A two-deck positioning guide rail mechanism

A technology for positioning guide rails and second decks, applied in the direction of detachable decks, etc., can solve the problems of affecting the positioning effect of the second deck, damage to the bulkhead track, waste of cabin space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

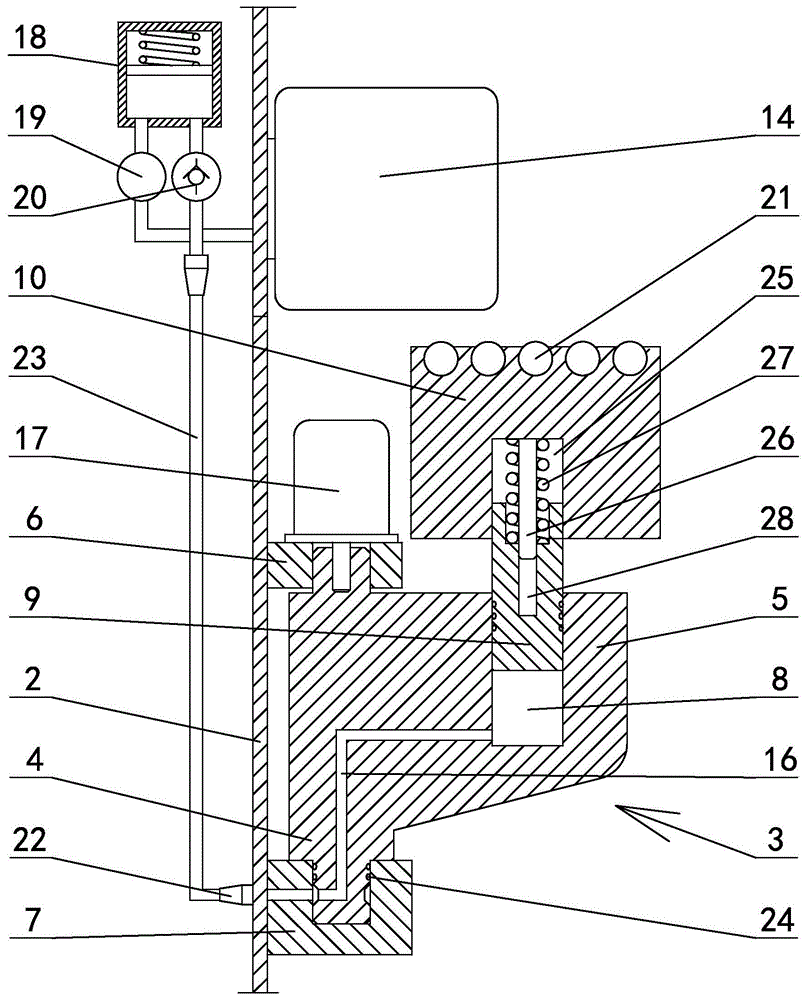

[0035] exist figure 1In the shown embodiment 1, a two-deck positioning guide rail mechanism is arranged on the bulkhead of a multi-purpose ship, including four strip-shaped guide rail frames fixed on the bulkhead and perpendicular to the bottom plate of the cabin, and the cross section is L-shaped. The second deck positioning guide rail 1 is fixed on the side of the guide rail frame away from the bulkhead and parallel to the guide rail frame. A corbel support 3 is provided on the same height of the guide rail frame 2. The corbel support includes a The pivot shaft 4 and the support body 5 arranged on one side of the pivot shaft, the upper and lower ends of the pivot shaft are respectively connected to the upper pivot seat 6 and the lower pivot seat 7, the upper pivot seat and the lower pivot seat and the guide rail The support body is provided with a lower oil cylinder 8 whose axis is parallel to the guide rail frame, and the upper end of the lower oil cylinder piston 9 adapted...

