Round tube, tube and fin heat exchanger with streamlined variable amplitude parabolic corrugated fins

A corrugated fin and streamlined technology, which is applied in the field of round tube fin heat exchanger fins, can solve the problems of poor flow linearity and large partial pressure loss of fluid flowing through the side channel of the fin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

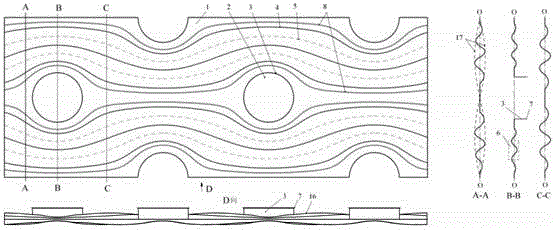

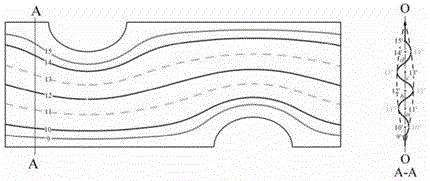

[0020] see figure 1 -2. The present invention includes the circular tube hole 2 on the fin 1 , the ring boss 3 , the stamped out streamlined parabolic convex corrugation 4 , the streamlined parabolic concave corrugation 5 and the corrugated shape 6 . The round pipe holes 2 can be arranged in a fork row or in a straight row. The height of the annular boss 3 is equal to the pitch of the fins, which plays the role of positioning the fins. The top of the ring boss 3 is turned outwards with a flanging 7, which is convenient for the fins to pass through the tube and the fins to be positioned. The streamlined parabolic convex corrugations 4 (solid lines) and the streamlined parabolic concave corrugations 5 (dotted lines) are alternately distributed between the corrugated area boundaries 8 according to the flow function value of the corrugated area boundaries 8, and are respectively about the vertical and horizontal directions of the circular pipe hole 2. The center line is symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com