Ultrahigh-precision positioning rotary worktable with zero-clearance cam and worm transmission effect

A rotary table and worm drive technology, applied in the direction of manufacturing tools, large fixed members, metal processing equipment, etc., can solve the problems affecting the positioning accuracy of the rotary table and the positioning accuracy of the CNC rotary table

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

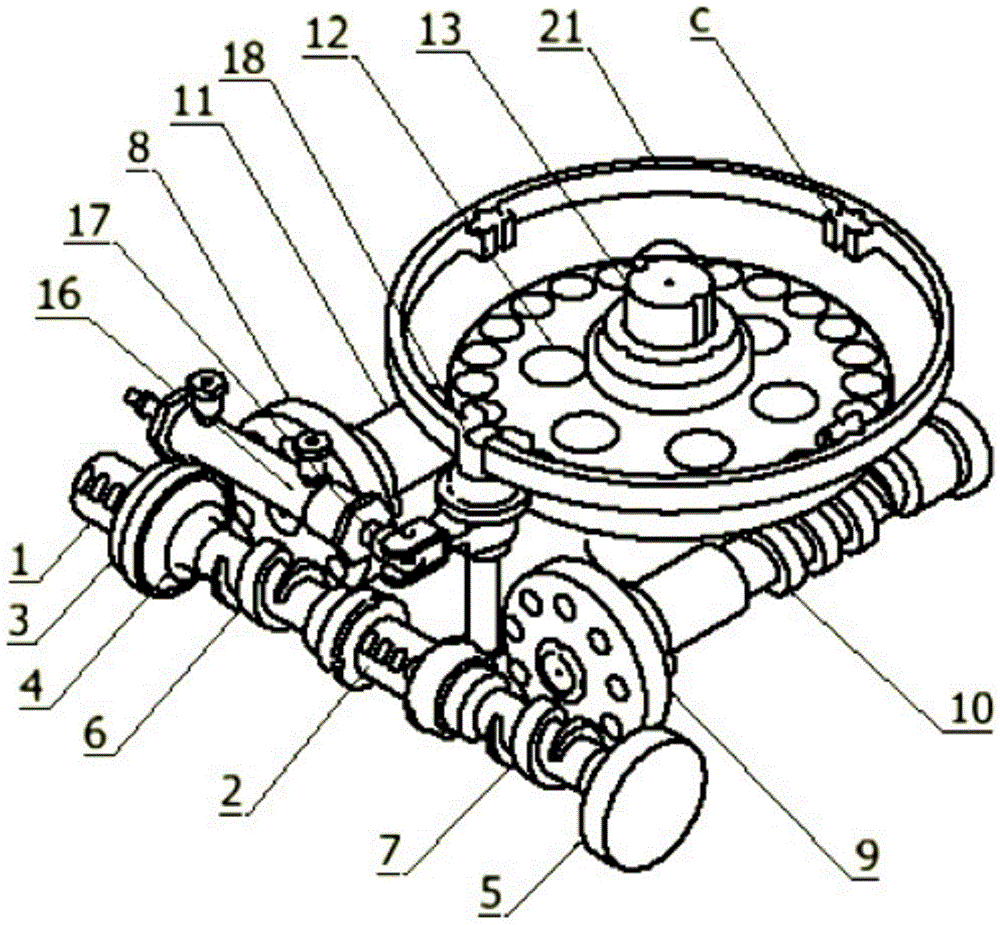

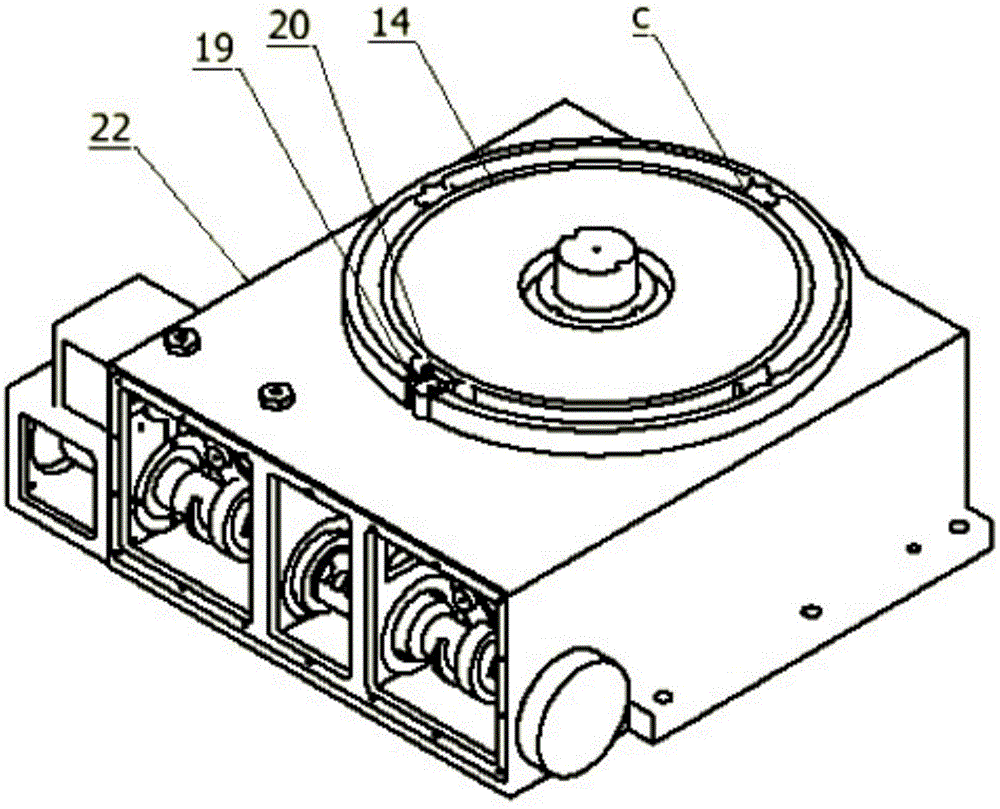

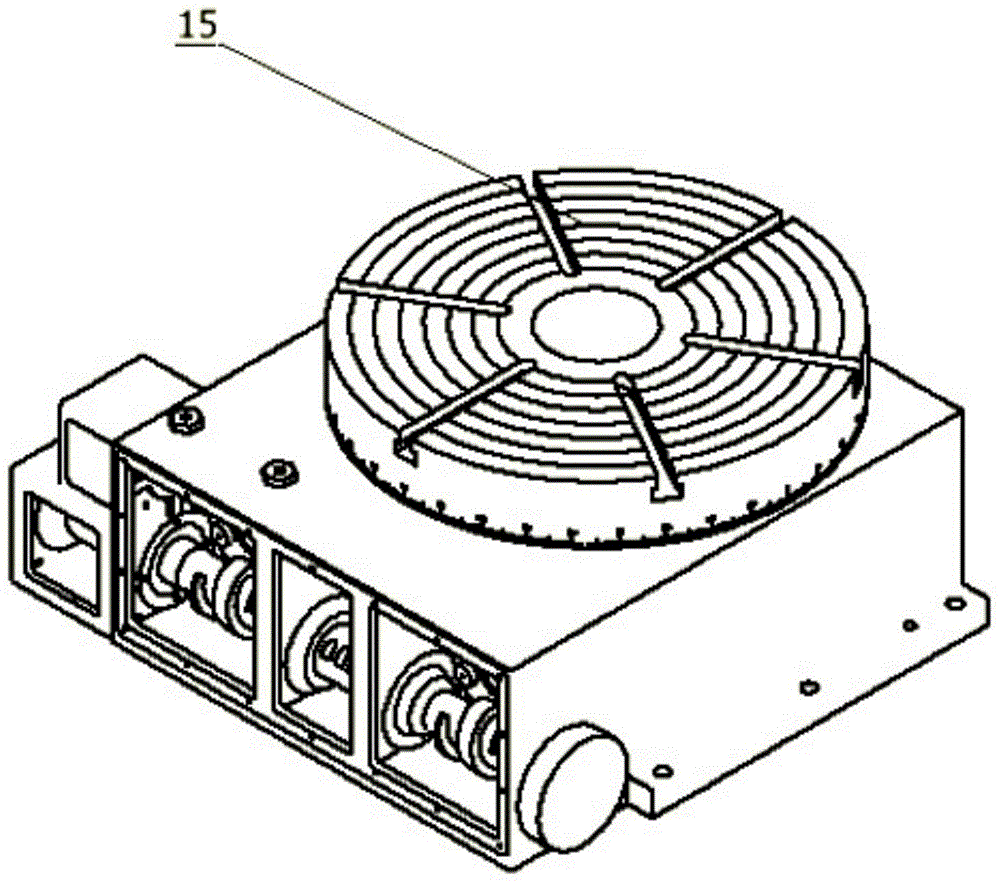

[0019] The present invention is an ultra-high-precision positioning rotary table with no-gap cam and worm transmission, which is composed of an indexing pre-tightening transmission mechanism, a positioning plate 14, a rotary table 15, a clamping mechanism for the rotary table, and a box body. The pre-tightening transmission mechanism is a two-stage cam worm transmission mechanism, and its primary cam worm transmission mechanism is divided by two primary transmission cam worms 6, 7, an elastic coupling 1, a rigid coupling 2 and two primary cams. Dials 8 and 9 are formed, and the rigid coupling 2 is connected between the two primary transmission cam worms 6 and 7. The rigid coupling 2 can be loosened or tightened so that the two primary transmission cam worms 6 and 7 are When the rigid coupling 2 is loosened, it can rotate independently, and when it is tightened, it can rotate together; the two primary cam index plates 8, 9 correspond to the two transmission cam worms 6, 7 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com