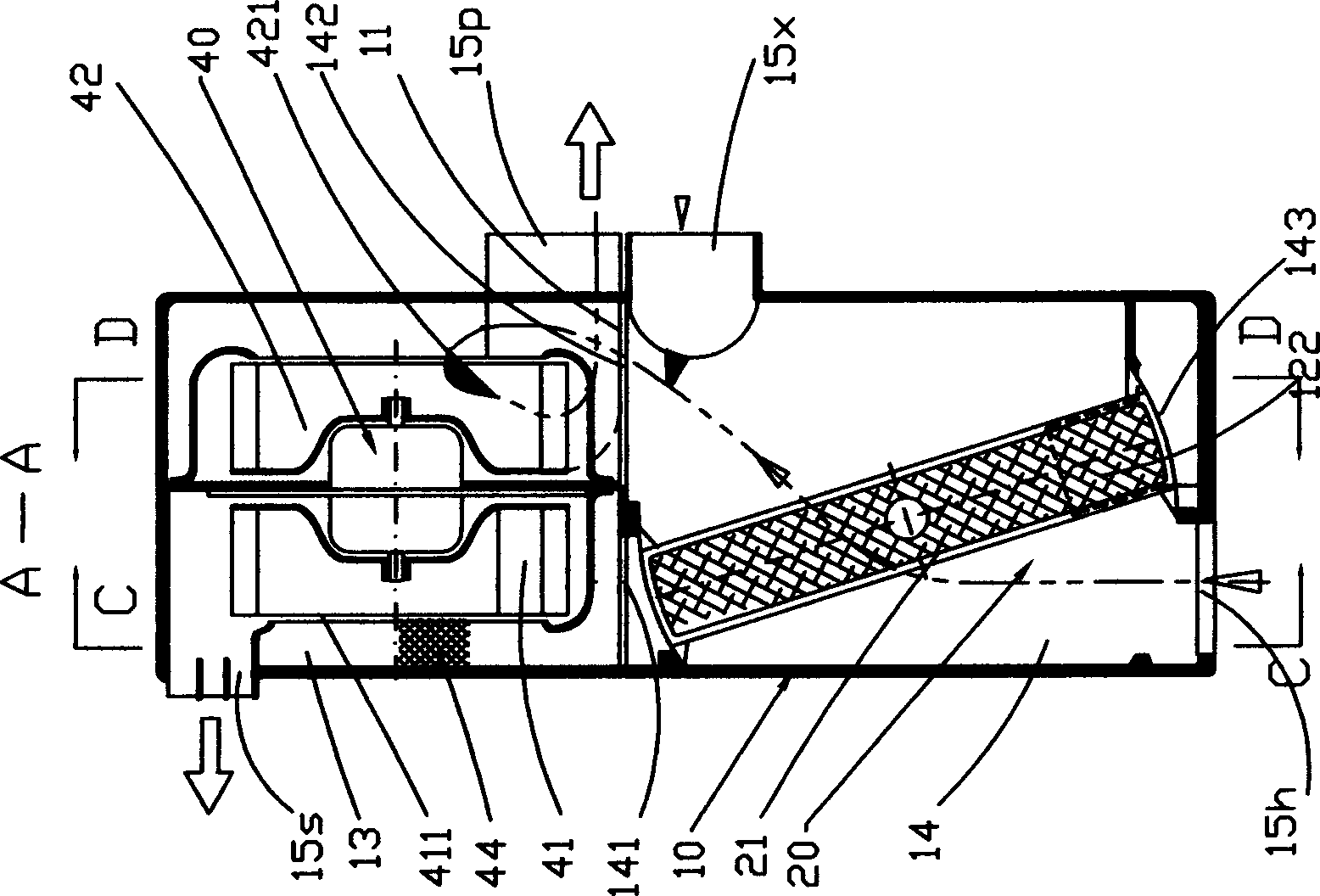

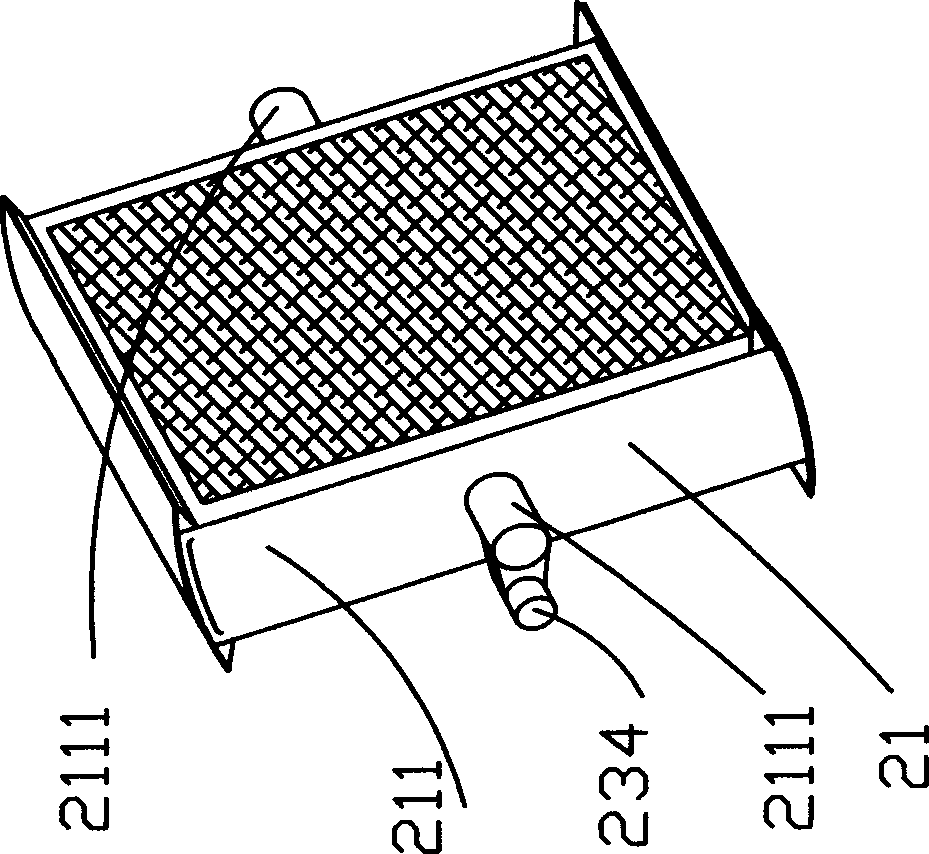

[0035] Embodiment 1 of the present invention is as Figure 1-5 , shown in 10, this example is a kind of basic structure is the pendulum type purifying energy-saving ventilator of single-layer heat exchange core, hangs on the wall and uses, and it comprises the heat exchanger that comprises casing 10, places in the casing 20 and fan device 40; casing 10 is box-shaped, and indoor air return port 15h, air supply port 15s, fresh air port 15x and air exhaust port 15p communicating with the outdoor are arranged on the box wall. The air return port is set at the bottom of the casing, the air supply port is set at the upper part of the front of the casing, the fresh air outlet 15x and the exhaust port 15p are set at the back of the casing, and share a circular or rectangular air duct extending to the outside through the wall hole, such as Figure 10 shown.

[0036] The inner cavity of the casing is divided into a fan chamber 13 and a heat exchange chamber 14 by a transverse partition 1...

Embodiment 2

[0047] Embodiment 2 of the present invention is as image 3 , 6 -10 shown.

[0048] This example is an optimized structure. There are double-layer heat exchange cores in each sub-cavity of the heat exchange chamber, that is, there are four heat exchange cores 21 in the heat exchange chamber 14. The main structure is basically the same as that of Example 1. The main points are the number and arrangement of the heat exchange cores, the driving mechanism, the air duct of the air outlet in the machine, etc.

[0049] The upper wall of the heat exchange chamber 14, that is, the transverse partition 11, has a middle air supply hole 143a, a front row of air holes 148, and a rear row of air holes 145, and the middle air supply hole 143a and the rear row of air holes 145 are connected with the fresh air fan respectively. 41 is directly communicated with the air inlet of the exhaust fan 42, and the front air hole 148 is communicated with the air inlet of the exhaust fan 42 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com