Clinker silo for containerized bulk conveyor

A container and conveyor technology, applied in the field of container bulk conveyor clinker bins, can solve the problems of cargo damage, poor environment, pollution, easy damage of goods, etc., and achieve the effect of alleviating pollution problems and improving the degree of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

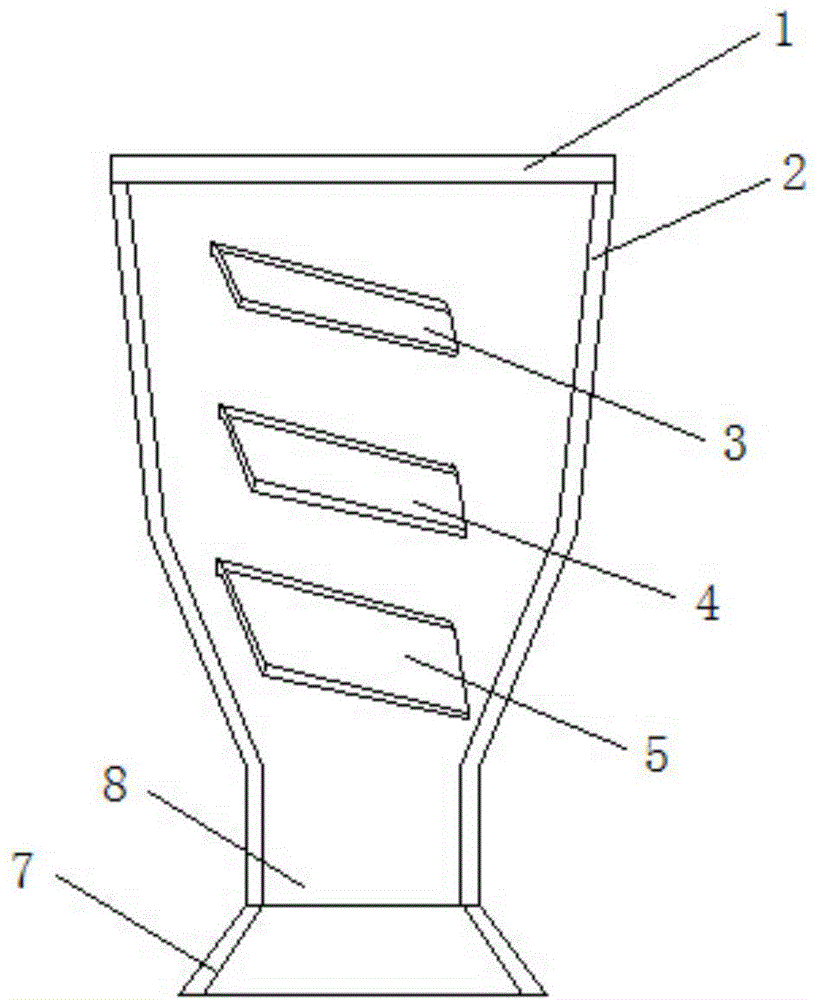

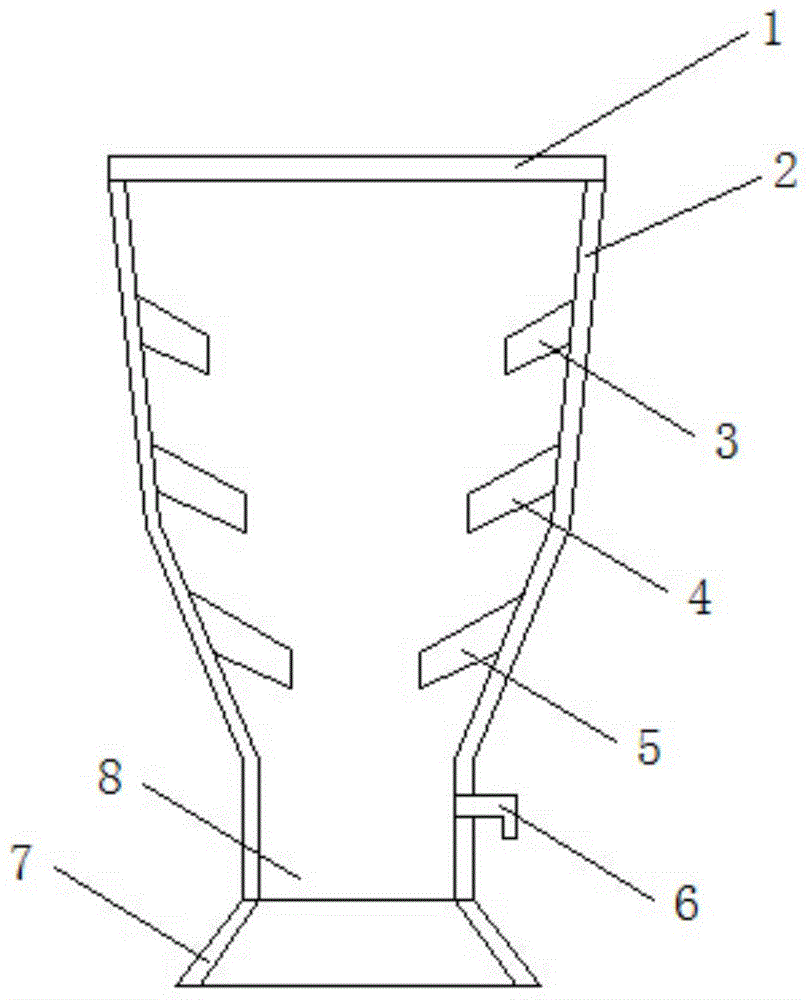

[0014] The preferred embodiment 1 of the container bulk conveyor clinker bin of the present invention, as figure 1 , 2 As shown, it includes the clinker bin body 2, the feed port 1 at the top of the clinker bin body 2 and the discharge port 8 at the bottom of the clinker bin 2, and the inner walls of the clinker bin 2 are respectively A primary baffle plate 3, a secondary baffle plate 4 and a tertiary baffle plate 5 are fixed, and the primary baffle plate 3, the secondary baffle plate 4 and the tertiary baffle plate 5 are all along the inner wall of the clinker bin 2 toward the clinker. The direction of the center of the feed bin 2 is inclined downward, and the lengths of the primary baffle plate 3, the secondary baffle plate 4 and the tertiary baffle plate 5 along the inner wall of the clinker silo 2 toward the center of the clinker silo 2 are sequentially In addition, the bottom of the outlet 8 is provided with an outwardly extending baffle 7 . The primary baffle 3 , secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com