Tool for dismounting break-brake spring

A technology of opening and removing springs, applied in the direction of calibrating/finding protection devices, etc., can solve the problems of inconvenient installation and carrying, unfavorable use, inconvenient disassembly and assembly, etc., and achieves the effect of simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

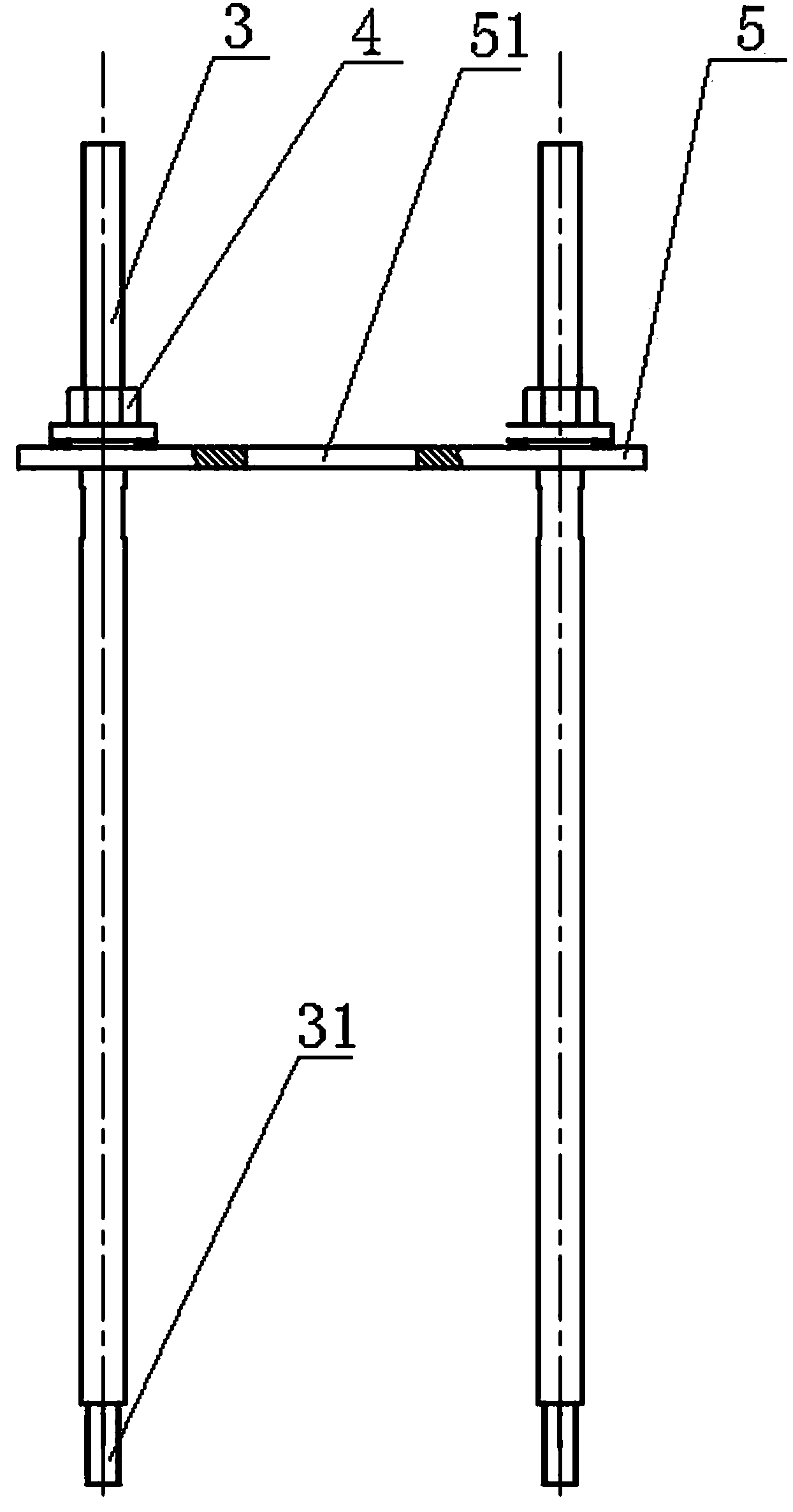

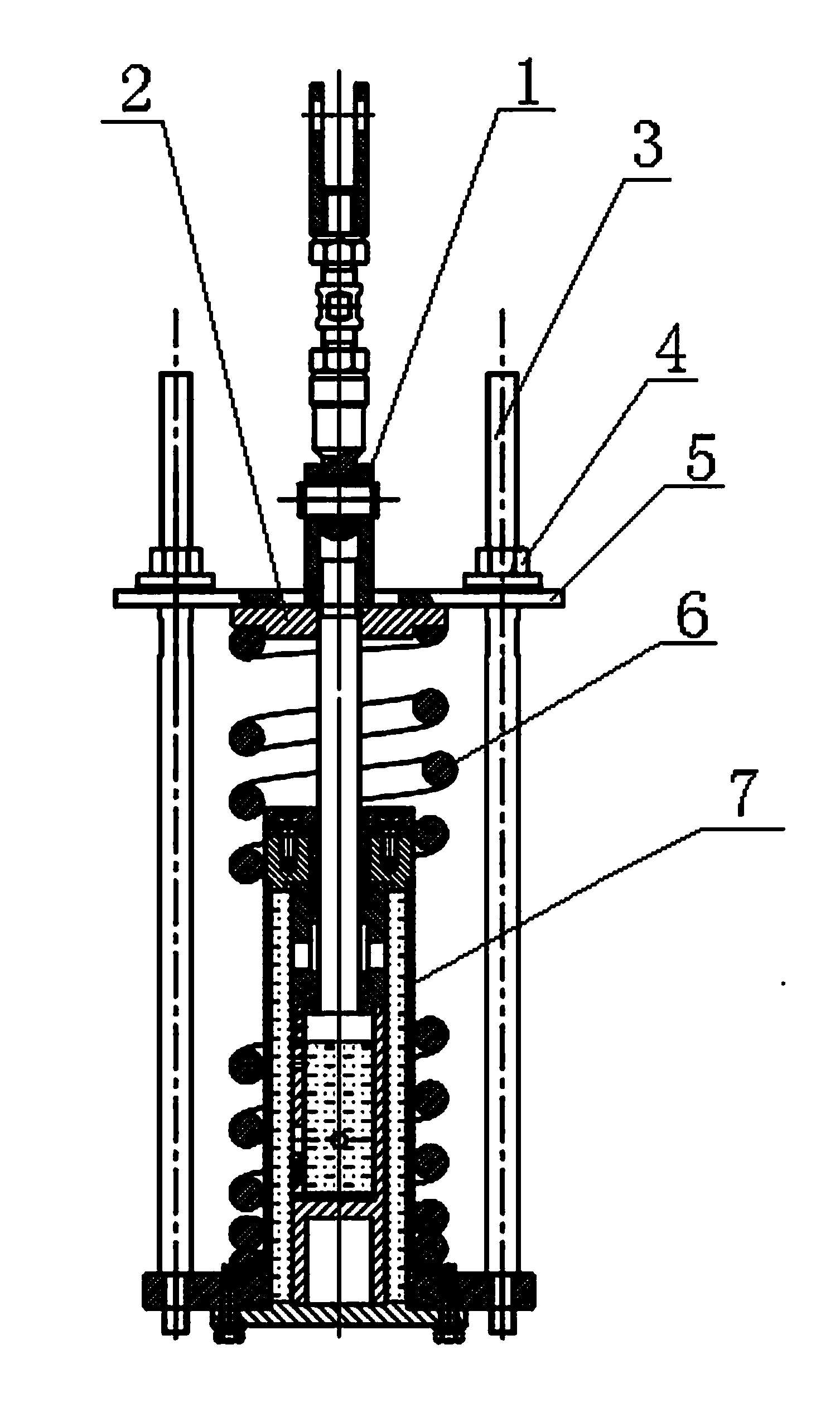

[0012] The embodiment of the frock for dismounting the opening spring of the present invention: as Figure 1 ~ Figure 2 As shown, the tooling includes two poles 3 for fixed connection with the spring housing of the opening spring device. The two poles 3 are symmetrically arranged on both sides of the opening spring device. The compression direction of the gate spring extends, and the support rod is provided with a compression spring support plate 5, which has a bottom surface for pressing on the compression spring plate 2 to compress the opening spring 6 and a top surface away from the bottom surface. The compression spring support plate 5 is provided with the connection sleeve 1 for locking the compression spring support plate 2 to pass through the connection sleeve perforation of the compression spring support plate 5 from the bottom surface of the compression spring support plate to the top surface, and the pole 3 is provided with an outer Threaded screw rod, the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com