Embodiment 2

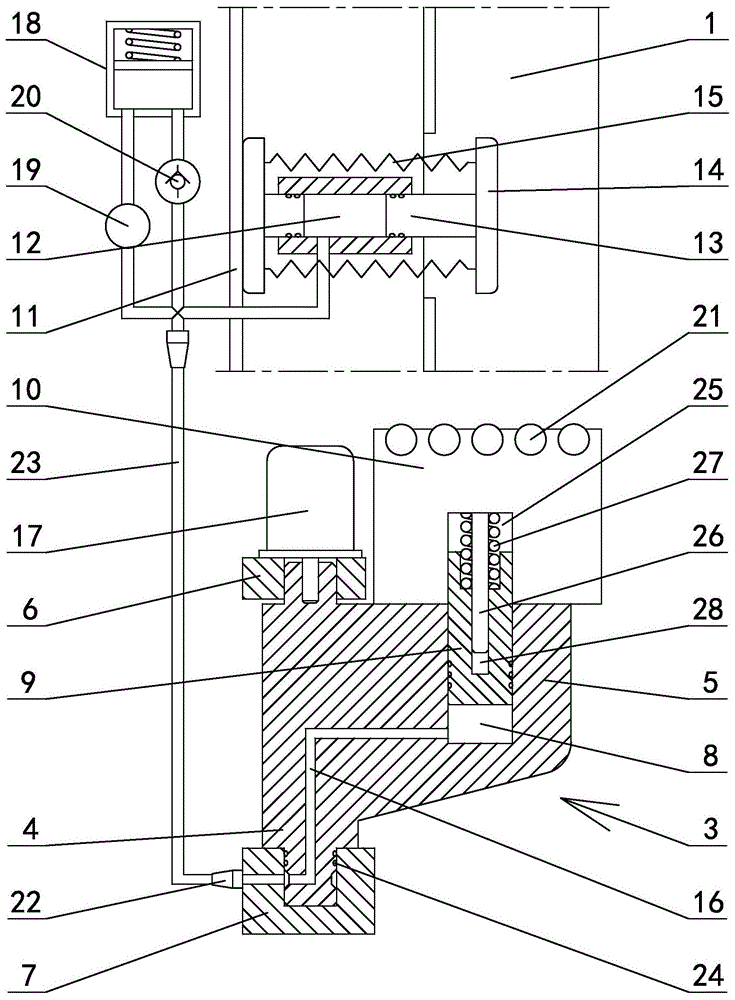

[0038] The corbel support and upper oil cylinder of embodiment 2 are arranged on the guide rail frame through the synchronous lifting mechanism (see Figure 5 ), the lifting mechanism includes a corbel support lifting guide rail 29 arranged on the guide rail frame and parallel to the guide rail frame and a corbel support drive box 30 arranged on the corbel support lift guide rail, and the corbel support drive box is L-shaped as a whole , the cross-section of the corbel support lifting guide rail is cross-shaped (see Figure 10 , Figure 11 ), including the fixed plate 31 and the limit strips 32 symmetrically arranged on both sides of the fixed plate, one side of the fixed plate is fixed on the guide rail frame between the second deck positioning guide rail and the bulkhead, and the other side of the fixed plate There are tooth grooves 33, and the limit chute 34 is formed between the limit strips on both sides of the fixed plate, the fixed plate and the guide rail frame; the c...

Embodiment 3

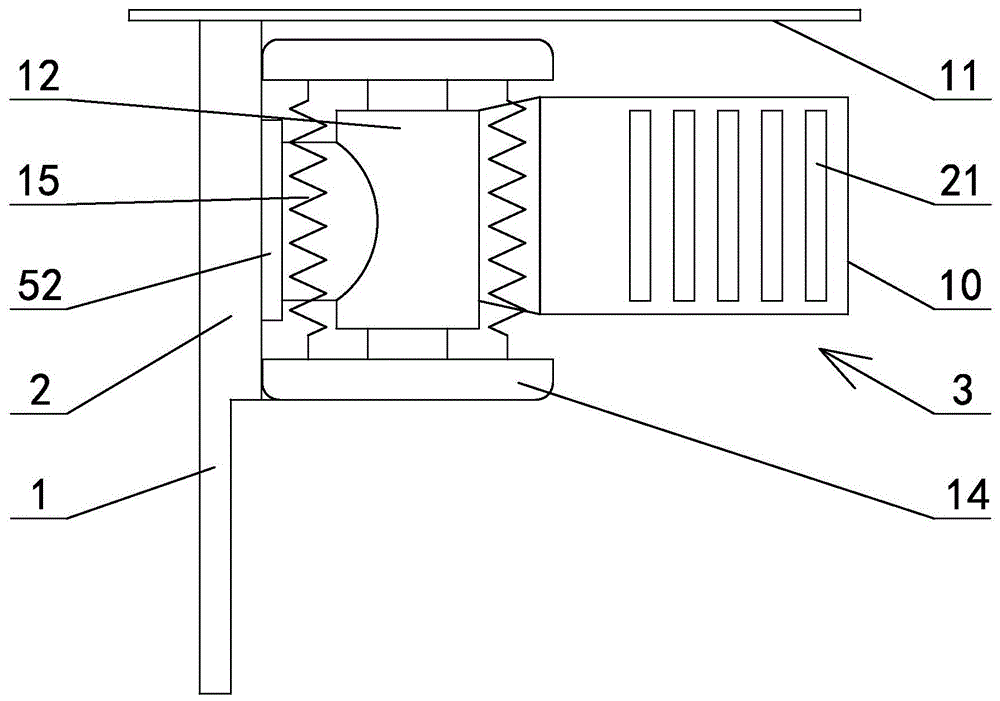

[0042] The inboard of the two deck positioning guide rails of embodiment 3 is provided with guide slide plate (see Figure 8 ), the guide slide plate is composed of 2-4 guide assemblies sequentially connected, and in this embodiment there are 3 (see Image 6 ), the cross-section of the guide assembly is L-shaped, and is composed of a left slider 44 and a right slider 45 that are respectively slidingly matched with the two inner sides of the second deck positioning guide rail and hingedly formed, and the left slider and the right slider face the side of the second deck positioning guide rail There is a roller groove perpendicular to the positioning guide rail of the second deck, and rollers are arranged in the roller groove, and the outer edges of the left slide plate and the right slide plate are bent to form a positioning groove 46 adapted to the outer edge of the positioning guide rail of the second deck. The two guide assemblies are hinged to each other through the slide pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com